Screw thread welding integral narrow slit type cold junction for coaxial pulse-tube refrigerator

A pulse tube refrigerator and slit technology, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problems of poor laminar fluidization effect, reduce the empty volume of the cold end and ensure reliability. , the effect of ensuring reliability and safety of leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation modes and specific operating procedures are given, but the scope of protection of the present invention is not limited to the following Mentioned examples.

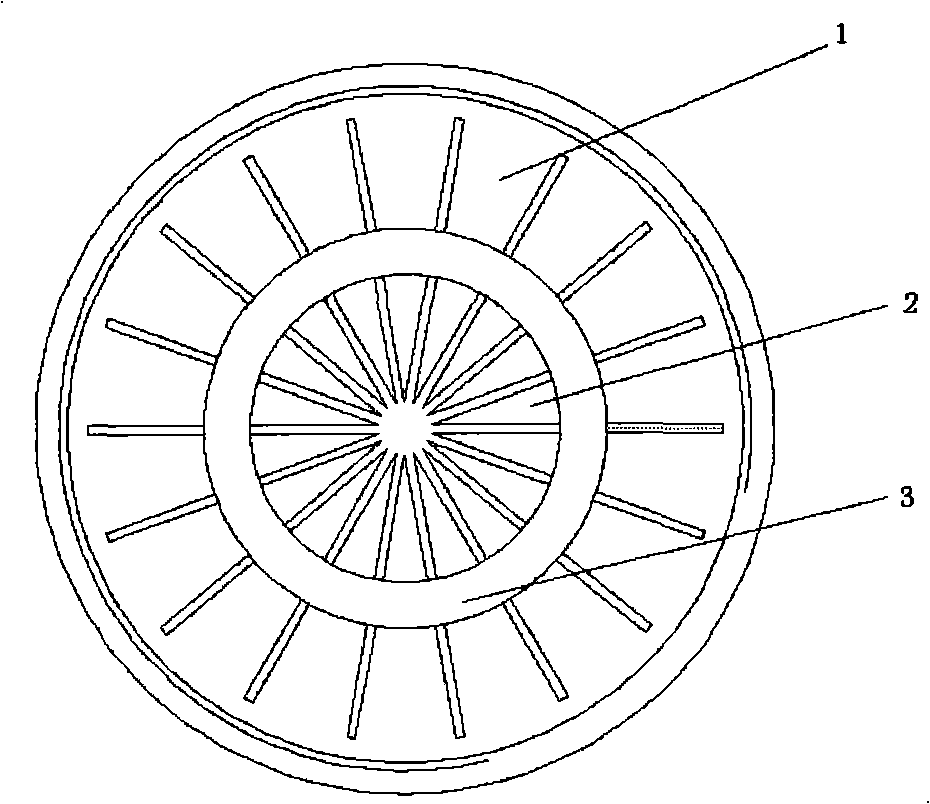

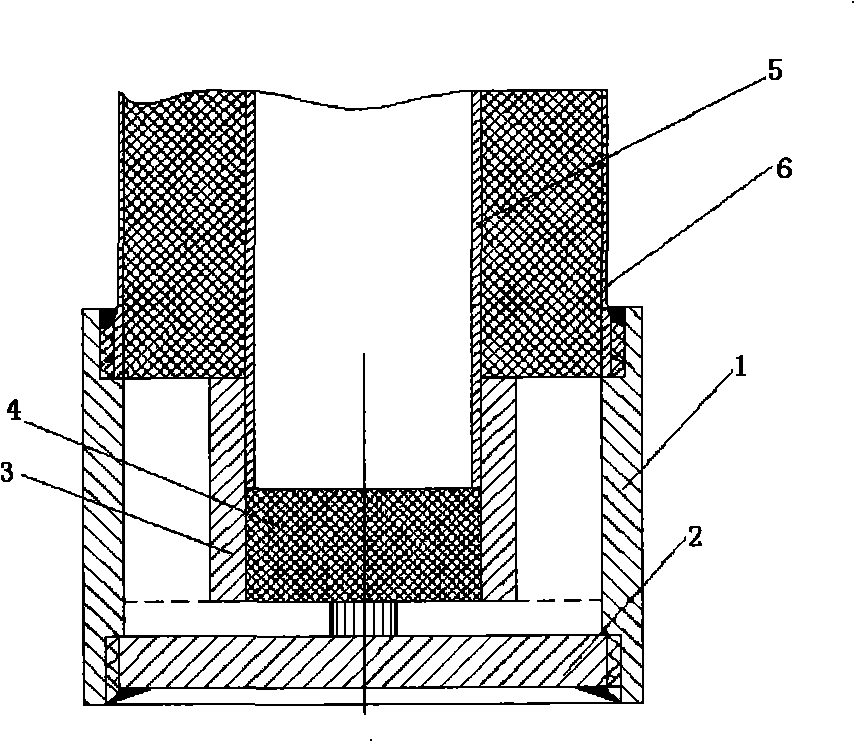

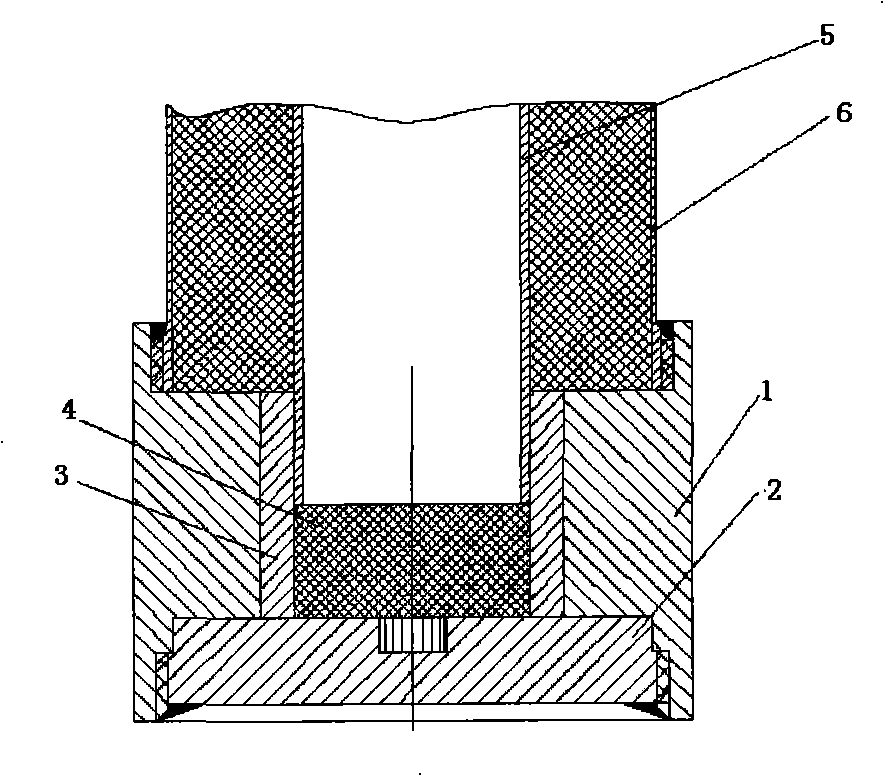

[0030] As shown in the figure, the present invention includes four parts: the upper cold head 1, the lower cold head 2, the cold end baffle 3 and the laminated red copper wire mesh 4. The upper cold head 1 has internal threads at both ends, one end is connected with the external thread of the lower cold head 2 and then welded, and the other end is threaded to the end of the cold accumulator 6 and then welded; the upper cold head 1 has a round hole in the center, and the round hole is open around it There are uniformly distributed radial slits, and the cold end baffle 3 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com