Method of hydraulic fracture of subterranean formation

An underground formation and fracturing fluid technology, which is applied in the field of hydraulic fracturing to achieve the effects of improving the effective conductivity, increasing the effective half-length of cracks, and improving the stimulation of oil wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

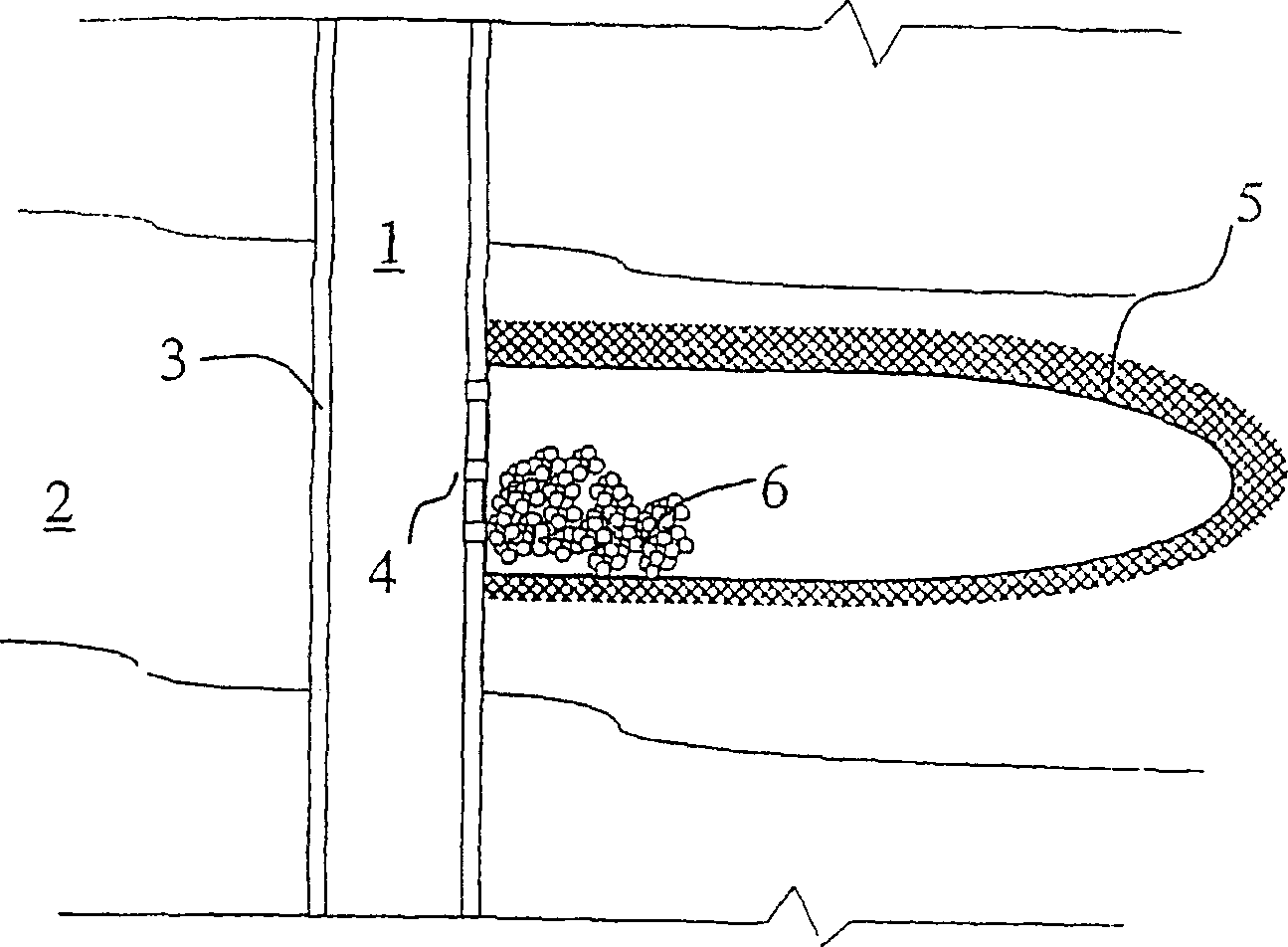

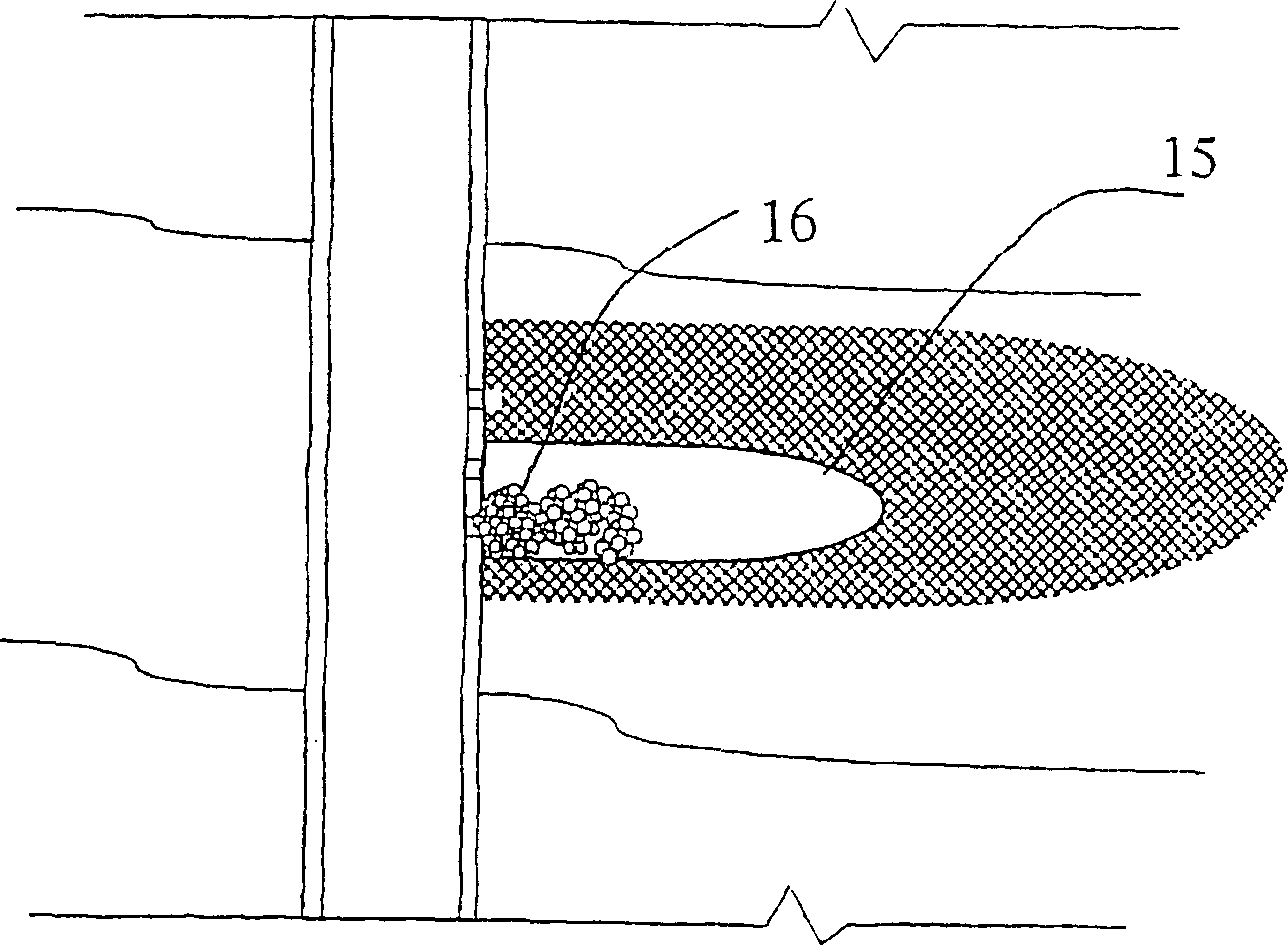

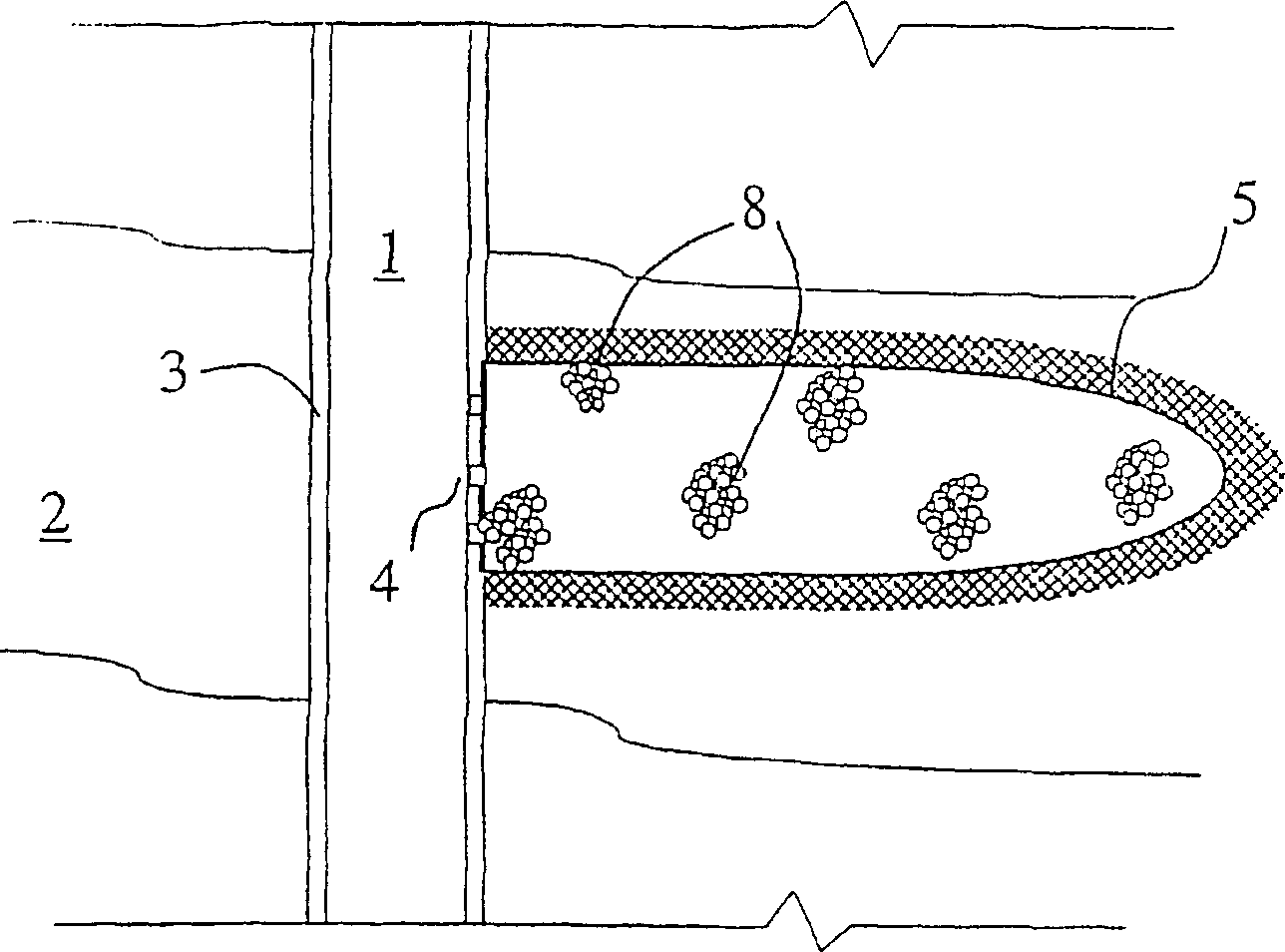

[0036] In many cases, the hydraulic fracturing treatment consists in pumping a proppant-free viscous fluid, or pad (typically, water and some fluid additive that creates a high viscosity) into the well faster than the fluid can enter the formation, so the pressure Rise and fracture the rock, creating artificial fractures and / or widening existing fractures. A proppant such as sand is then added to the fluid to form a mortar that is pumped into the fracture to prevent the fracture from closing when the pumping pressure is released. The proppant transport capability of the base fluid depends on the type of viscosifying additive added to the aqueous matrix.

[0037] Water-based fracturing fluids to which water-soluble polymers have been added to prepare viscosified solutions are widely used in the field of fracturing. Since the late 1950s, more than half of all fracking treatments have been performed with fluids that include guar gum, high molecular weight polysaccharides compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com