Frame sealing adhesive, preparation method thereof, display panel and preparation method thereof

A display panel and frame sealing adhesive technology, which is applied in the direction of adhesive products, chemical instruments and methods, adhesives, etc., can solve problems such as the difficulty of bending the sealing adhesive, affecting product reliability, and damage to the sealing adhesive, so as to ensure the packaging performance , Strengthen the binding force and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment aims at that when the existing flexible display device is bent, the hardened sealant often makes it difficult to bend, and even in the process of bending, the hardened sealant is damaged due to greater stress, thus affecting the In order to solve the problem of product reliability, a frame sealant and its preparation method are provided. The frame sealant has excellent bending properties and can effectively relieve the stress on the frame of the flexible display panel when it is bent, thereby avoiding the failure of the flexible display panel when it is folded. Or defects occur during the bending process, thereby ensuring that the sealant in the flexible display panel is damaged.

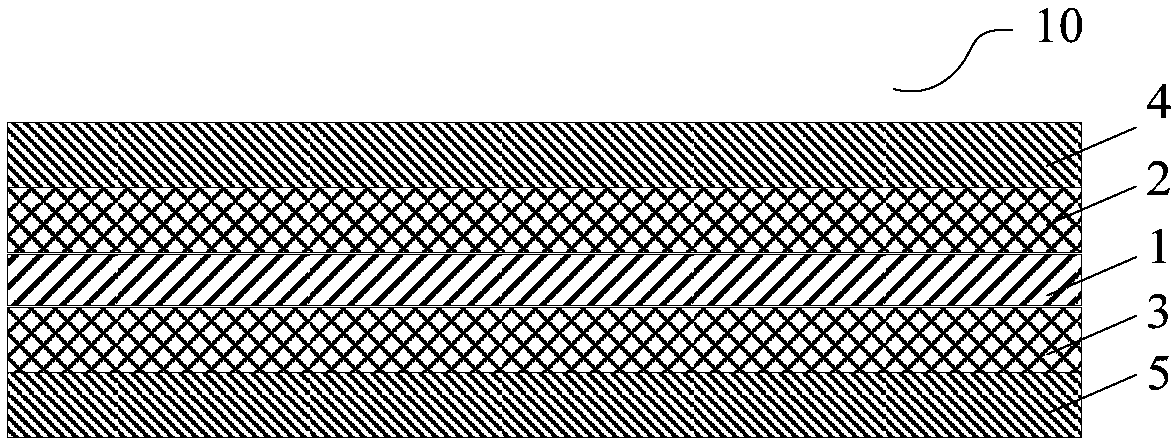

[0055] The flexible frame tape includes at least a base material and adhesive layers symmetrically arranged on both sides of the base material, wherein the base material is an elastomer material, and the adhesive layer is formed of a material including an elastomer material and...

Embodiment 2

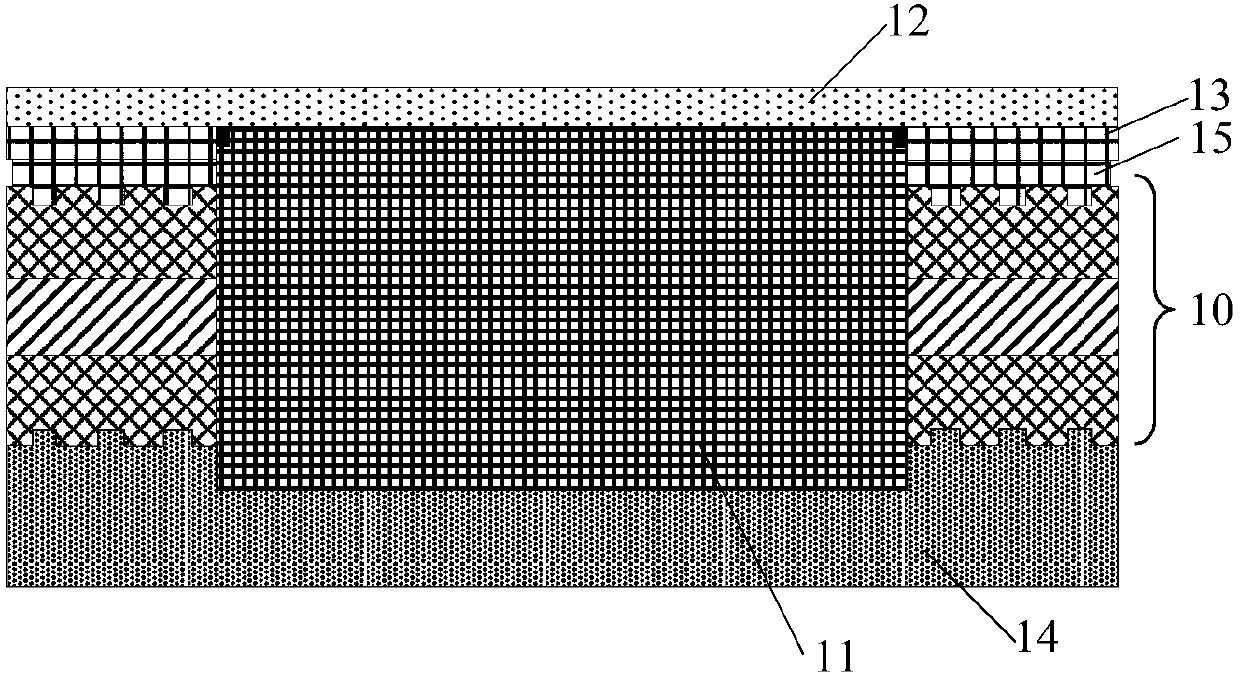

[0084] This embodiment provides a display panel, the display panel includes a flexible display module, and the flexible display module is packaged with the sealant in Embodiment 1. The frame sealant can effectively relieve the stress on the frame of the flexible display device when it is bent, and while realizing the flexible display, it also has a better packaging effect and can ensure its performance when being folded or bent.

[0085] Wherein, the flexible display module here may be an LCD display device or an OLED display device.

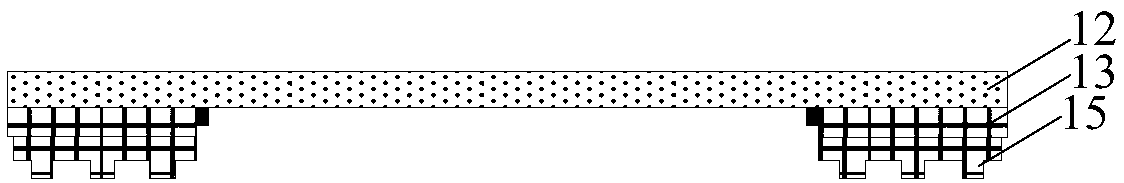

[0086] In the flexible display panel of this embodiment, if figure 2 As shown in the cross-sectional view of the concave-convex structure shown, both sides of the flexible display panel are respectively provided with a flexible cover 12 (Cover Film) and a middle frame 14, the flexible cover 12 is used to protect the display module 11, and the middle frame 14 is used to support The display module 11, the flexible cover 12 and the middle frame 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com