Abnormal-shape filament non-woven fabric and manufacture technology thereof

A non-woven, special-shaped fiber technology, used in textiles and papermaking, fiber processing, non-woven fabrics, etc., can solve problems such as increasing transportation and personnel costs, harming baby's delicate skin, affecting softness and fluffy, etc. The effect of saving technical transformation costs, saving labor and product costs, and reducing transportation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

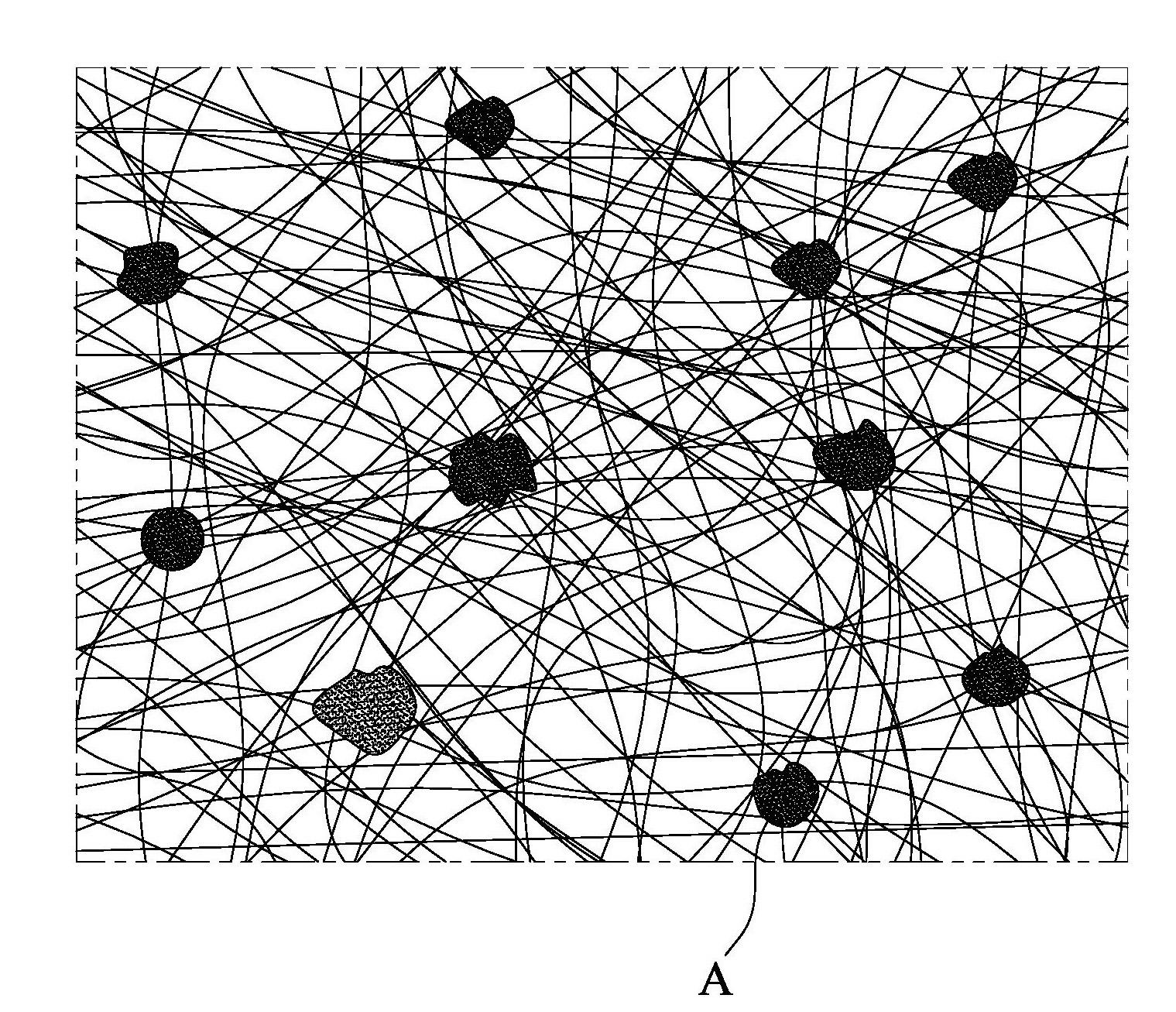

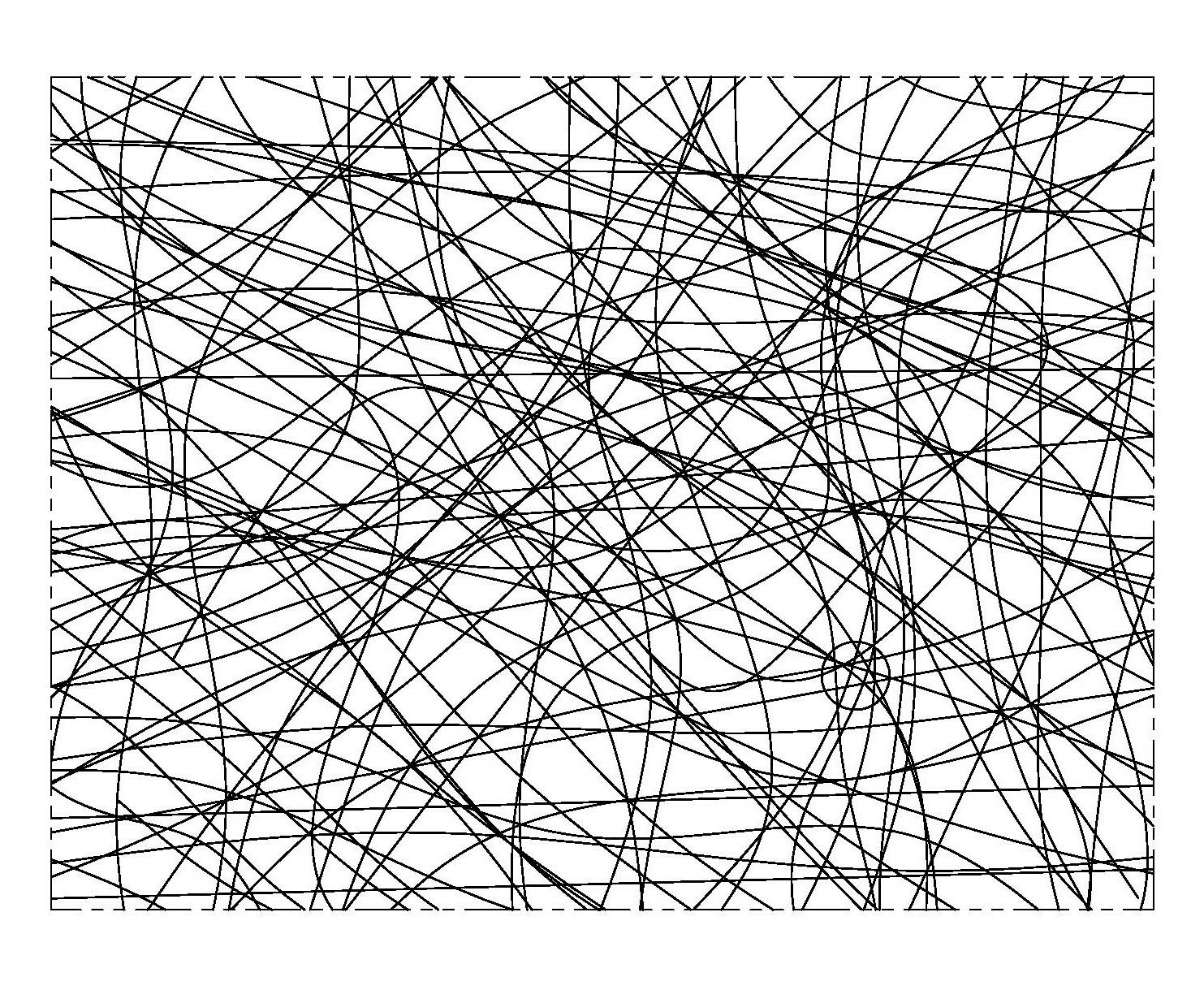

[0033] Example 1 adopts PE and PET raw materials, is extruded by a twin-screw extruder, and forms a skin-core structure through a spinneret. 2.5 special-shaped long fiber, after laying the net, it is formed by hot air in an oven, and finally cut and wound online to form a coil. The temperature of the hot air box is 138°C, and the weight of the product is 24g / m 2 Long fiber non-woven fabric.

