Cement-stabilized-macadam mixture design method

A cement-stabilized gravel and design method technology, applied in the field of road engineering, can solve the problems of reduced bending and pulling capacity and cement stability, small cement content in local mixtures, dry and white coarse aggregate surface, etc., to achieve easy paving and compaction, less voids, good fluidity

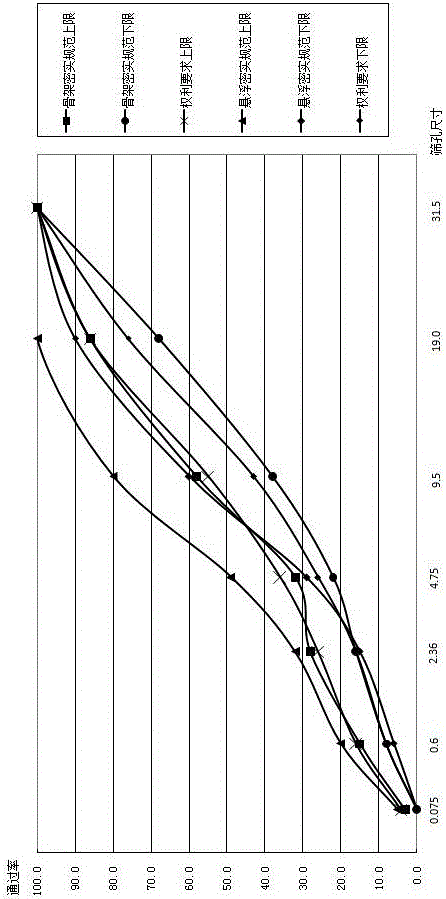

Active Publication Date: 2017-02-22

SHANDONG TRANSPORTATION INST

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the large specific surface area of fine aggregate, in the traditional design method, the cement binder is largely adsorbed by the fine aggregate, resulting in uneven mixing, and the surface of the coarse aggregate is often dry and white, and the fine aggregate is rarely bonded, and the cement is hydrated. Insufficient and local mixtures with low cement content, reduced bending and tensile strength and cement stability, and a large amount of cement required to meet the design standards, easy to segregate during loading, unloading, transportation and rolling, and local cracks are prone to appear, which affects the service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0036] Unless otherwise specified, the percentages used below are all percentages by weight

[0037] Raw materials:

[0038] 1. Cement: Ordinary Portland Cement (P·O)

[0039] 2. Coarse aggregate: limestone 20-30mm, 10-20mm, 5-10mm

[0040] 3. Fine aggregate: limestone 0-5mm

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cement-stabilized-macadam mixture design method, and belongs to the field of road engineering. The cement-stabilized-macadam mixture design method is characterized in that the fractional step mixing method is adopted in the mixture mixing process, the rotating compaction forming method is combined, and a test piece is obtained. Compared with an existing design method, by means of the cement-stabilized-macadam mixture design method, the technical problem that as the actual compaction state of a pavement-base construction site cannot be reflected in the traditional design process, the performance of the mixture is uneven is solved, the using amount of cement and the using amount of water are reduced on the premise that the performance requirements can be met, the aims that the design performance of the mixture is stable, economical and environmentally friendly are achieved, and the cement-stabilized-macadam mixture design method has the quite-good popularization and application value.

Description

technical field [0001] The invention relates to the field of road engineering, and specifically provides a method for designing a cement-stabilized gravel mixture. Background technique [0002] Semi-rigid base pavement is the main structural form of expressways in my country. The base is the main load-bearing layer of the pavement, and the main material of the base is cement stabilized mixture. Due to the large specific surface area of fine aggregate, in the traditional design method, the cement binder is largely absorbed by fine aggregate, resulting in uneven mixing, and the surface of coarse aggregate often appears dry and white, fine aggregate is rarely bonded, and cement hydration Insufficient and local mixtures with low cement content will reduce the bending and tensile capacity and cement stability, and the amount of cement required to meet the design standards will be large. It is easy to segregate during loading, unloading, transportation and rolling, and local cra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04

CPCC04B28/04C04B2201/20C04B2201/50C04B14/28

Inventor 闫翔鹏韦金城申全军马士杰阎肖宇韩文扬余四新孙强陈婷婷季正军董昭

Owner SHANDONG TRANSPORTATION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com