Manufacturing method of railway switch block cast slide plate

A manufacturing method and technology of sliding bed boards, which are applied in the field of integrally cast sliding bed board manufacturing for railway turnouts, can solve the problems of reducing the maintenance workload of line maintenance personnel, achieve the effects of saving manufacturing time, reducing processing procedures, and ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

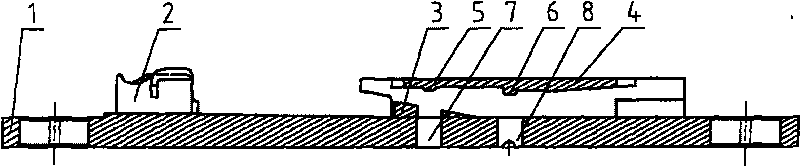

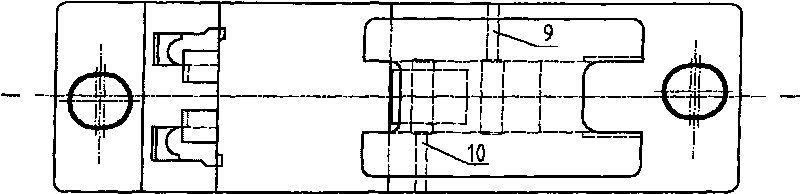

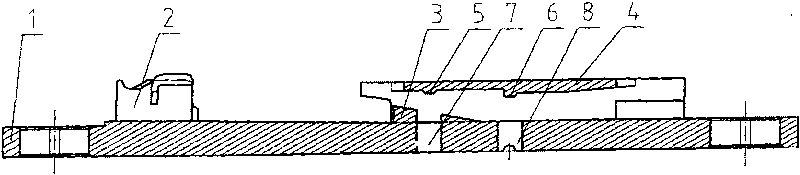

[0019] Attached below figure 1 , 2 An embodiment of the utility model is described in detail.

[0020] The monolithic sliding bed plate for railway turnout is composed of base plate 1, iron seat 2, guide iron 3 and platen 4, and its manufacturing method is as follows:

[0021] A. Select QT400-18-LT nodular cast iron, and use investment casting process to cast the bottom plate 1, iron seat 2, guide iron 3 and platform 4 into one body, and the rail bearing surface of bottom plate 1 is cast into a 1:40 slope, which is used for Support the basic rail to ensure the slope of the rail top. Casting flash and burr shall not be cut by flame, and shall be removed by gouging or grinding if necessary. QT400-18-LT nodular cast iron has high yield strength, low temperature impact resistance, and good casting molding effect.

[0022] B. In order to ensure the height and dimensional accuracy of the limit boss 5 and the support boss 6, two long grooves 7 and 8 are cast at the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com