Fracturing propping agent and its preparation method

A technology of fracturing proppant and silane coupling agent, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc. It can solve the problems of poor flow conductivity, high breakage rate of ceramsite and quartz sand, and easy occurrence of ceramsite Migration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

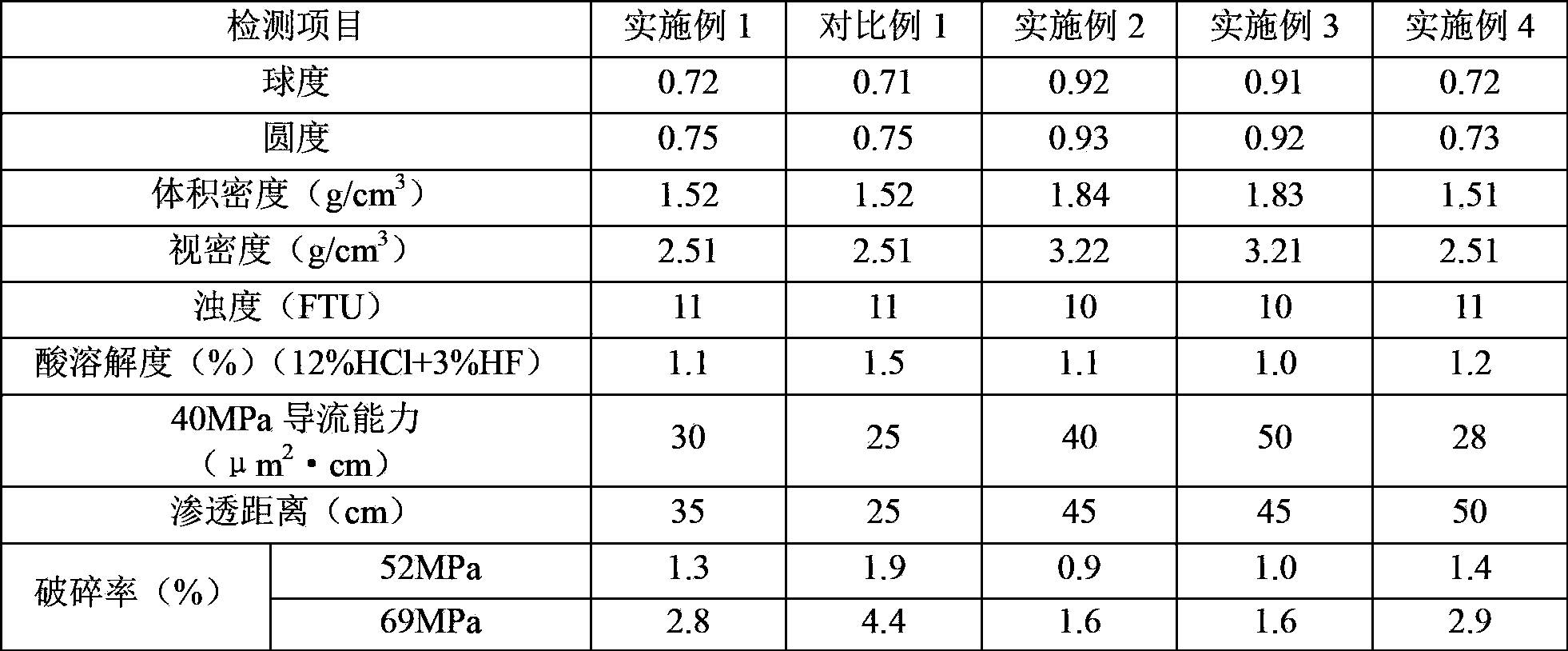

Examples

preparation example Construction

[0023] The preparation method of the fracturing proppant provided by the present invention comprises uniformly mixing aggregate particles and a silane coupling agent and reacting to obtain aggregate particles whose surface is coated with a silane coupling agent layer, and coating the surface The aggregate particles with the silane coupling agent layer are mixed evenly with the resin and cured.

[0024] In the present invention, the conditions for reacting the mixture of aggregate particles and silane coupling agent are not particularly limited, as long as the obtained aggregate particles can be coated with a layer of silane coupling agent on the surface, generally speaking, the The reaction conditions include reaction temperature and reaction time. The reaction temperature can be selected and changed within a wide range, but in order to be more conducive to the firm combination between the silane coupling agent layer and the aggregate particles, the reaction temperature is pre...

Embodiment 1

[0038] This example is used to illustrate the fracturing proppant provided by the present invention and its preparation method.

[0039] (1) Mix 2000g of raw sand and 2g of r-aminopropyltriethoxysilane evenly, then raise the temperature to 250°C and stir for 0.05 hours to obtain aggregate particles coated with a silane coupling agent layer ;

[0040] (2) At 250°C, mix the aggregate particles coated with a silane coupling agent layer obtained in step (1) with 100 g of epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-44, The epoxy value is 0.44mol / 100g, the hydroxyl value is 0.088mol / 100g) Stir and mix evenly, then add 40g tetrahydrophthalic anhydride and 3g diethylenetriamine and continue to stir and mix for 0.05 hours, then lower the temperature to room temperature 25°C, thus A fracturing proppant Z1 comprising a silane coupling agent layer and a resin layer coated sequentially on the surface of aggregate particles is obtained, wherein th...

Embodiment 2

[0042] This example is used to illustrate the fracturing proppant provided by the present invention and its preparation method.

[0043] (1) Mix 2000g of ceramsite with 2g of N-(β-aminoethyl)-r-aminopropylmethyldimethoxysilane evenly, then raise the temperature to 100°C and stir for 0.5 hours to obtain a surface Aggregate particles coated with a silane coupling agent layer;

[0044] (2) At 100°C, mix the aggregate particles coated with a silane coupling agent layer obtained in step (1) with 100 g of polyurethane resin (commercially purchased from Dongguan Jingze Resin Co., Ltd., brand name FR-HE603) Stir and mix evenly, then add 10g of TDI trimer curing agent (Bogao Paint Factory, Leliu Town, Shunde City, BG350TB) and continue to stir and mix for 0.5 hours, then lower the temperature to room temperature 25°C, so as to obtain The fracturing proppant Z2 of the silane coupling agent layer on the particle surface and the resin layer, wherein the thickness of the silane coupling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com