Valve rod

A valve stem and rod body technology, applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems of high flatness processing requirements, affecting sliding stability, shortening the life of valve stems, etc., to improve contact tightness and reduce contact area, the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

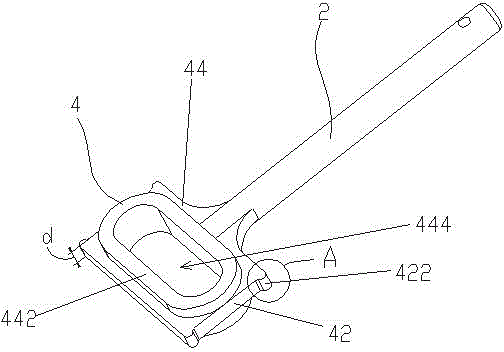

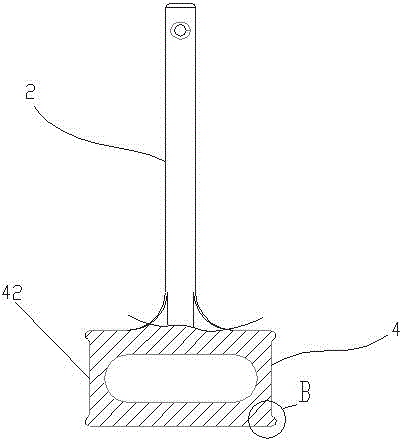

[0033] Such as Figure 1-3 As shown, a valve stem includes a cylindrical rod body 2 and a flat block-shaped sliding head 4 arranged at one end of the rod body 2 .

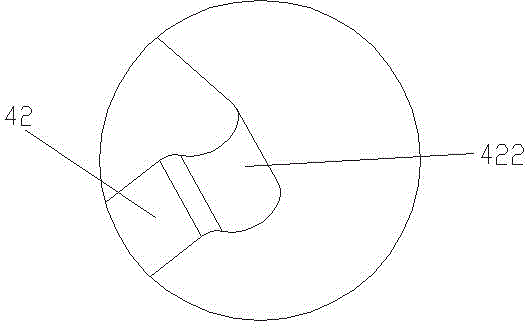

[0034] The sliding head 4 is symmetrical about the axis of the rod body 2 as a whole, and includes two first sides 42 respectively located on both sides of the rod body 2 and parallel to the axis of the rod body 2 . The two first sides 42 are respectively provided with outward protrusions 422 perpendicular to the first side 42 . Specifically, protrusions 422 are symmetrically provided at both ends of the first side 42 along the axial direction of the rod body 2 . The protrusion 422 is an arc-shaped protrusion protruding outward relative to the first side 42 where it is located. More specifically, the protrusion 422 has the same cross section at any position along the height direction of the first side 42, such as Figure 4 As shown, the cross-sectional profile is arc-shaped, preferably symmetrical arc-shaped.

...

Embodiment 2

[0039] As shown in the figure, a valve stem differs from Embodiment 1 in that the outer end surface 3 of the protrusion 422 is a plane.

Embodiment 3

[0041] As shown in the figure, a valve stem differs from Embodiment 1 in that the outer end surface of the rib 442 is an outwardly raised arc surface. More specifically, the ribs 442 have the same cross-section at any position along the circumferential direction, and the cross-sectional profile of the outer end is arc-shaped, preferably symmetrical arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com