Composite screw transporting vehicle

A transport vehicle and screw technology, applied in the direction of sales of raw material supply devices, clay preparation devices, unloading devices, etc., can solve the problems of difficult cleaning and cleaning, uneven mixing, easy to leak, etc., to improve cleaning efficiency, Improve the uniformity of mixing, avoid leakage and odor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

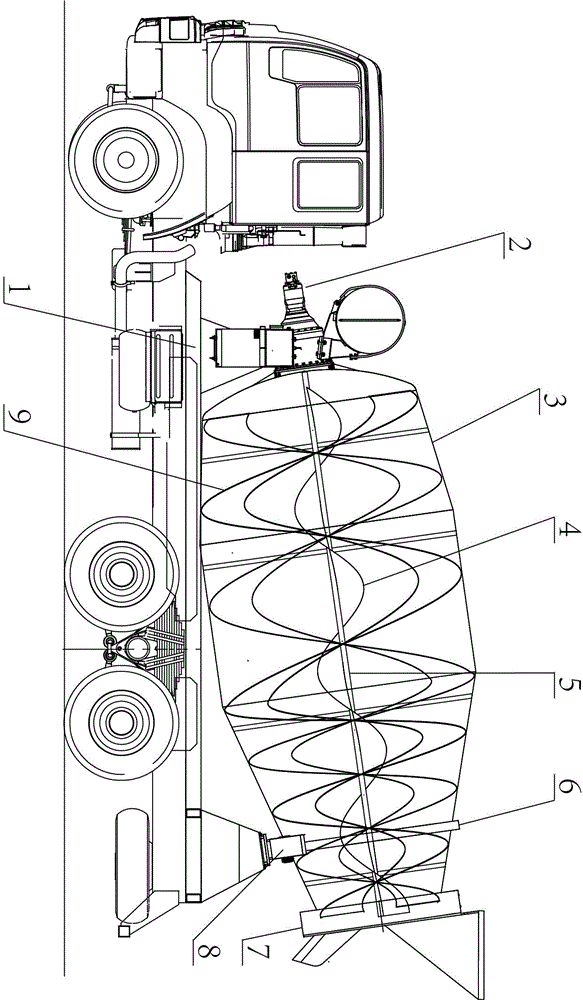

[0021] Such as figure 1 , this embodiment includes a vehicle frame 1 and a rotating material cylinder 3 rotatably seated on the vehicle frame 1 through a slewing bracket 8. The front end of the rotating material cylinder 3 is equipped with a power assembly 2 for driving the rotating material cylinder 3 to rotate. The rear end of the barrel 3 is connected with a feed port and a discharge port through a rotary sealing mechanism 7 . A rotary track 6 is installed on the outer wall of the rotating barrel 3 . The main blade 9 in the form of a spiral is installed on the inner wall of the rotating barrel 3 .

[0022] The rotary sealing mechanism 7 includes a rotating inner tube as a rotating component connected to the rear end of the rotary barrel 3 and rotates synchronously with the rotary barrel 3 , and the rotary sealing mechanism 7 also includes a floating connection with the frame 1 The fixed assembly includes a fixed outer cylinder sleeved outside the rotating inner cylinder, ...

Embodiment 2

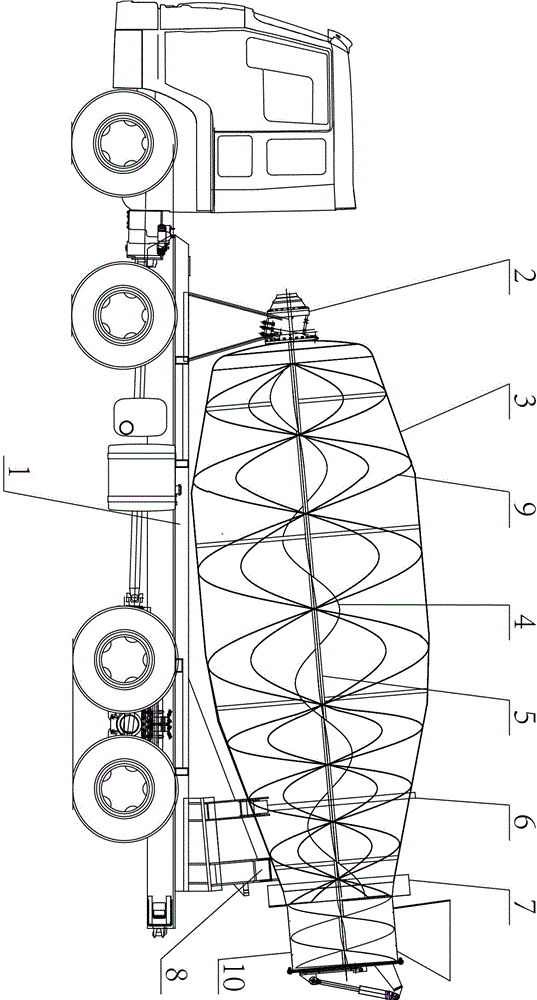

[0029] Such as figure 2 , this embodiment includes a vehicle frame 1 and a rotating material cylinder 3 rotatably seated on the vehicle frame 1 through a slewing bracket 8. The front end of the rotating material cylinder 3 is equipped with a power assembly 2 for driving the rotating material cylinder 3 to rotate. The rear end of the barrel 3 is connected with a rotary sealing mechanism 7 . A rotary track 6 is installed on the outer wall of the rotating barrel 3 .

[0030] The rotary sealing mechanism 7 includes a rotating inner tube as a rotating component connected to the rear end of the rotary barrel 3 and rotates synchronously with the rotary barrel 3 , and the rotary sealing mechanism 7 also includes a floating connection with the frame 1 The fixed assembly includes a fixed outer cylinder sleeved outside the rotating inner cylinder, and a seal is provided between the rotating inner cylinder and the fixed outer cylinder. The seal can be a common sealing tape, liquid-fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com