A method for fermenting bio-organic fertilizer by using domestic excrement and straw

A technology for fermenting organisms and excreta, which is applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of inconvenient transportation and application of non-dry fertilizers, poor soil improvement effect, and low straw utilization, and achieve convenient transportation and Effects of application, increase of growth and yield, increase of grain yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

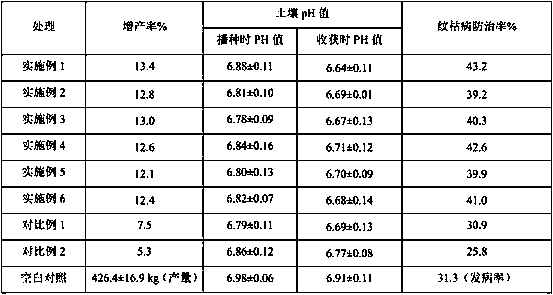

Examples

Embodiment 1

[0035] (1) The magnesium sulfate solution with a mass ratio concentration of 4% and the ferrous sulfate solution with a mass ratio concentration of 25% are mixed at a volume ratio of 1:1 to obtain a sulfate mixture; mix the sulfate mixture with residential excrement Mix according to the volume-to-mass ratio of 4L:1000Kg, stir evenly, and place at room temperature for 3 days to obtain excrement degradation material;

[0036] (2) Mix corn stalks and reed stalks at a weight ratio of 1:3, and pulverize them to 0.5 cm; mix the crushed straw mixture with the excrement degradation material at a ratio of 2:1 to obtain fermentation raw materials;

[0037] (3) Inoculate the decomposed mixed bacteria in the fermented raw material according to the inoculation amount of 2% of the weight of the fermented raw material, adjust the water content to 55%, and under the condition of heat preservation, compost and ferment for 20 days at 55°C to obtain the decomposed material; wherein the decomposed...

Embodiment 2

[0042] (1) The magnesium sulfate solution with a mass ratio concentration of 4% and the ferrous sulfate solution with a mass ratio concentration of 25% are mixed at a volume ratio of 1:1 to obtain a sulfate mixture; mix the sulfate mixture with residential excrement Mix according to the volume-to-mass ratio of 4L:1000Kg, stir evenly, and place at room temperature for 4 days to obtain excrement degradation material;

[0043] (2) Mix corn stalks and reed stalks at a weight ratio of 1:2, and pulverize them to 0.8 cm; mix the crushed straw mixture with the excrement degradation material at a ratio of 3.5:1 to obtain fermentation raw materials;

[0044] (3) Inoculate the decomposed mixed bacteria in the fermented raw material according to the inoculum amount of 3% of the weight of the fermented raw material, sprinkle water to adjust the water content to 60%, and under the condition of heat preservation, compost and ferment for 25 days at 40°C to obtain the decomposed material; the d...

Embodiment 3

[0049] (1) The magnesium sulfate solution with a mass ratio concentration of 4% and the ferrous sulfate solution with a mass ratio concentration of 25% are mixed at a volume ratio of 1:1 to obtain a sulfate mixture; mix the sulfate mixture with residential excrement Mix according to the volume-to-mass ratio of 5L:1000Kg, stir evenly, and place at room temperature for 5 days to obtain excrement degradation material;

[0050] (2) Mix corn stalks and reed stalks at a weight ratio of 1:2.5, and pulverize them to 1.0 cm; mix the pulverized straw mixture with the excrement degraded material at a ratio of 4.5:1 to obtain fermentation raw materials;

[0051] (3) Inoculate the decomposed mixed bacteria in the fermented raw material according to the inoculation amount of 0.5% of the weight of the fermented raw material, sprinkle water to adjust the water content to 58%, and under the condition of heat preservation, compost and ferment for 10 days at 65°C to obtain the decomposed clinker;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com