Display panel and manufacturing method thereof, and display device

A display panel and display area technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems affecting OLED life, packaging failure, inorganic packaging layer damage, etc., to ensure life and avoid packaging failure , to avoid the effect of thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

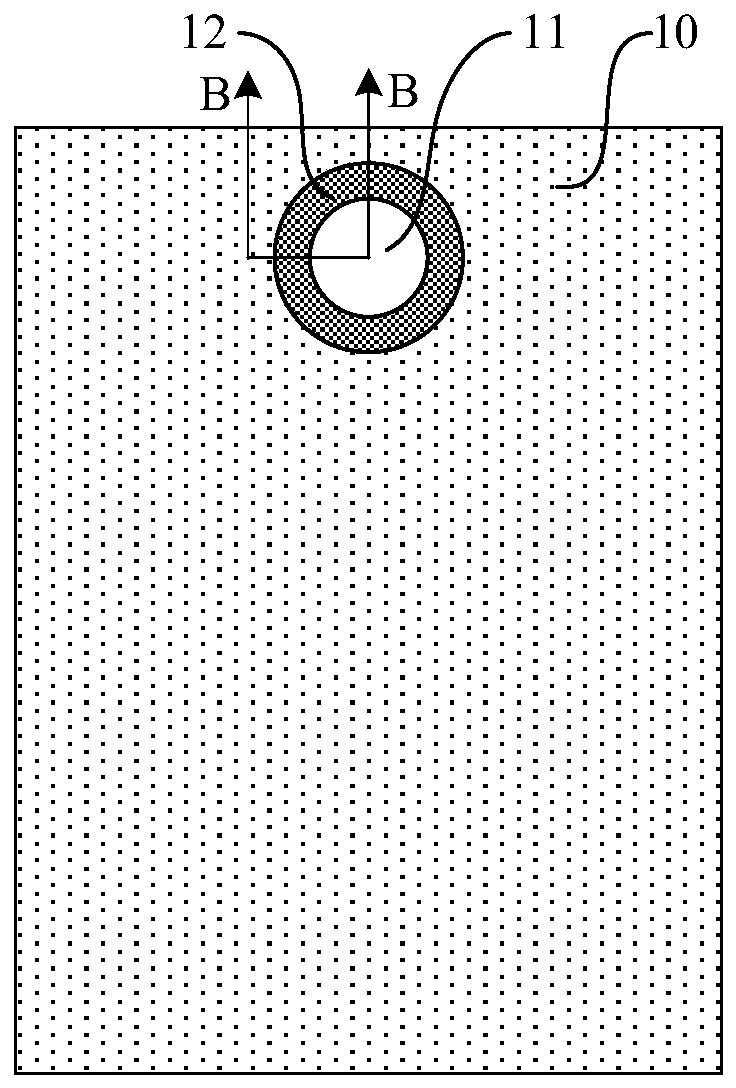

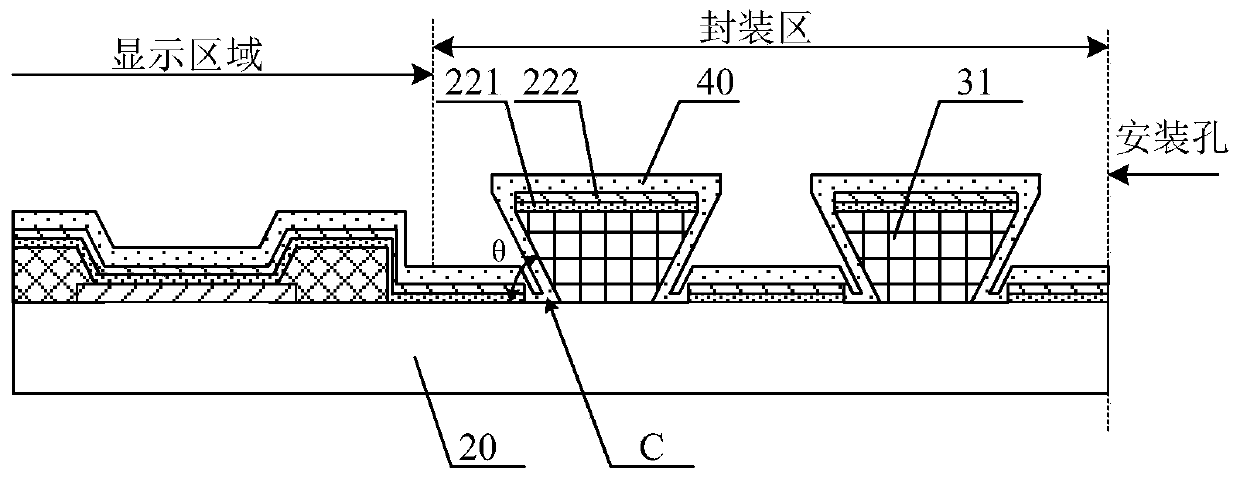

[0067] The schematic diagram of the planar structure of the display panel of the embodiment of the present invention is as Figure 2a As shown, image 3 The display panel of the first embodiment of the present invention Figure 2a Schematic diagram of the B-B section in Figure 4 for image 3 An enlarged schematic diagram of part C in. The display panel of the embodiment of the present invention, such as Figure 2a with image 3 As shown, on a plane parallel to the display panel, the display panel includes a display area 10, a mounting hole 11 is provided in the display area 10, and a packaging area 12 between the display area 10 and the mounting hole 11 is provided around the mounting hole 11 .

[0068] Such as image 3 As shown, on a plane perpendicular to the display panel, the structure of the packaging area includes an isolation structure 30 disposed on the base substrate 20, and the isolation structure 30 is disposed around the mounting hole 11. The isolation structure 30 i...

no. 2 example

[0110] Based on the technical concept of the embodiment of the present invention, the embodiment of the present invention also proposes a method for manufacturing a display panel. The display panel includes a display area, a mounting hole located in the display area, and an encapsulation area provided between the mounting hole and the display area, and the preparation method includes forming the encapsulation area on the base substrate. An isolation structure, forming the isolation structure includes:

[0111] An isolation pillar located on the base substrate is formed in the packaging area, and the orthographic projection of the side of the isolation pillar close to the base substrate on the base substrate is located on the isolation pillar far from the base substrate One side is in the orthographic projection on the base substrate;

[0112] A gentle layer is formed in the encapsulation area, the gentle layer is located on both sides of the isolation column, the gentle layer incl...

no. 3 example

[0135] Based on the inventive concept of the foregoing embodiment, an embodiment of the present invention also provides a display device, which includes the display panel adopting the foregoing embodiment. The display device can be any product or component with a display function, such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com