Ballastless track railroad roadbed surface water sealing layer structure

A technology for railway subgrades and ballastless tracks, which is applied to roads, tracks, ballast layers, etc., can solve problems such as easy cracking of waterproof structures, pulverization, and difficulty in guaranteeing waterproof effects, and achieve improved ultraviolet aging, strong deformation adaptability, Quality Control Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

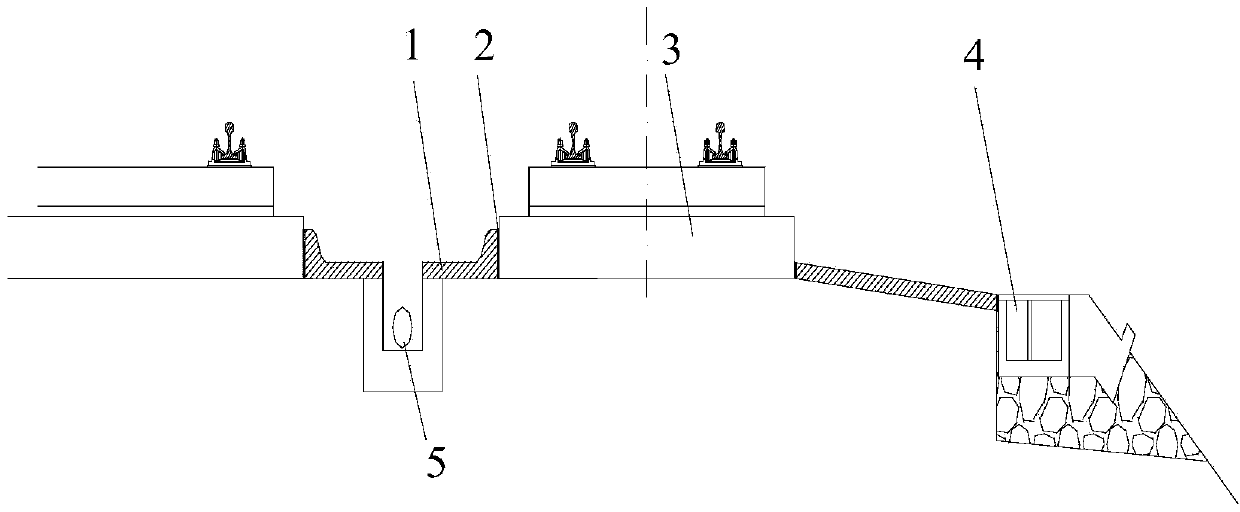

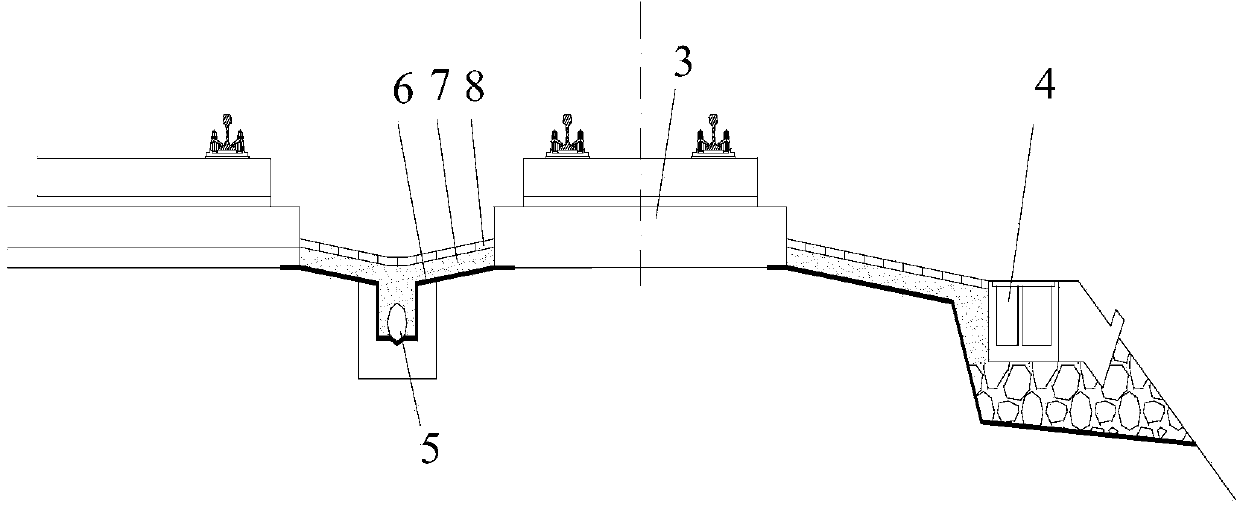

[0018] The technical solutions of the present invention will be further described below with reference to the accompanying drawings. figure 2 The water-sealing layer structure of the ballastless track railway subgrade surface of the present invention is shown, including a water barrier layer 6, a prefabricated pavement 8 and a sand cushion layer 7. The sand cushion layer 7 is arranged on the water barrier layer 6, and the prefabricated pavement 8 is placed on top of the water barrier layer 6. On the sand cushion layer 7, the prefabricated pavement 8 forms the surface of the water sealing layer. The water barrier layer 6 is made of two-cloth-one-membrane geotechnical anti-seepage material, which is composed of plastic film and non-woven fabric.

[0019] The ballastless track railway subgrade surface water sealing layer structure is arranged on the subgrade surface inside and outside the track base, and has a transverse slope, which slopes obliquely downward from both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com