Electromagnetic heating pressure cooking device

A cooking device and pressure technology, applied in heating devices, cooking utensils, household appliances, etc., can solve the problems of complex shape of elastic mechanism, difficult to manufacture, safety of the lid flying out, etc., and achieve easy design and selection of materials and easy selection of materials. , the effect of good cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

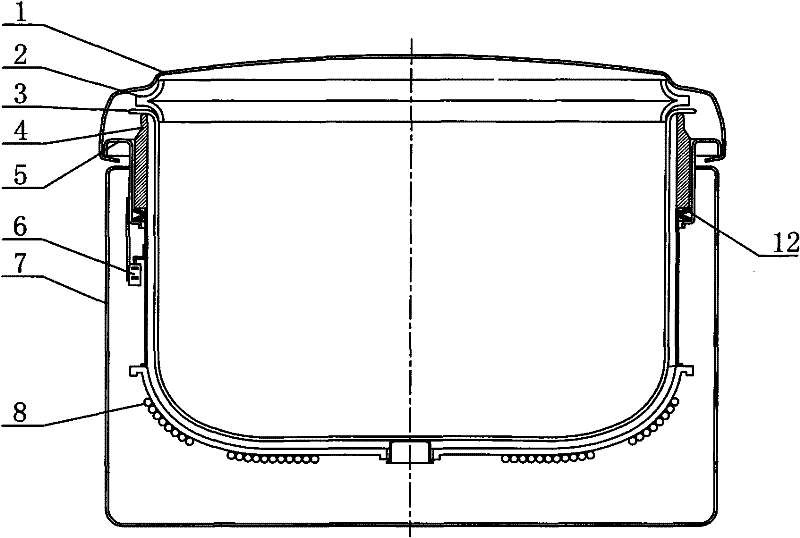

[0026] Such as figure 1 Shown, the present invention comprises pot cover 1, sealing ring 2, inner pot 3, shell 7, the outer pot ring 5 that is fixed in shell 7 and the displacement detection switch 6 that is connected with control circuit, pot cover 1 and outer The pot ring 5 is screwed and rigidly connected, and the inner pot 3 is sealed by the sealing ring 2; a pressure ring 4 and an elastic mechanism 12 are arranged between the inner pot 3 and the outer pot ring 5, and the stationary end of the elastic mechanism 12 is fixed on the outer pot ring 5 On the flanging part of the bottom; the outer protruding end surface of the pressure ring 4 is placed on the elastic mechanism; the pot edge of the inner pot 3 is in rigid contact with the top of the pressure ring 4, and the coil disk 8 is fixedly connected with the bottom of the pressure ring 4 and connected with the inner pot 3 Keep a distance of 3 to 4mm on the outer surface of the bottom. Since the inner pot 3, the pressure r...

Embodiment 2

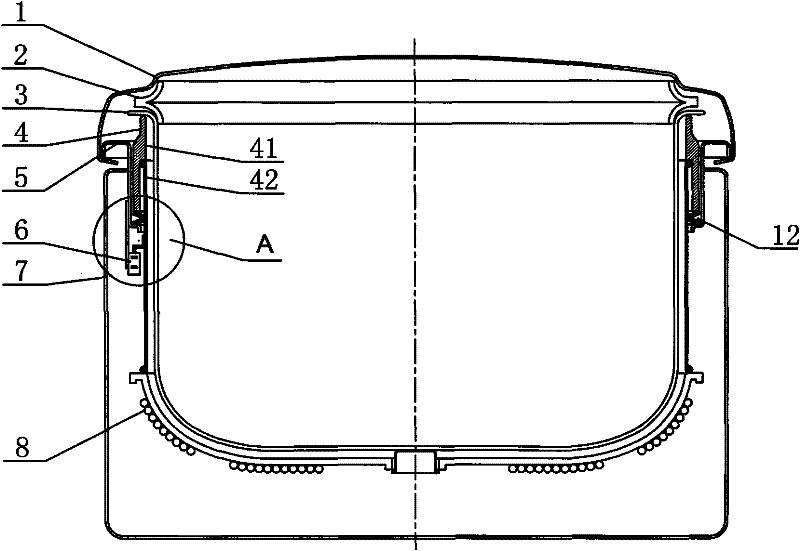

[0029] Embodiment two: as attached figure 2 As shown, compared with Embodiment 1, it is mainly to improve the manufacturability of the pressure ring 4. The difference between this solution and Embodiment 1 is that the pressure ring 4 is fixedly connected by a ring 41 and another annular side wall 42. become. The ring 41 is used to support the inner pot 3 and withstand pressure, and this part is produced by aluminum alloy die-casting; while the lower part of the ring-shaped side wall 42 is connected to the coil disk 8, which is made by sheet metal technology, so that the manufacturing process of the entire pressure ring 4 Can become very easy; The working principle of this embodiment is the same with embodiment one.

Embodiment 3

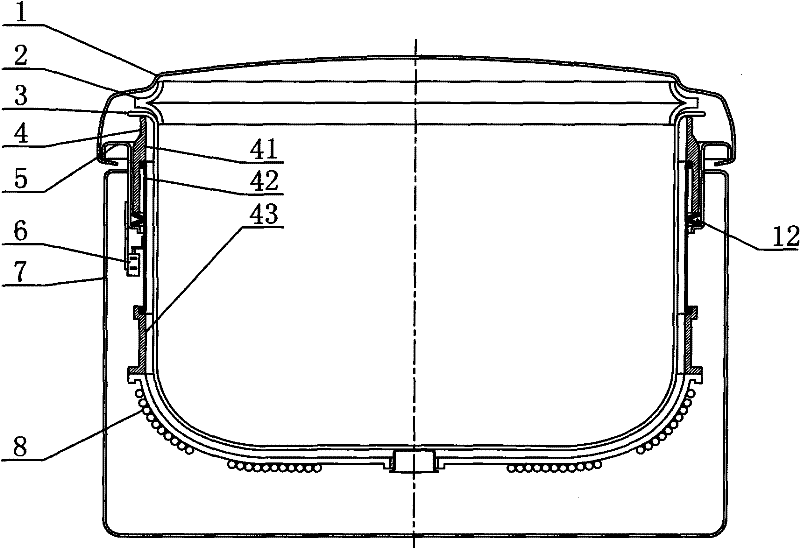

[0030] Embodiment three: as attached image 3 As shown, the difference between the present embodiment and the second embodiment is that the pressure ring 4 is composed of three parts fixedly connected. 8 fixed together. The direct contact piece 43 is made of non-magnetic material, so it will not affect the design and performance of the coil disk 8 . The working principle of this embodiment is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com