Air disc brake

A disc brake and air pressure technology, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of uneven push plate thrust and poor braking stability, and achieve uniform force, stable movement, and avoid The effect of eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

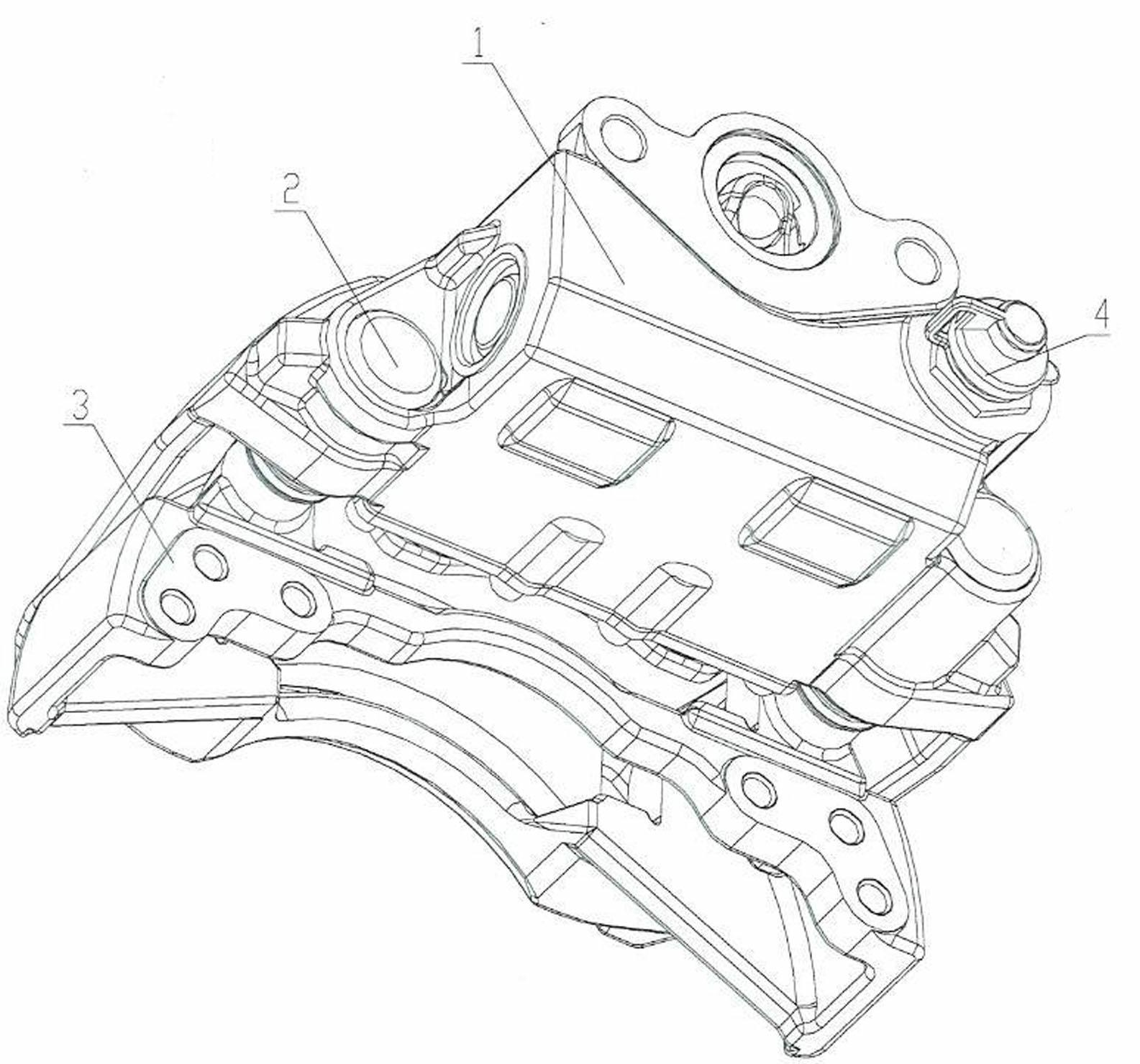

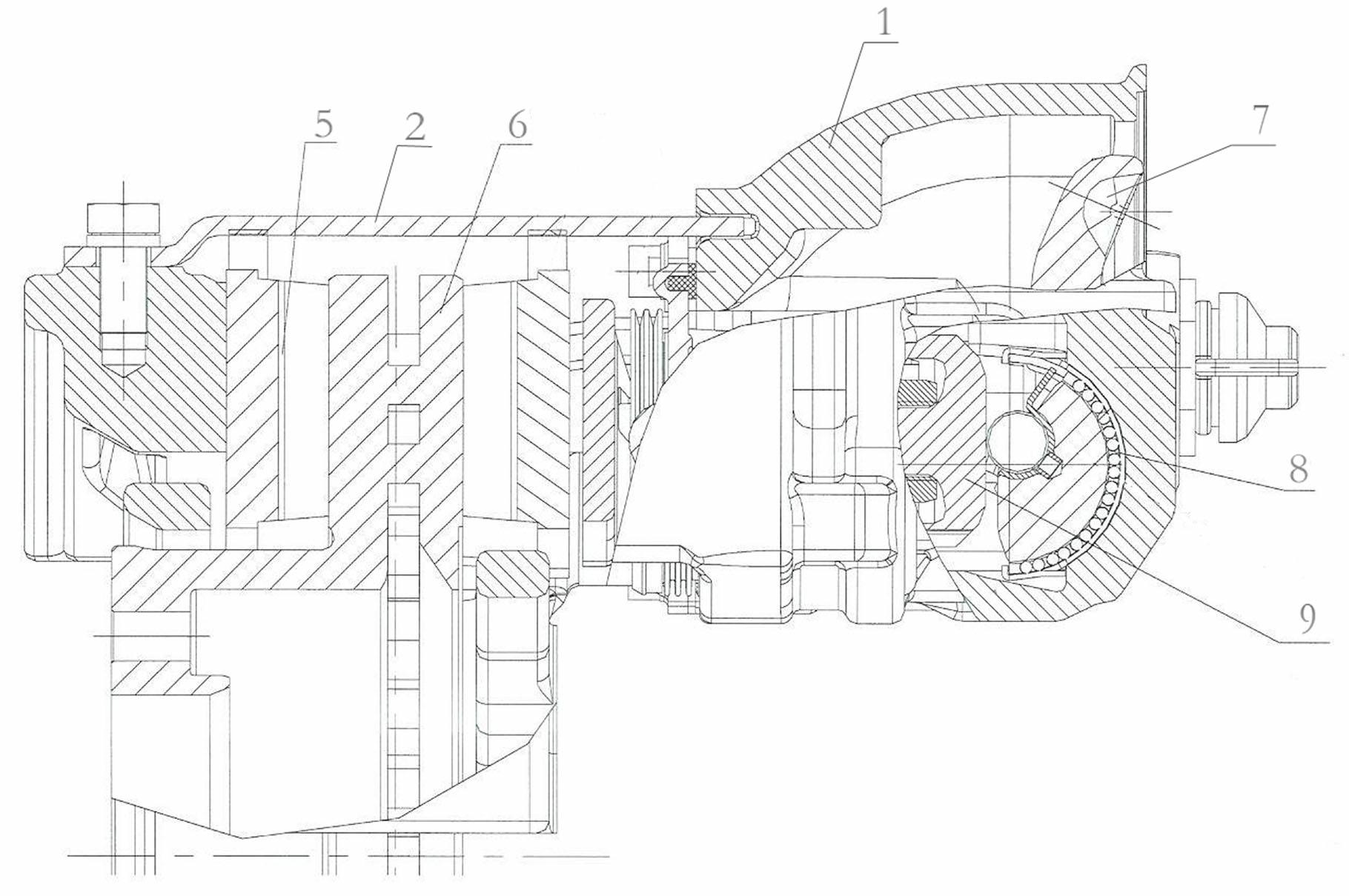

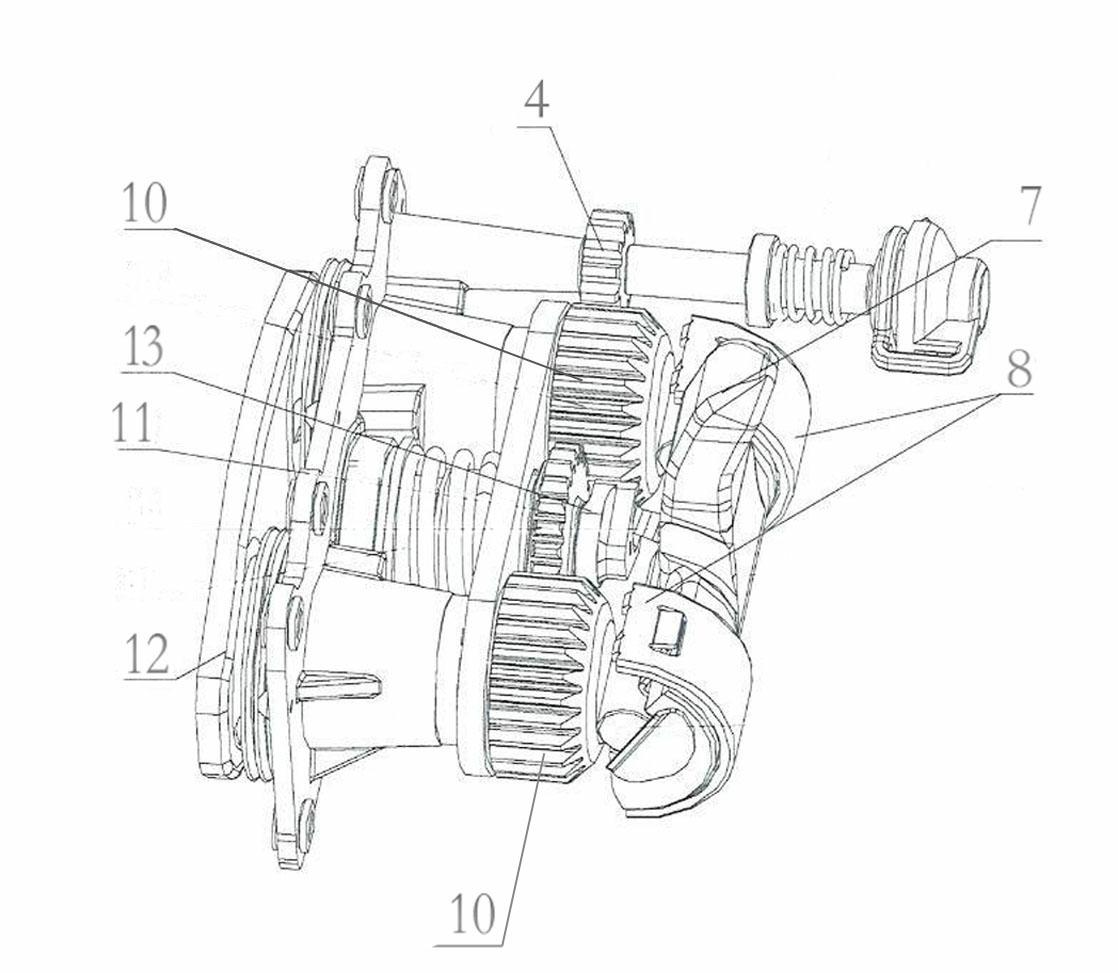

[0022] Such as figure 1 , figure 2 with image 3 A specific embodiment is shown, which includes a bearing system, a booster adjustment system and a friction pair. The boost adjustment system includes a lever system and an adjustment system 9. The adjustment system 9 includes an active adjustment mechanism 13, a driven adjustment mechanism 10, a fixed plate 11, a push plate 12 and a manual adjustment mechanism 4. The fixed plate 11 is fixed on the caliper body by bolts 19. 1, the active adjustment mechanism 13, the driven adjustment mechanism 10 and the manual adjustment mechanism 4 are arranged on the fixed plate 11, and the fixed plate 11 is provided with two piston brackets for setting the driven adjustment mechanism 10, and the driven adjustment mechanism 10 There are two, respectively arranged in the two piston brackets, the two driven adjustment mechanisms 10 are located on both sides of the active adjustment mechanism 13, each of the two driven adjustment mechanisms 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com