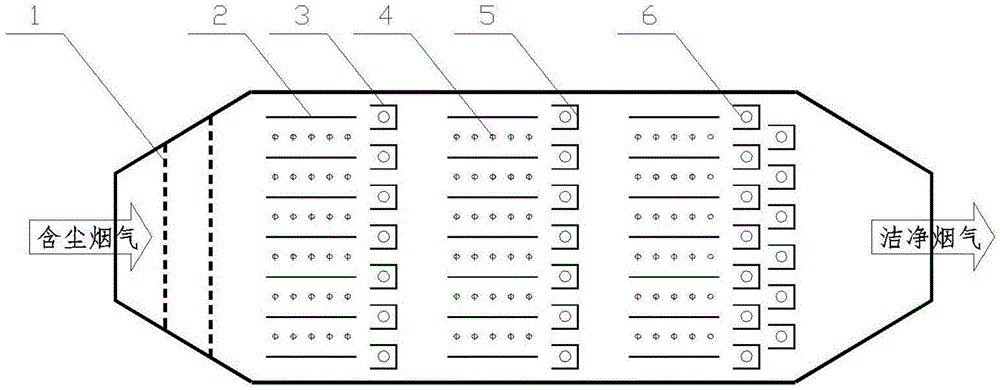

Filter-screen wet-type electric dust removing device and method

A technology of wet electrostatic precipitator and filter screen, which is applied in the field of electrostatic precipitator, can solve the problems of high installation process requirements, increased failure probability, and high investment cost, so as to avoid secondary dust pollution, improve dust collection efficiency, and promote airflow uniformity. cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] A method for a filter screen type wet electrostatic precipitator, comprising the following steps:

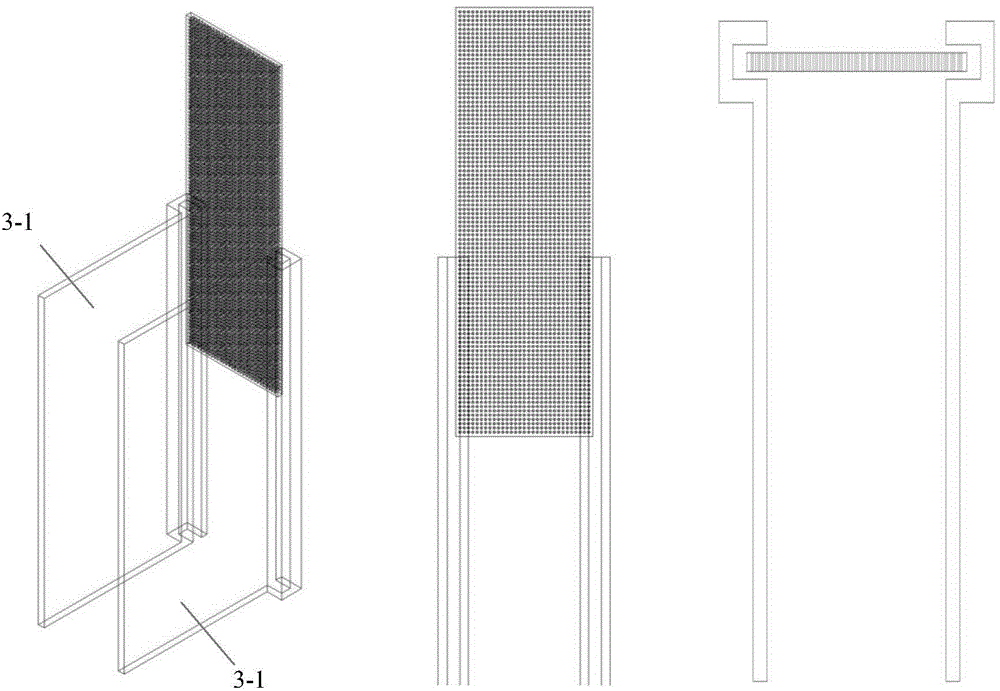

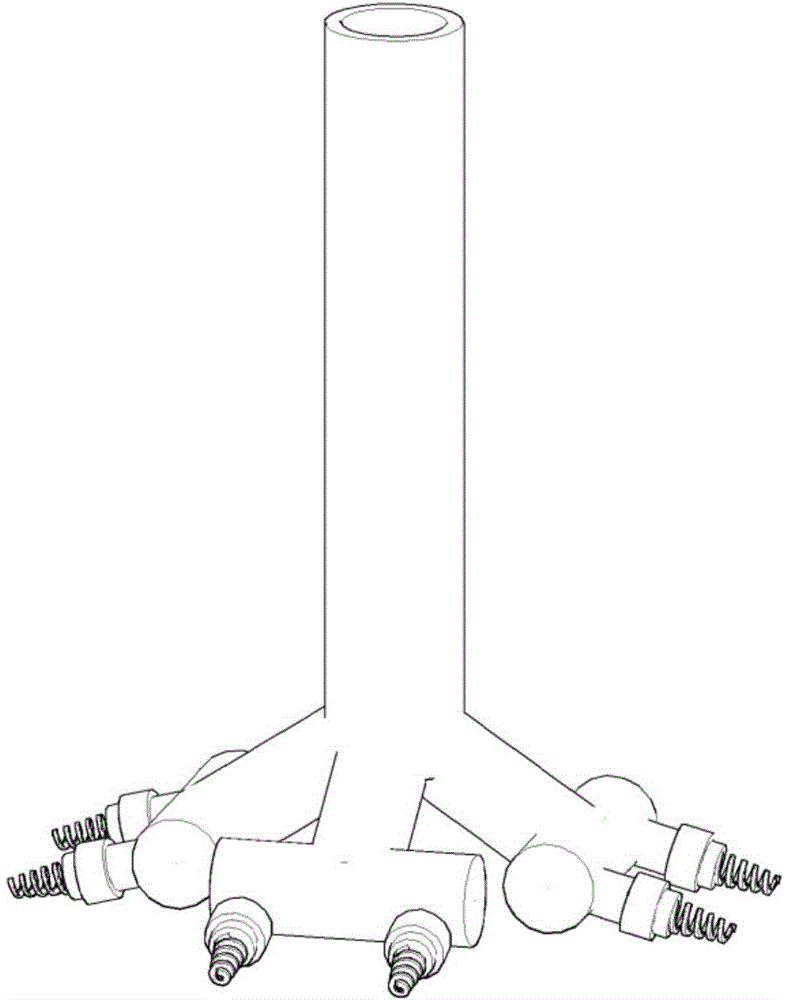

[0042] 1) The dusty flue gas mainly contains SO 2 , SO 3 , NO X and mercury and other pollutants, the dust-containing flue gas enters the filter-type wet electrostatic precipitator of the present invention through the flue gas inlet device, and first passes through the equalizing orifice plate 1 to evenly disperse the dust-containing flue gas into the flue gas treatment device for further processing. Dust removal; connect with the high-voltage rectifier transformer through the cathode line 4, and form a high-voltage charged electric field area in the flue gas treatment device together with the anode plate 2; The high-voltage corona discharge electrifies the dust particles in the dusty flue gas, and the charged dust particles are adsorbed on the anode plate 2 under the action of the electric field force; although most of the dust is close to the anode plate 2, due to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com