Superconducting wire joint

A superconducting wire and superconducting technology, applied in the direction of conductive connections, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of low critical performance of superconducting wire joints, complex and harsh process atmosphere conditions, non-superconducting joints, etc. problem, to achieve the effect of improving the cooling effect, stabilizing the critical performance, and simplifying the experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

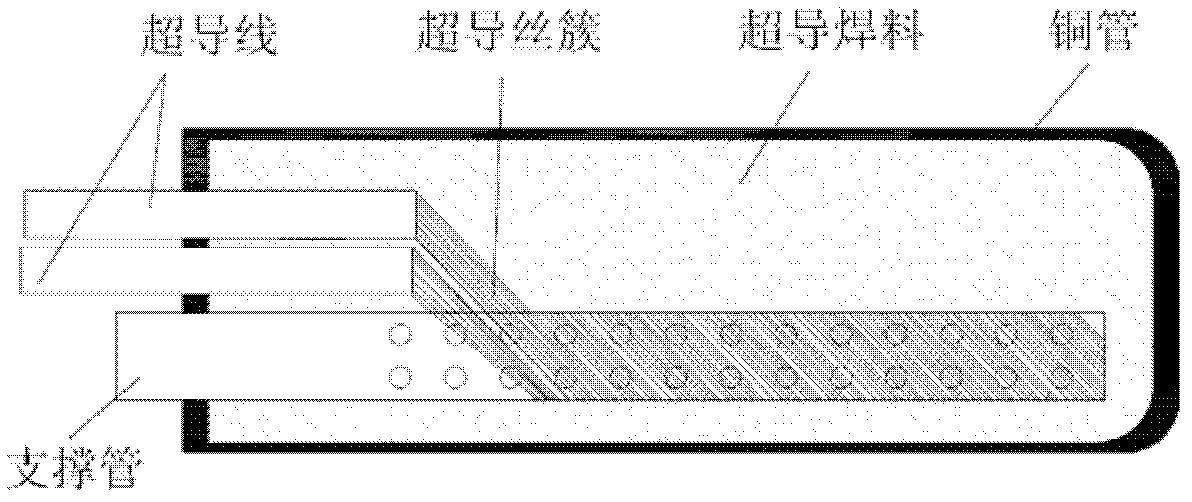

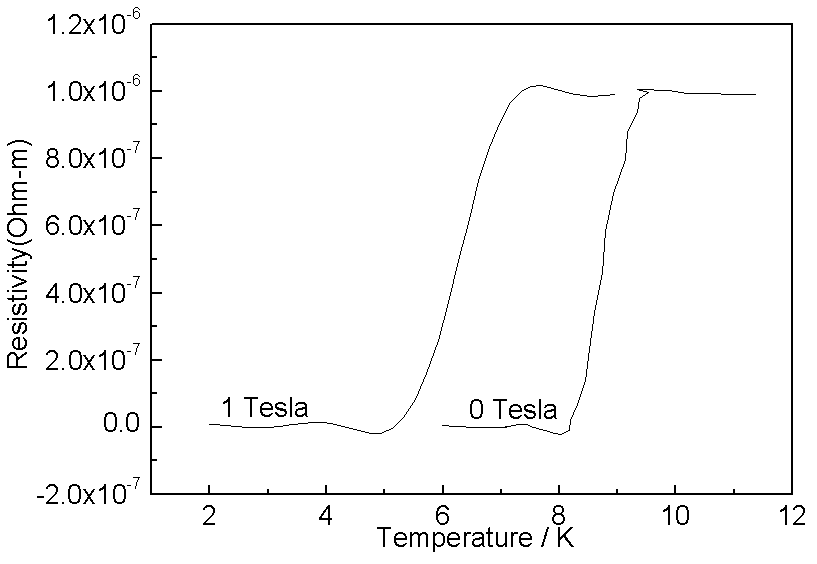

[0037] Prepare NbTi / Cu superconducting wire joints. The superconducting wires to be connected are two NbTi / Cu superconducting wires of the same specification, the cross-section of the superconducting wire is round, the wire diameter is 0.65mm, the copper superconductivity is 2, the average wire diameter of the superconducting wire is 13μm, the number of wires is 830, and the minimum residual resistivity 100. The preparation method of the superconducting wire joint adopting the present invention is as follows: firstly, the insulating layer outside the superconducting wire to be connected is removed; the superconducting wire is immersed in the precursor solder melt until the pure copper or copper at the end of the superconducting wire is removed. The alloy matrix materials are all corroded, exposing scattered superconducting wire clusters; the components of the precursor solder are Sn and Pb, and the mass ratio of each component is Sn: 85%, and the balance is Pb; The guide wire ...

Embodiment 2

[0041] In the preparation of Nb 3 In the process of Sn superconducting coil, NbTi / CuNi superconducting wire and Nb 3 Sn / Cu superconducting wire connector. Among them, NbTi / CuNi superconducting wire is used for superconducting switch, and Nb 3 Sn / Cu superconducting wire is Nb 3 Wire for Sn superconducting coil. Nb 3 The Sn superconducting magnet is connected to the superconducting switch through a superconducting wire connector to realize closed-loop operation.

[0042] During the preparation of the superconducting wire joint, the superconducting wires to be connected are two superconducting wires of different specifications. Among them, the cross-section of the NbTi / CuNi superconducting wire is circular, the wire diameter is 0.50mm, the copper ratio is 1.35, the number of superconducting wires is 54, the minimum residual resistivity is 70, and the base material is CuNi alloy. Nb 3 The specifications of Sn / Cu superconducting wire are: circular cross section, wire diameter 0.90mm,...

Embodiment 3

[0045] The joint of NbTi / CuNi superconducting wire and NbTi / Cu superconducting wire is prepared, and the superconducting wires to be connected are two superconducting wires of different specifications. Among them, the cross-section of the NbTi / CuNi superconducting wire is circular, the wire diameter is 0.50mm, the copper ratio is 1.35, the number of superconducting wires is 54, the minimum residual resistivity is 70, and the base material is CuNi alloy. The cross-section of the NbTi / Cu superconducting wire is circular, the wire diameter is 0.85mm, the copper ratio is 1.3, the number of superconducting wires is 54, the minimum residual resistivity is 70, and the base material is pure Cu. The preparation method of the superconducting wire joint adopting the present invention is as follows: first remove the formvar material insulating layer outside the NbTi / CuNi superconducting wire and the NbTi / Cu superconducting wire; then immerse the superconducting wire to be connected into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com