Double-membrane back pressure valve

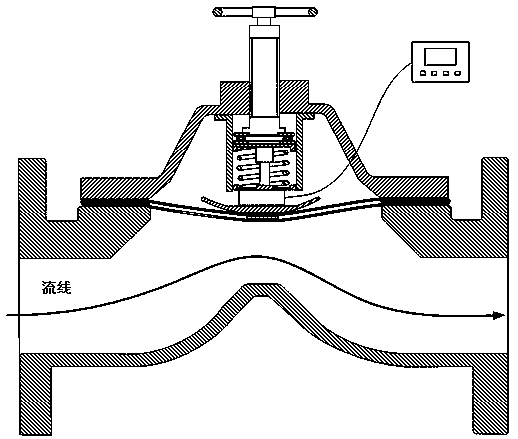

A back pressure valve, double diaphragm technology, applied in the direction of diaphragm valve, diaphragm, valve device, etc., can solve the problems of large flow loss and many turns of the back pressure valve flow passage, achieve small flow resistance, avoid violent oscillation of the spring, reduce The effect of small perturbations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

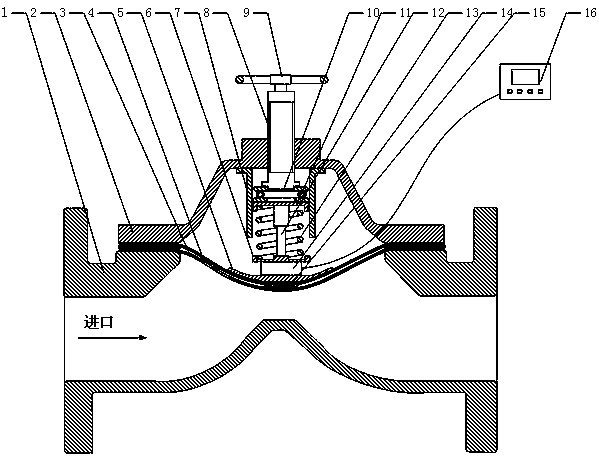

[0023] The present invention will be further described below by means of the accompanying drawings.

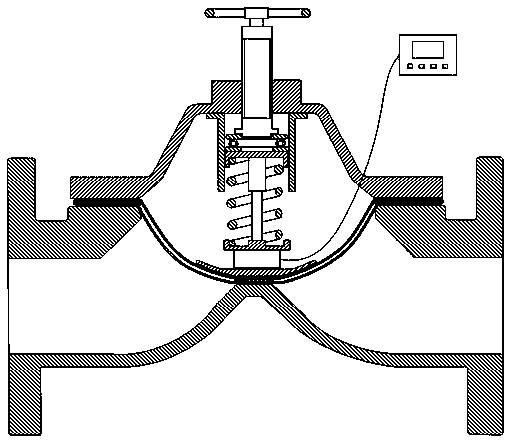

[0024] Such as figure 1 As shown, the double diaphragm back pressure valve of the present invention consists of valve body 1, valve cover 2, lower diaphragm 3, upper diaphragm 4, bottom plate 5, lower spring seat 6, sleeve 7, valve stem 8, hand wheel 9, thrust The bearing 10, the upper spring seat 11, the damper 12, the spring 13, the load cell 14, the metal support piece 15, and the display unit 16 are composed. The lower diaphragm 3 and the upper diaphragm 4 are separated by a metal support plate 15 to form an intermediate cavity, and the spring 13 and the damper 12 are fixed on the upper diaphragm 4 through the upper spring seat 11, the lower spring seat 6 and the bottom plate 5, and the upstream of the lower diaphragm 3 There is a small hole in the position. A damper 12 is installed between the upper and lower spring seats. The load cell 14 is installed between the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com