Curable silicone resin composition, cured product thereof, and opaque silicone adhesive sheet formed from the composition

A resin composition, silicone technology, applied in nonlinear optics, optics, adhesives, etc., can solve problems such as poor practicability, increased cost, and reduced internal curability, and achieves difficult separation and sedimentation, prevents wrong operation, and has good shading properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] Hereinafter, the present invention will be specifically described by giving synthesis examples, examples, and comparative examples, but the present invention is not limited by the following examples. In addition, the weight average molecular weight in the following example is the polystyrene conversion value measured by gel permeation chromatography (GPC).

Synthetic example 1

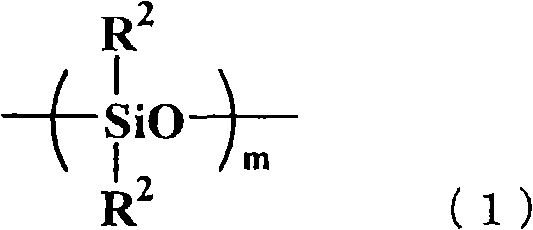

[0114] -Organopolysiloxane resin containing vinyl group (A1)-

[0115] PhSiCl 3 Represented organosilane: 1142.1g (87.1 mol%),

[0116] ClMe 2 SiO(Me 2 SiO) 33 SiMe 2 Cl: 529g (3.2 mol%),

[0117] MeViSiCl 2 : 84.6 g (9.7 mol %) was dissolved in toluene solvent, added dropwise to water, co-hydrolyzed, washed with water, neutralized by alkaline washing, dehydrated and then desolventized to synthesize vinyl-containing resin (A1) . This resin is a solid having a weight average molecular weight of 62,000 and a melting point of 60°C. The resin had a vinyl content of 0.05 mol / 100 g.

Synthetic example 2

[0119] -Organopolysiloxane resin (B1) containing hydrosilyl group (Hiderosilyl)-

[0120] PhSiCl 3 Represented organosilane: 1142.1g (87.1 mol%),

[0121] ClMe 2 SiO(Me 2 SiO) 33 SiMe 2 Cl: 529g (3.2 mol%),

[0122] MeHSiCl 2 : 69g (9.7 mol %) dissolved in toluene solvent, added dropwise to water, co-hydrolyzed (co-hydrolyzed), then washed with water, neutralized by alkali washing, dehydrated and desolventized, and synthesized containing hydrosilane base resin (B1). This resin is a solid having a weight average molecular weight of 58,000 and a melting point of 58°C. The silyl group content of this resin was 0.05 mol / 100 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com