Pulse damper using composite spring

A technology of pulsation damper and composite spring, applied in the direction of engine components, machines/engines, liquid fuel feeders, etc., can solve the problem of difficult to control pulsation in a wide pressure range, loss of spring recovery force and spring performance, and difficulty in dealing with spring plasticity Deformation and other problems can be improved to achieve the effect of improving operability, no energy loss, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

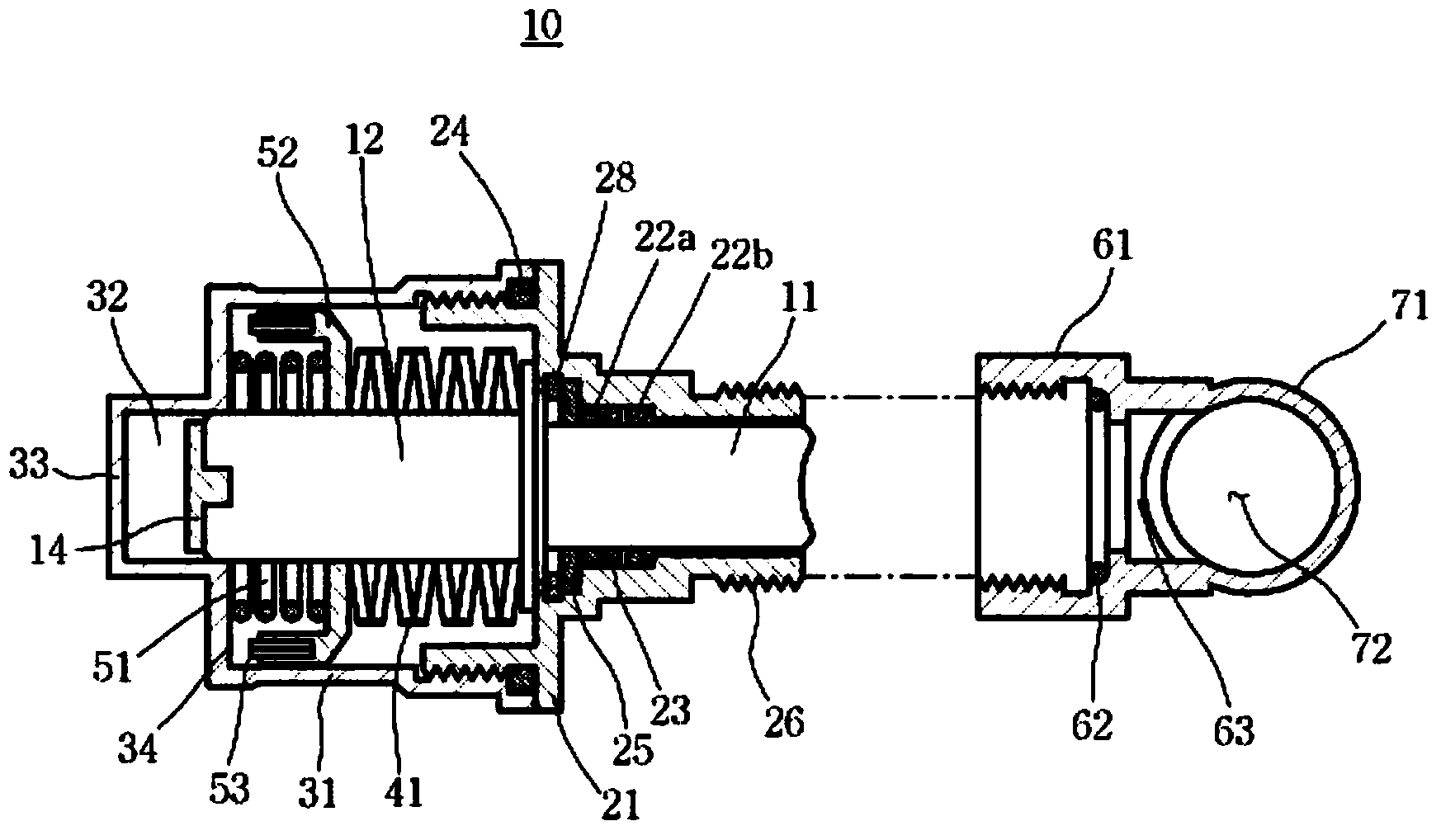

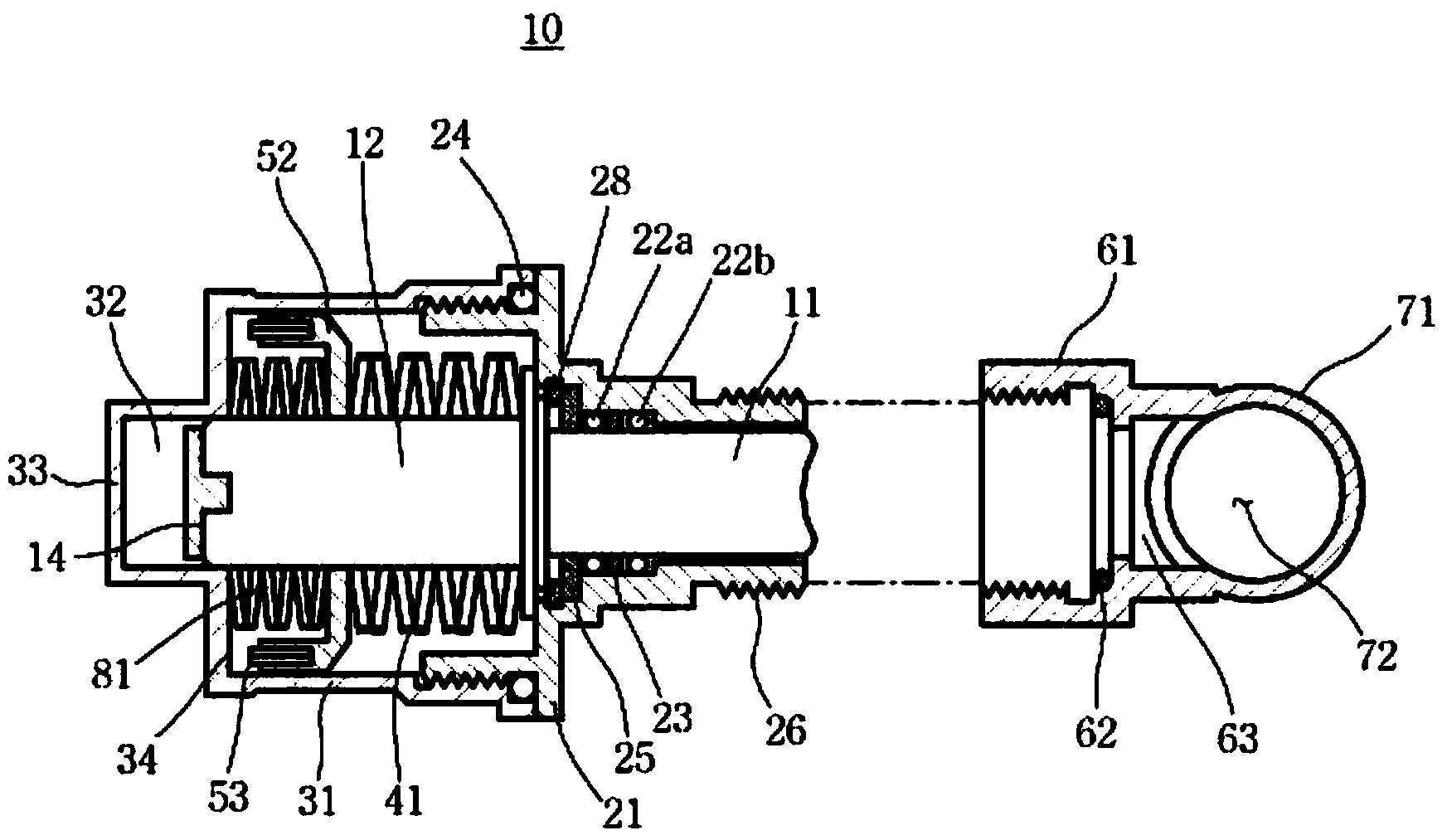

[0027] figure 1 A pulsation damper according to an embodiment of the present invention is shown in a longitudinal sectional view.

[0028] Such as figure 1 As shown, the pulsation damper 10 of the composite spring according to the present invention is composed of a main body 21, a spring body 31, and a connector 61, wherein the main body 21 has a built-in piston 11 capable of rectilinear reciprocating motion, and the spring body 31 and the above-mentioned main body 21 Screwed together, the connector 61 is screwed together with the above-mentioned main body 21 .

[0029] The above-mentioned connector 61 is integrally formed with a fuel rail pipe 71, and the fuel rail pipe 71 is connected to a plunger pump (not shown) for fuel supply of a gasoline direct injection engine, and a connecting passage 63 is formed inside the above-mentioned c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com