Multi-channel dumping grain drying machine

A grain dryer and multi-channel technology, applied in the field of multi-channel discharge grain dryers, can solve the problems of poor grain fluidity, high moisture content and impurity content, affecting drying quality and production efficiency, and achieve uniform grain movement , Reduce the effect of piled up dead area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] specific implementation plan

[0039] Describe the present invention in further detail below with reference to accompanying drawing embodiment

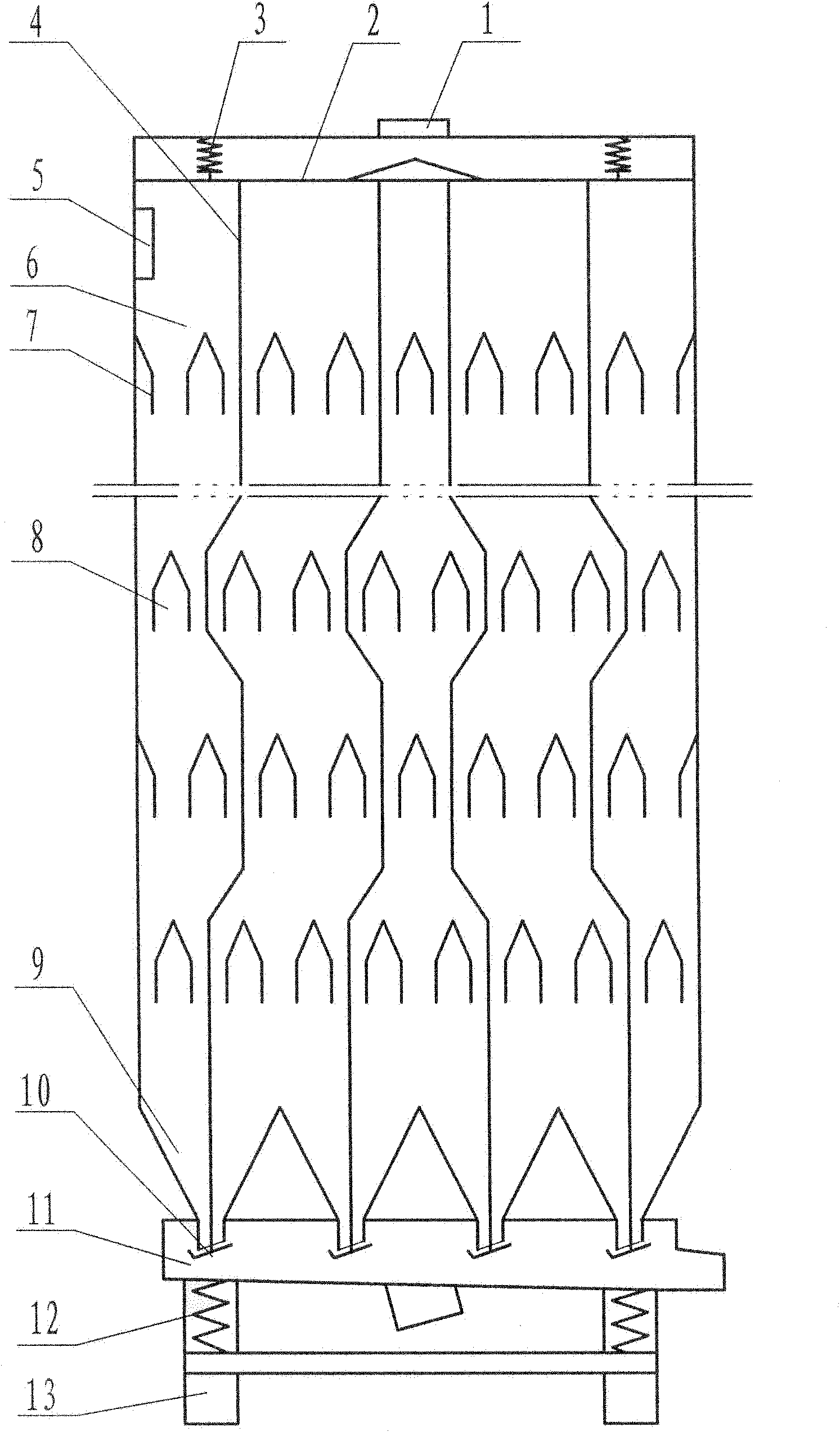

[0040] see Figure 1 to Figure 11 .