[0034] Fiber specific surface area

[0035] The specific surface of the fiber is equal to the total surface area of the fiber per unit mass.

[0036] For fibers with a circular cross-section,

[0037]

[0038] where, ρ = fiber density

[0039] Dpf(d / f) = denier of a single fiber

[0040] L=length, 9×10 5 cm

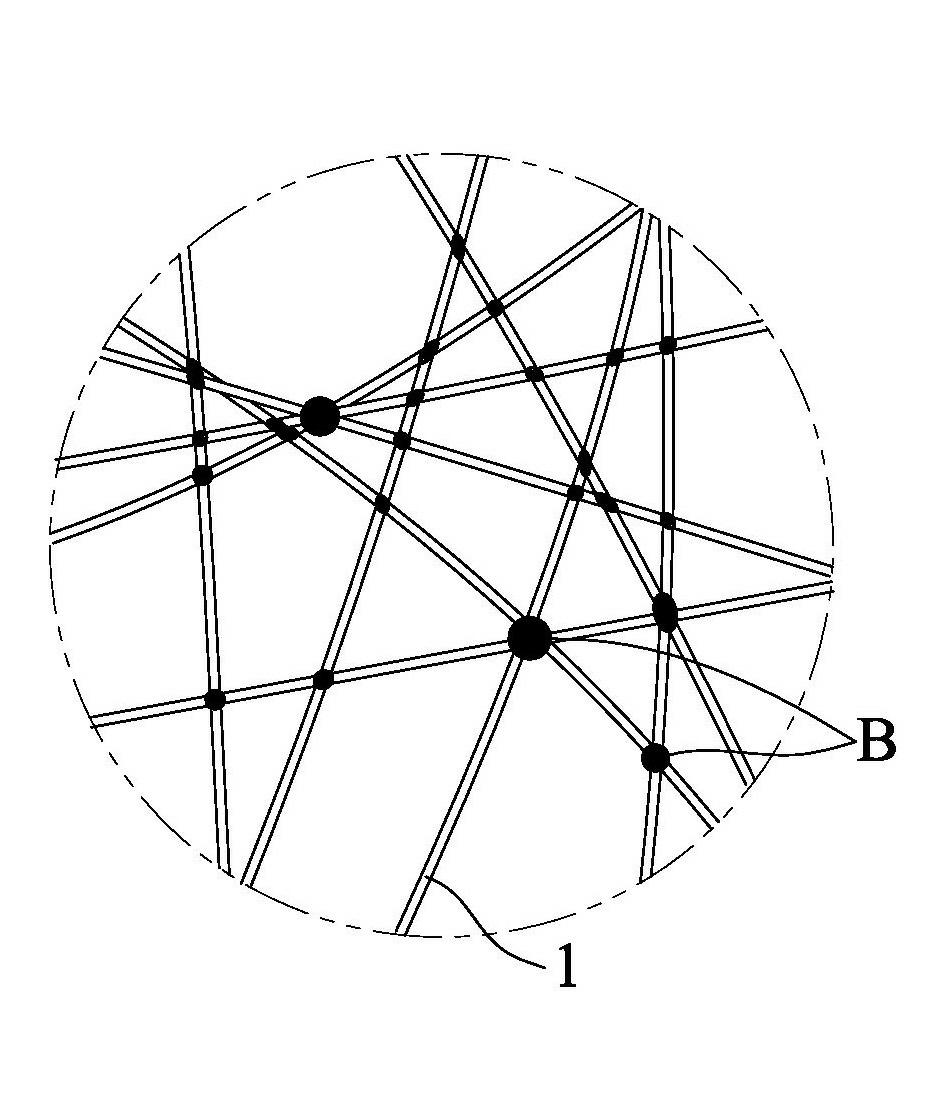

[0041]For special-shaped fibers, the specific surface area is equal to the specific surface area of the same material and the same denier circular cross-section fiber × shape coefficient α, and the shape coefficient α refers to the cross-sectional circumference of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com