Polishing device and polishing system

A technology for polishing devices and installation areas, which is applied in the field of machinery and can solve problems such as high potential safety hazards, high physical labor intensity, and high labor intensity for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As described in the background technology, in the existing lathe polishing process, the operator needs to hold the sand skin, make the sand skin contact with the object to be polished, and rotate the object to be polished so that the surface of the object to be polished rubs against the sand skin to complete the object to be polished Polished surface. During the above-mentioned lathe polishing process, the operator always holds the sand skin and constantly applies force to the sand skin toward the object to be polished, so the labor intensity of the entire polishing process is relatively high; moreover, based on the continuous rotation of the machine tool spindle that controls the rotation of the object to be polished, There is a potential safety hazard of involving human body parts into the machine tool, and the operation is very dangerous.

[0039] Therefore, the present invention provides a polishing device and a polishing system.

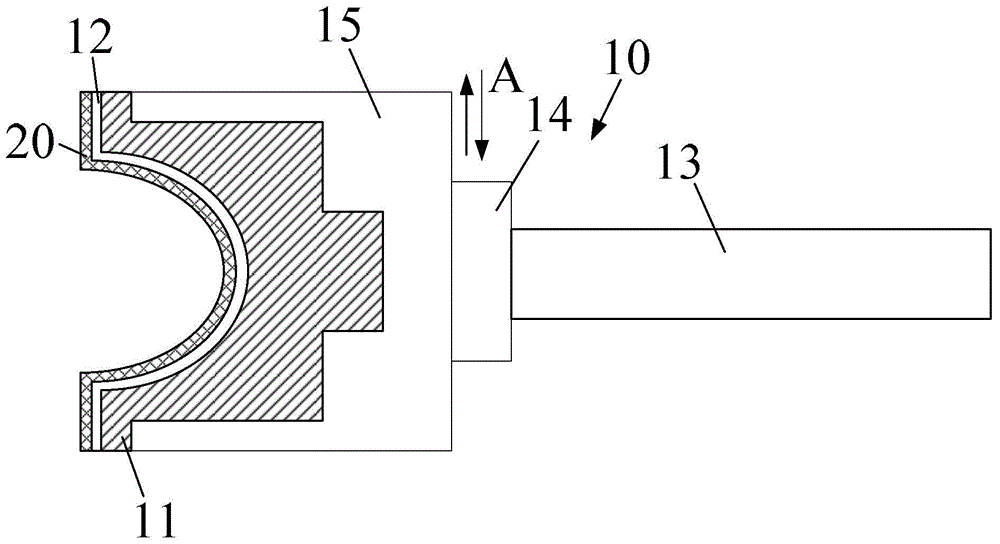

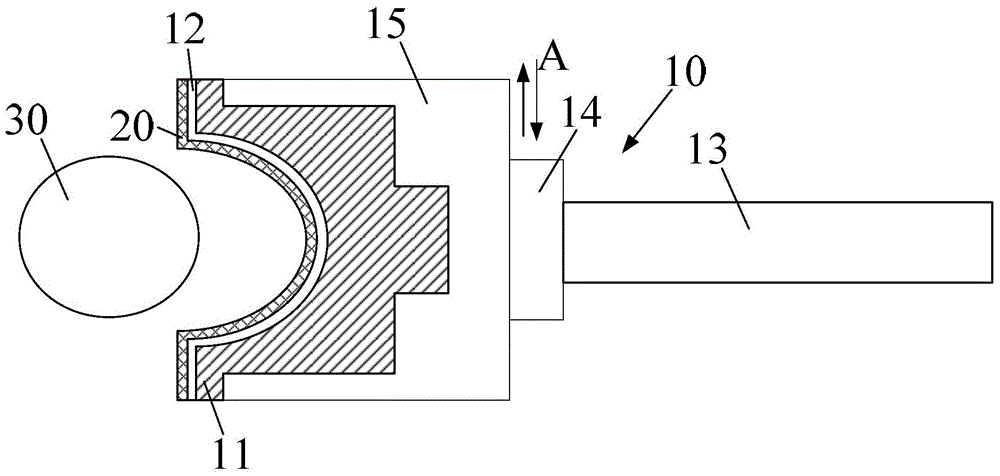

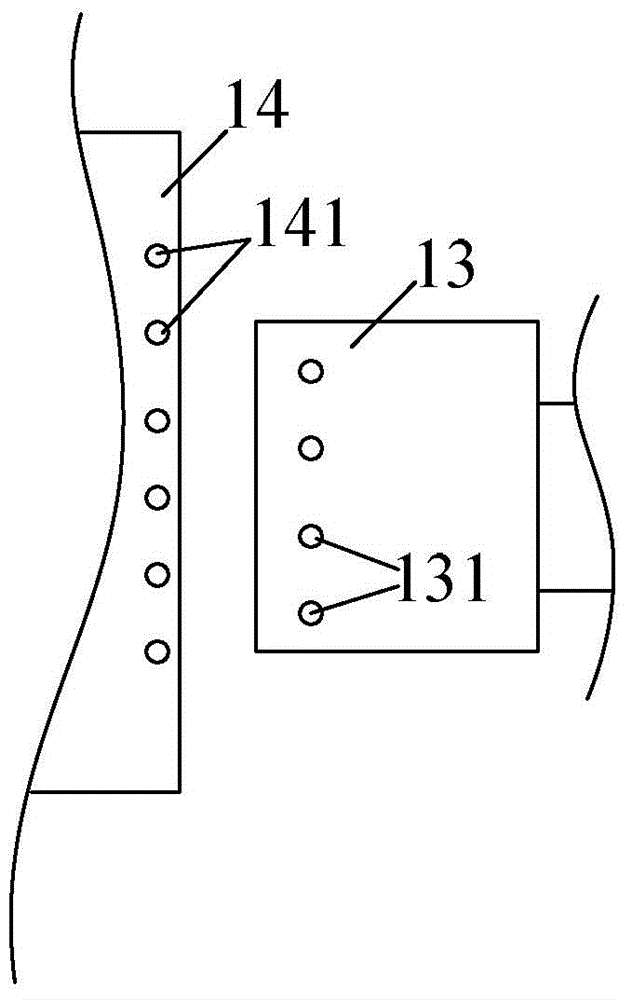

[0040] The polishing device inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com