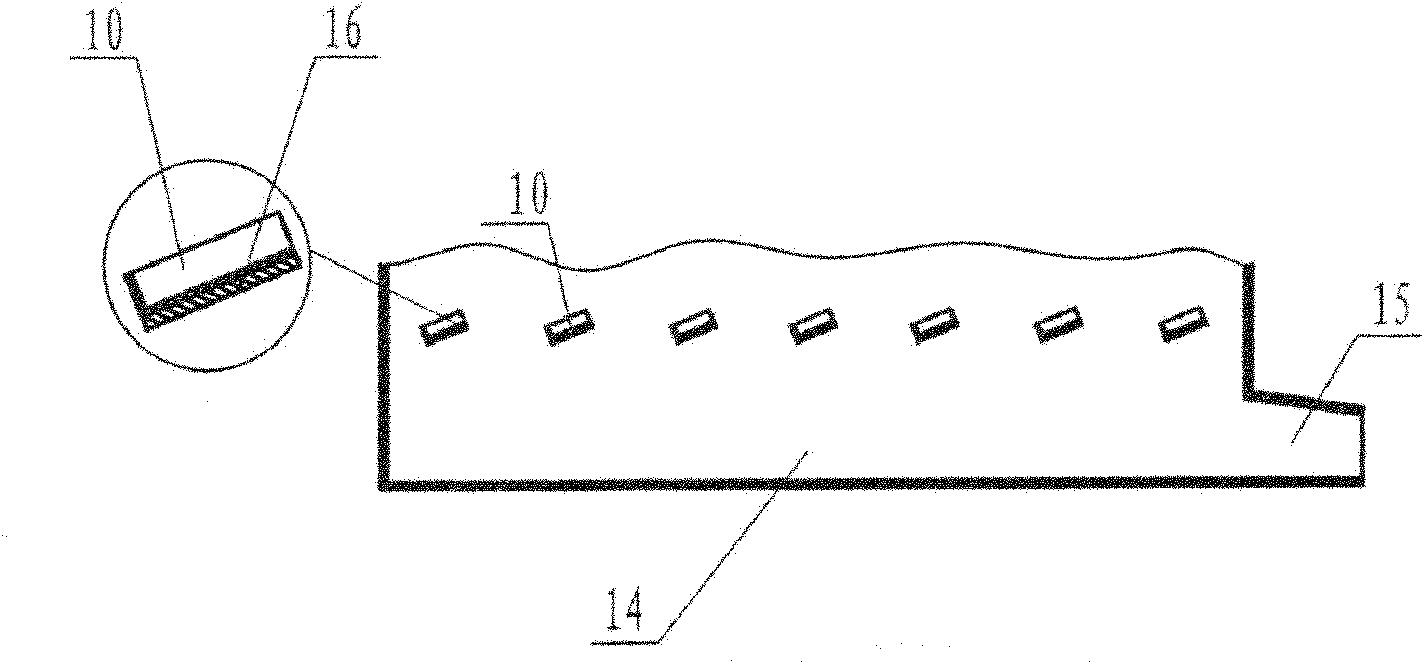

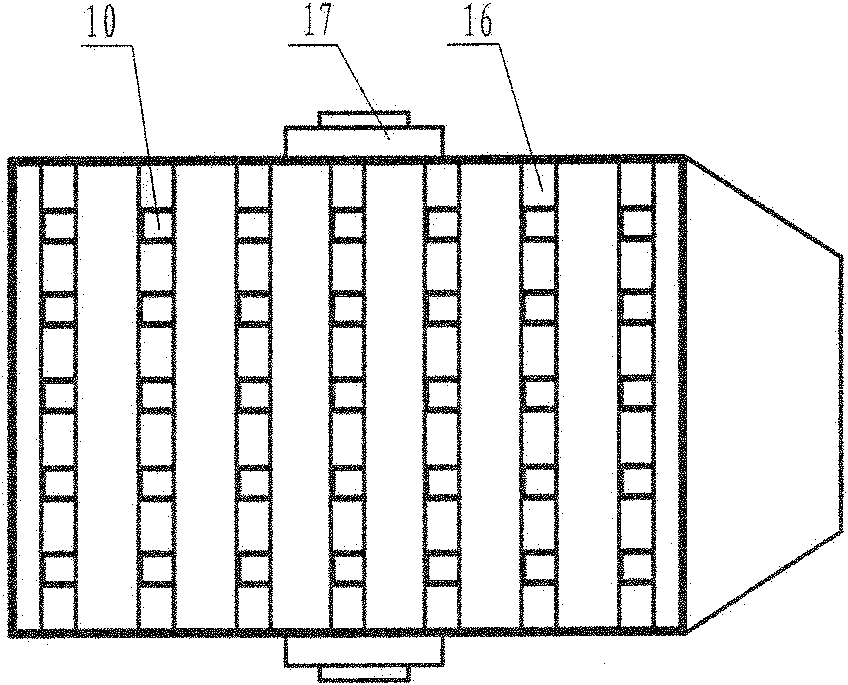

[0041] The lower part of the dryer is a parallel discharge channel (9) composed of a plurality of tetrahedral inverted cones, and the multi-channel discharge mechanism (11) is installed on the elastic support (12); the collection of the multi-channel discharge mechanism (11) The support frame (16) is evenly distributed in the hopper (14), and the installation inclination angle between the support frame (16) and the horizontal plane is between 15° and 25°. A metering block (10) with the same number as the number of discharge channels is installed on the support frame (16), and an interval of 10 to 50 mm is maintained between the metering block (10) and the discharge channel opening (19) of the parallel discharge channel (9); The flat grid (2) on the upper part of the dryer is suspended on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com