Cam type limit folding mechanism for battery case

A battery casing and cam-type technology, which is applied in the field of cam-type limit folding mechanism for battery casings, can solve the problems of high use cost and maintenance cost, inconvenient use, complex structure, etc., and achieves convenient operation, simple structure, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

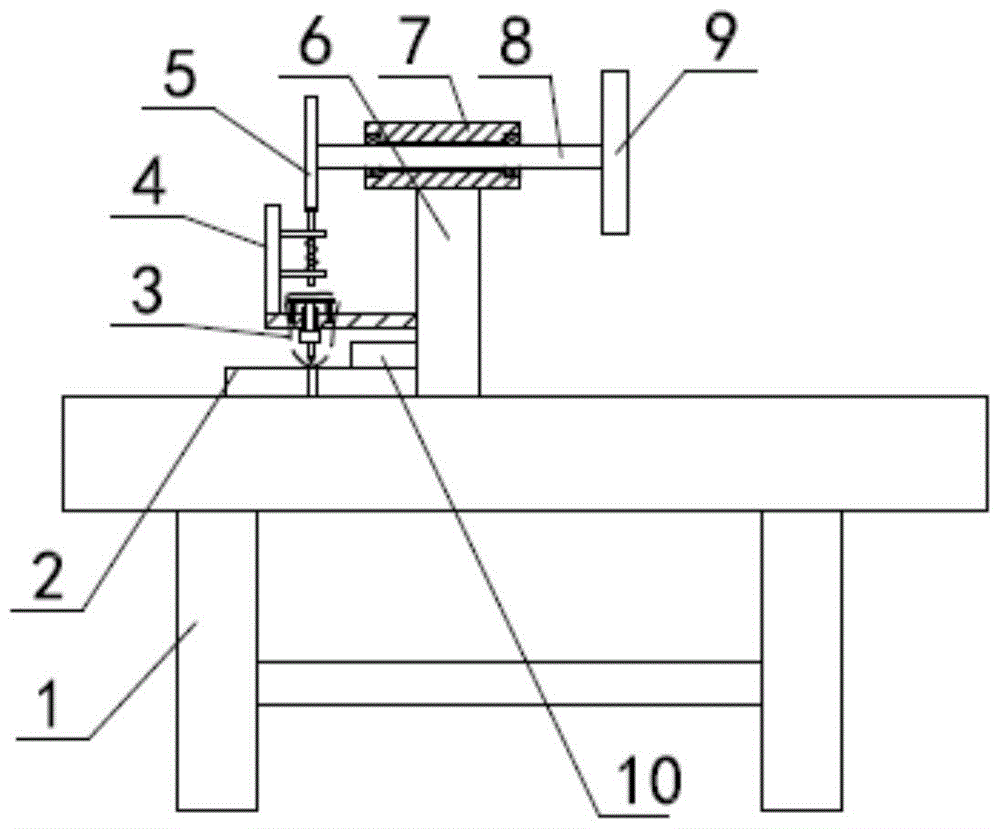

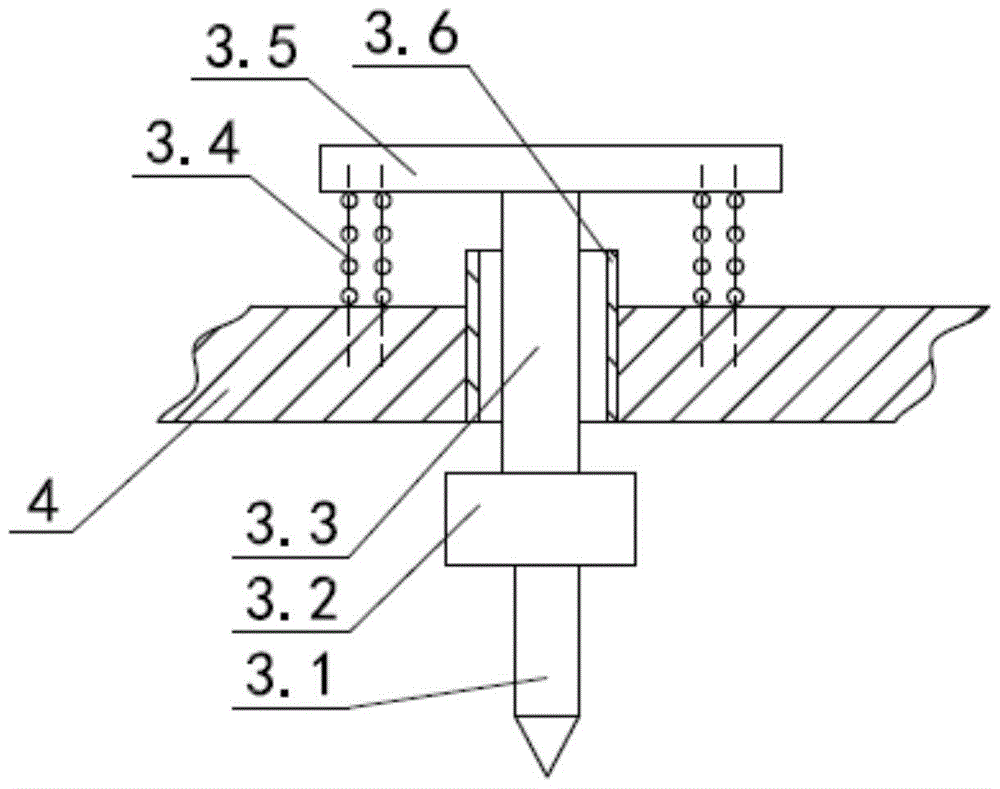

[0015] like figure 1 , figure 2 As shown, the battery casing uses a cam-type limit folding mechanism, including a workbench 1, on which a bottom mold 2 for folding is installed, and on the workbench 1 on the right side of the bottom mold 2, there is a vertically fixed installation Column 6, a casing 7 is installed horizontally on the mounting column 6, a rotating shaft 8 is installed horizontally on the casing 7, a handle plate 9 for rotation is installed on the right end of the rotating shaft 8, and the corresponding bottom mold 2 is provided directly above it. For the hemming reset mechanism 3 of the hemming, the hemming resetting mechanism 3 includes the mounting bracket 4 fixed on the mounting column 6, the hemming knife 3.1 and the transmission rod 3.3 for moving up and down, and the hemming knife 3.1 is installed on the The lower end of the transmission rod 3.3 is covered with a sliding sleeve 3.6 on the transmission rod 3.3, and the sliding sleeve 3.6 is mounted on th...

Embodiment 2

[0019] This embodiment is changed on the basis of the first embodiment, and the height of the workbench 1 is changed to 1000 mm. Others are the same as embodiment one.

Embodiment 3

[0021] This embodiment is changed on the basis of the first embodiment, and the height of the workbench 1 is changed to 1100 mm. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com