Folding machine for machining cable bridge frame

A technology for a cable tray and a folding machine, which is applied in the field of folding machines, can solve problems such as the efficiency limitation of folding, and achieve the effects of improving production efficiency, having a simple and compact structure and preventing arc bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

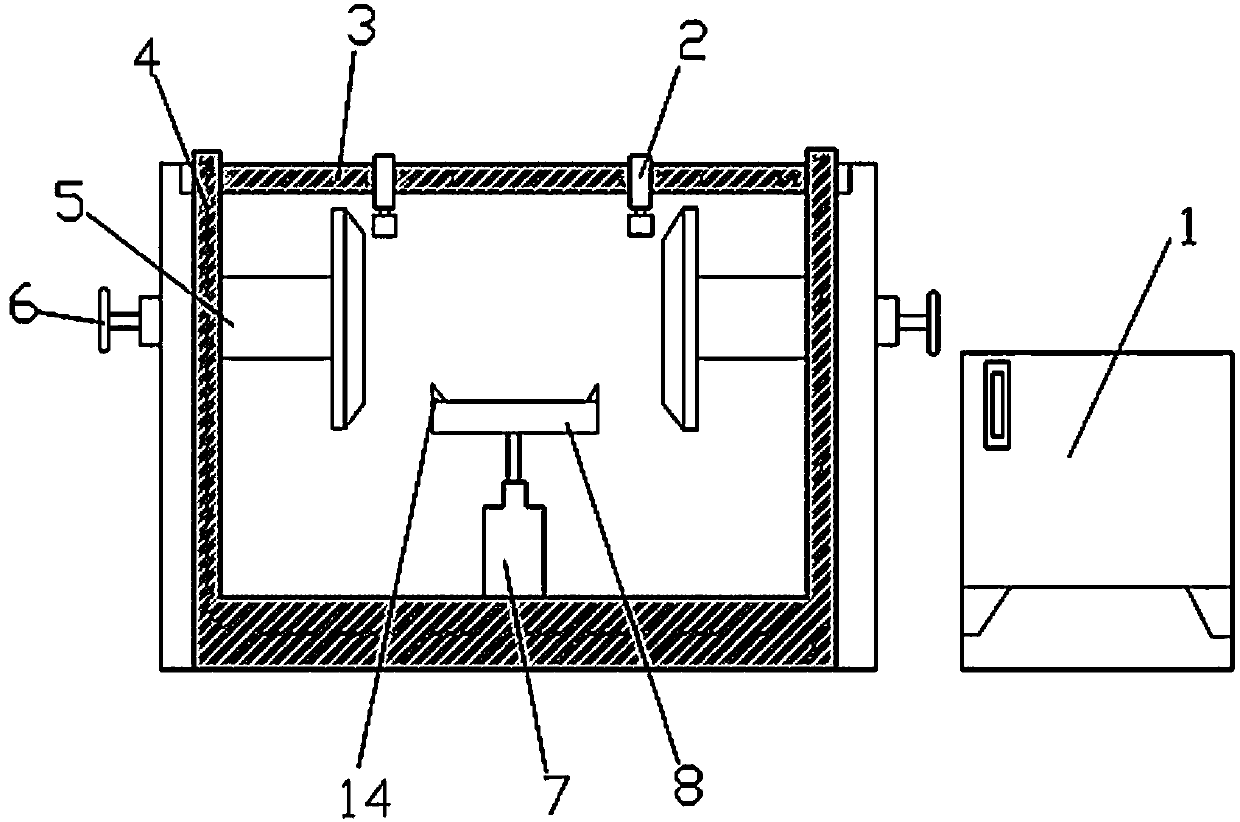

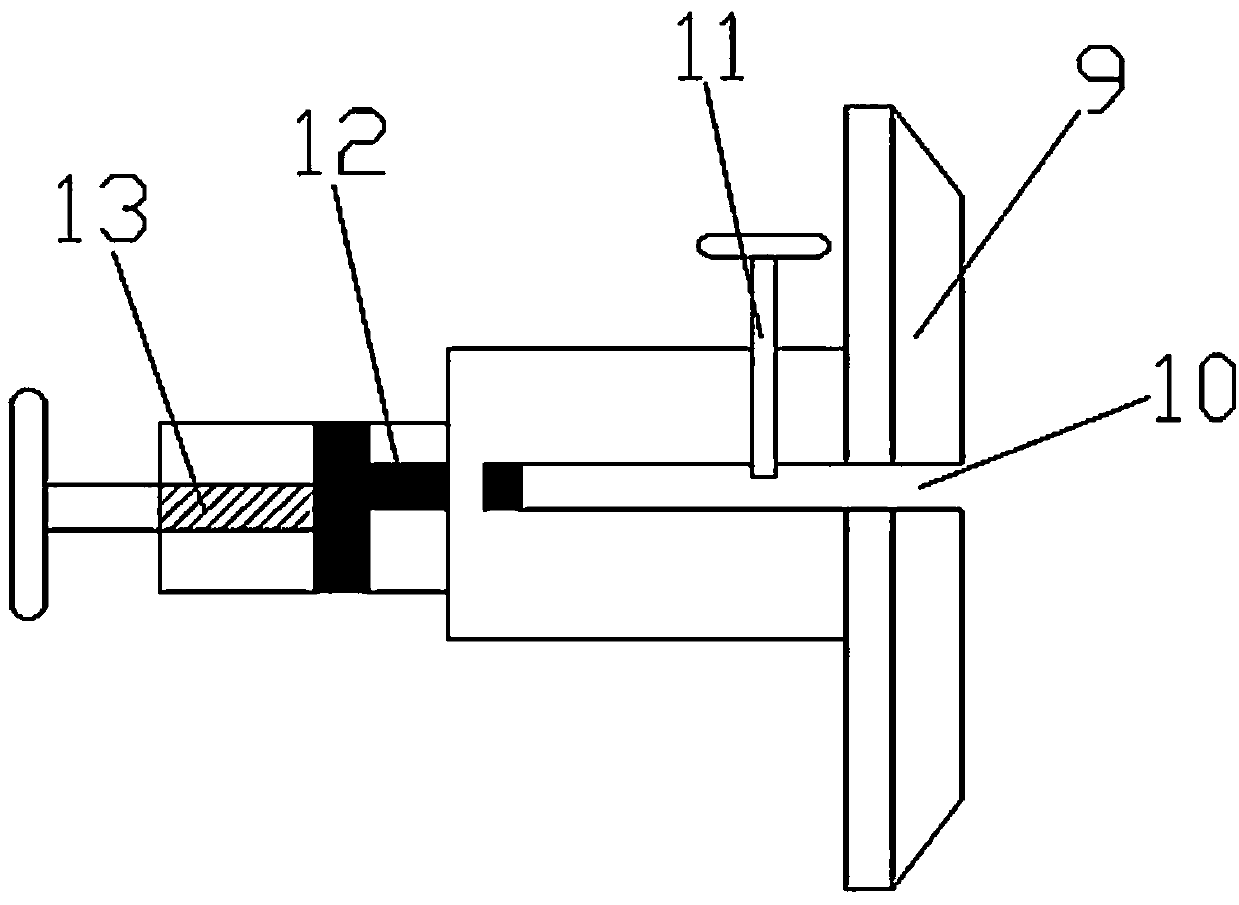

[0015] Figure 1-2 The specific embodiment of the present invention is shown: an edge folding machine for processing cable trays, including a hydraulic station 1, a laser positioning device 2, a beam 3, a frame 4, a plate fixing device 5, a limit device 6, and a hydraulic ejector rod 7 and the hemming platform 8, the beam 3 is fixedly arranged on the frame 4, two laser positioning devices 2 are arranged on the beam 3, the plate fixing device 5 is symmetrically arranged on both sides of the frame 4, and the limit device 6 is arranged on the plate On the fixing device 5, the hydraulic ejector rod 7 is set at the bottom of the frame 4, between the two plate fixing devices 5, the hemming platform 8 is arranged on the hydraulic ejector rod 7, and the hydraulic station 1 is independently installed, connected to the hydraulic ejector rod 7 The connection structure between the hemming platform 8 and the hydraulic ejector rod 7 is connected by a spiral structure, and printing knives 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com