Display device, display panel and manufacture method thereof

A technology for a display panel and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems that light-emitting units are easily eroded by water vapor and oxygen, and achieve the effect of improving service life and increasing distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

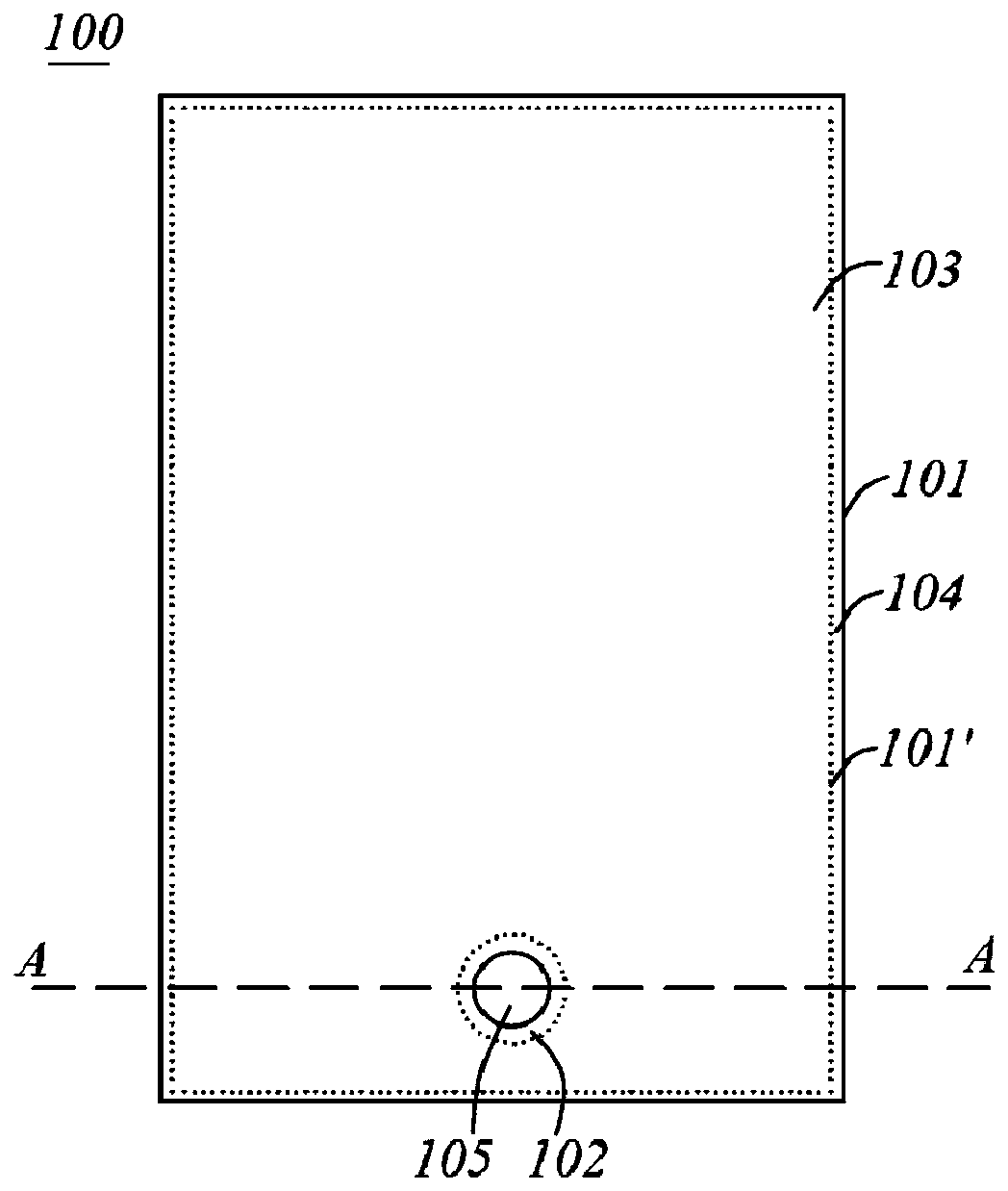

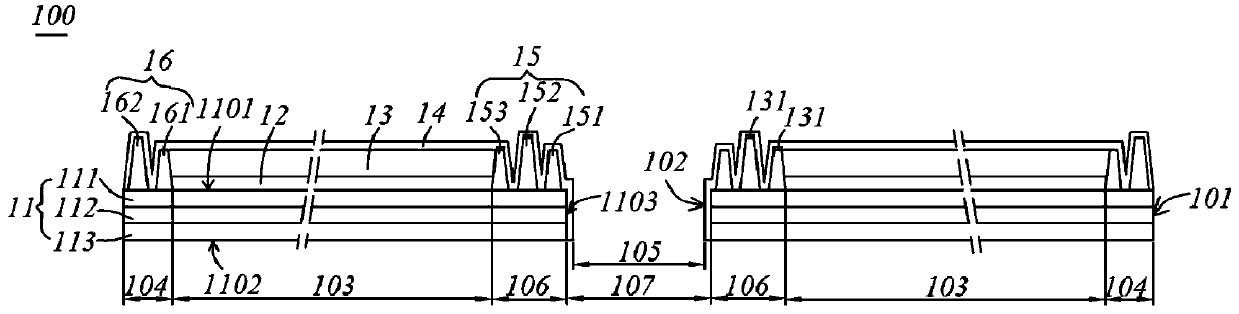

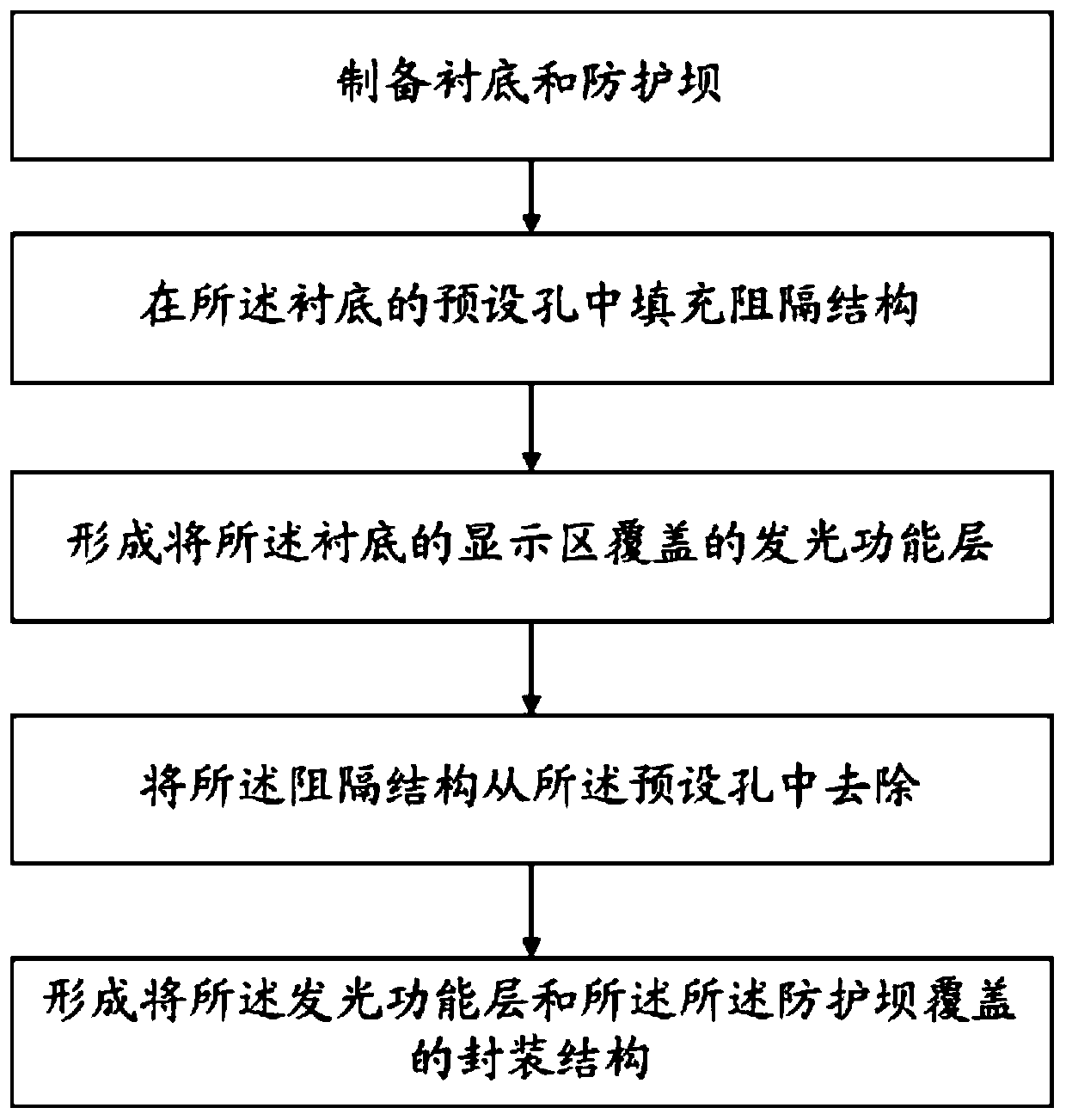

[0060] refer to Figure 1 to Figure 2 An embodiment of the present invention is shown, which provides a display panel 100 . It is preferably set as an organic light emitting display panel, especially an active matrix organic light emitting display panel. The following display panel 100 mainly uses an active matrix organic light emitting display panel as an implementation mode to introduce its specific structure.

[0061] The display panel 100 is roughly in the shape of a thin plate extending along the first surface (that is, it has a relatively large surface area on the first surface and a very small span in the vertical direction of the first surface). figure 1 The projection diagram shown in is along the vertical direction of the first surface. It should be noted that, in the drawings of the present application, the first surface is roughly illustrated as a plane, but in actual implementation, for example, when the display panel 100 is set as a flexible structure, the first...

Embodiment 2

[0139] see Figure 6 , which illustrates another specific implementation of the display panel 100 .

[0140] It is worth noting that this embodiment contains many of the same features as in Embodiment 1, and for the sake of brevity, detailed descriptions of many of the same features are omitted here, and the same symbols used in these drawings and descriptions represent the same components . For example, the structure of the second protection dam in this embodiment is the same as that in Embodiment 1, and both are marked as the second protection dam 16 . For the components in this embodiment that are different from those in Embodiment 1, the combination of the label of the corresponding component in Embodiment 1 and the letter "a" is used to distinguish it from Embodiment 1. For example, in this embodiment and the implementation In Example 1, all have the first protection dam but the specific structure of the first protection dam is different, so it is marked as the first pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com