Supercritical water oxidation reactor

A technology of supercritical water oxidation and reactors, applied in chemical/physical/physicochemical nozzle reactors, processes under supercritical conditions, chemical instruments and methods, etc., can solve corrosion and salt deposition, reactors Overheating, uneven distribution of evaporated water, etc., to achieve uniform distribution, good protection, and avoid inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

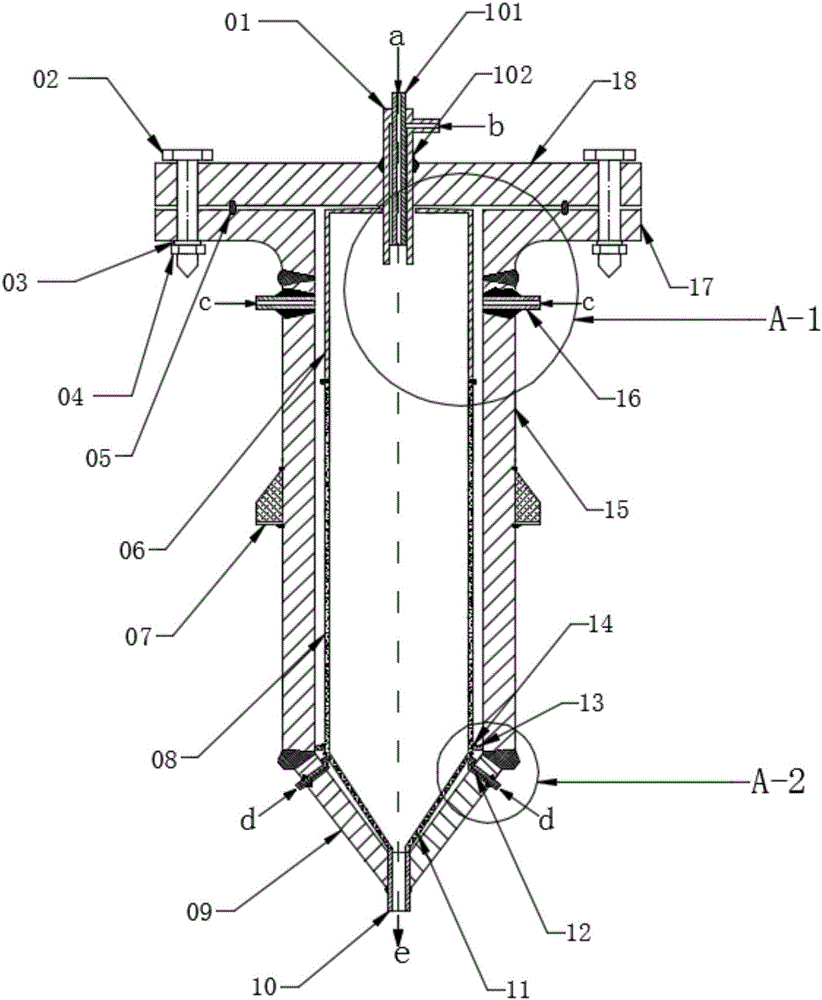

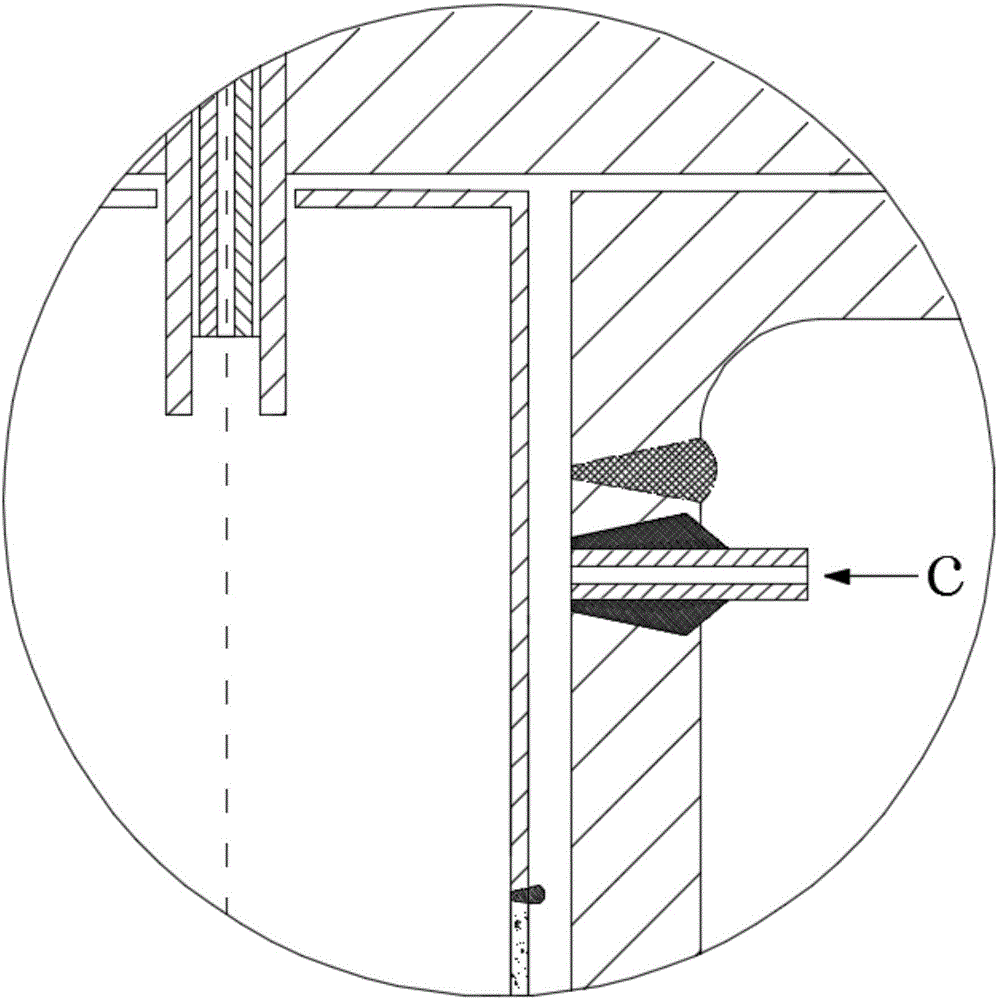

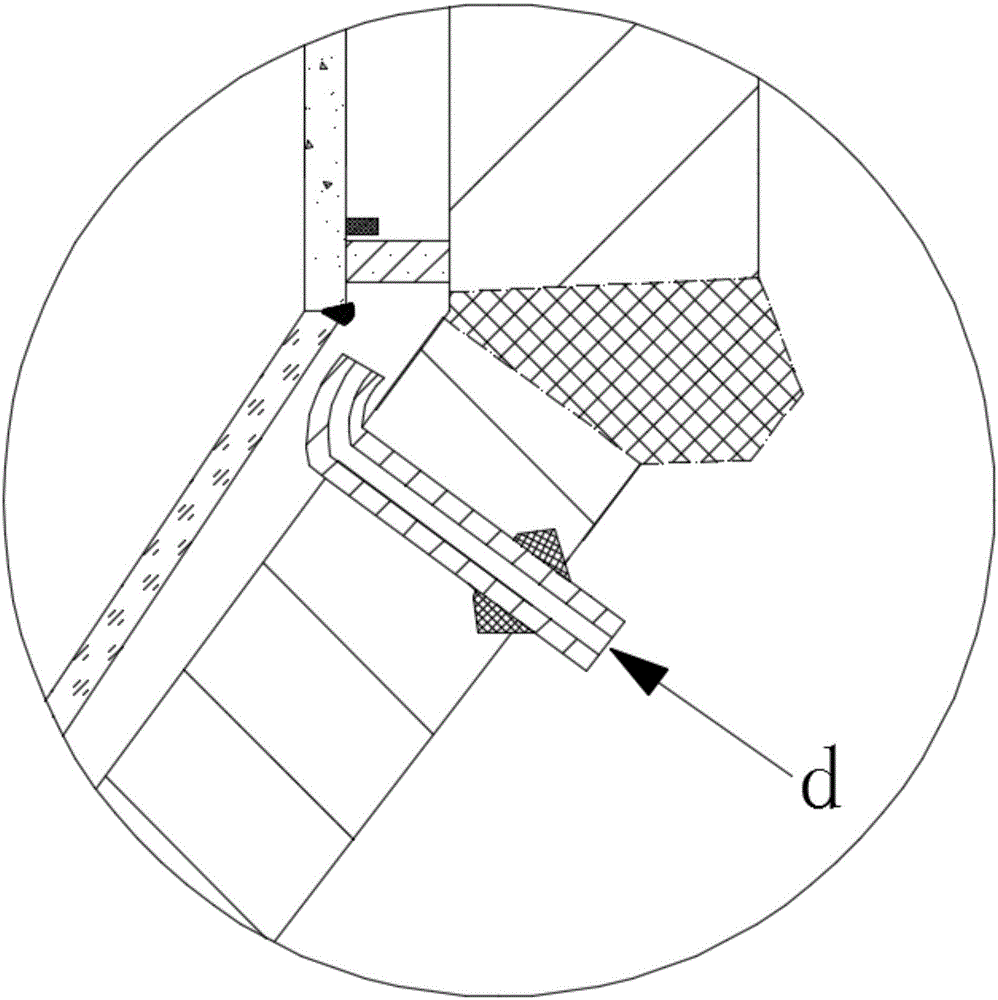

[0032] Such as Figure 1-Figure 3 As shown, the supercritical water oxidation reactor of the present invention includes a double-shell structure of an inner shell and an outer shell, wherein the inner shell serves as a temperature-bearing component and the outer shell serves as a pressure-bearing component, that is, the inner shell can withstand high temperature, corrosion, and salt deposition without Withstand pressure, while the shell is under pressure without being subjected to high temperatures. In this way, the shell does not need to select high-temperature and corrosion-resistant materials, thereby significantly reducing the cost of the reactor.

[0033] The inner shell is coaxially arranged inside the outer shell; the inner shell is divided into a hollow upper cylinder and a lower cone; the cylinder includes an upper non-porous pipe 06 and a lower straight porous pipe 08; the cone is a cone Shaped porous wall 11;

[0034] The shell is composed of an upper connecting flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com