Electrolytic polishing cathode for inner hole of deep and long tube

A technology of electrolytic polishing and long tubes, which is applied in the direction of electrolytic process and electrolytic components, which can solve the problems of poor practicability and achieve the effects of good practicability, increased flow, and improved uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

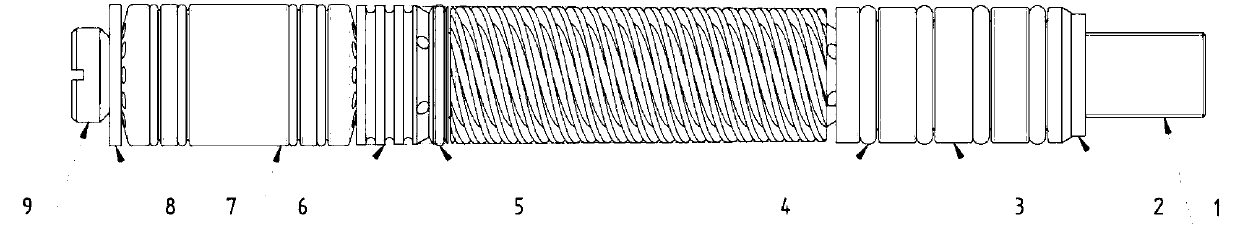

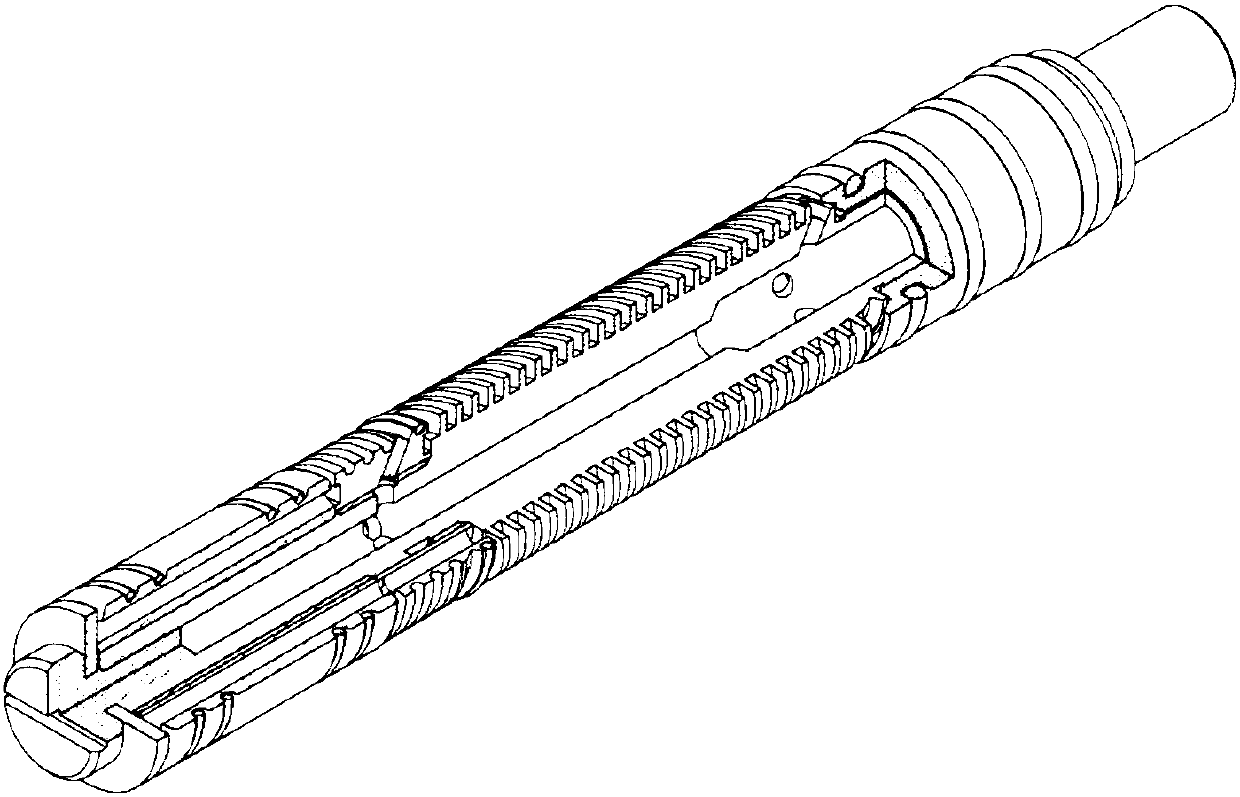

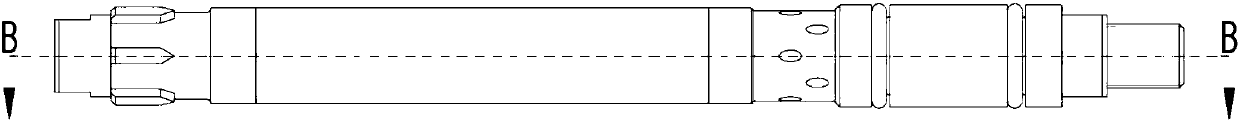

[0012] The following examples refer to Figure 1~2 .

[0013] The electrolytic polishing process cathode of the deep and long tube inner hole of the present invention includes a cathode body 1, a water sealing gasket 2, a front guide 3, a centering O-shaped sealing ring 4, a cathode body ring groove section 5, a shunt O-shaped sealing ring 6, a rear guide 7, Back pressure rubber gasket 8 and screw cap 9. With the cathode body 1 as the central axis, the left end is threaded to connect the cathode body ring groove section 5 and the rear guide 7, put on the back pressure rubber gasket 8, and press it tightly with the screw cap 9; the right end is threaded to connect the front guide 3, and the right end is inserted into the sealing water Gasket 2; there are shunt O-shaped rubber rings 6 and two sets of centering O-shaped sealing rings in the front guide 3, the rear guide 7 and the corresponding ring groove of the cathode body ring groove section. The front guide 3, the rear guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com