Process for molding I-steel main welding seam non-back chipping full-penetration I-level component

A forming process and full penetration technology, applied in welding accessories, workpiece edge parts, welding equipment, etc., can solve the problems of high cost input, low production efficiency, and difficult control of plate deformation, so as to reduce production cost input and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

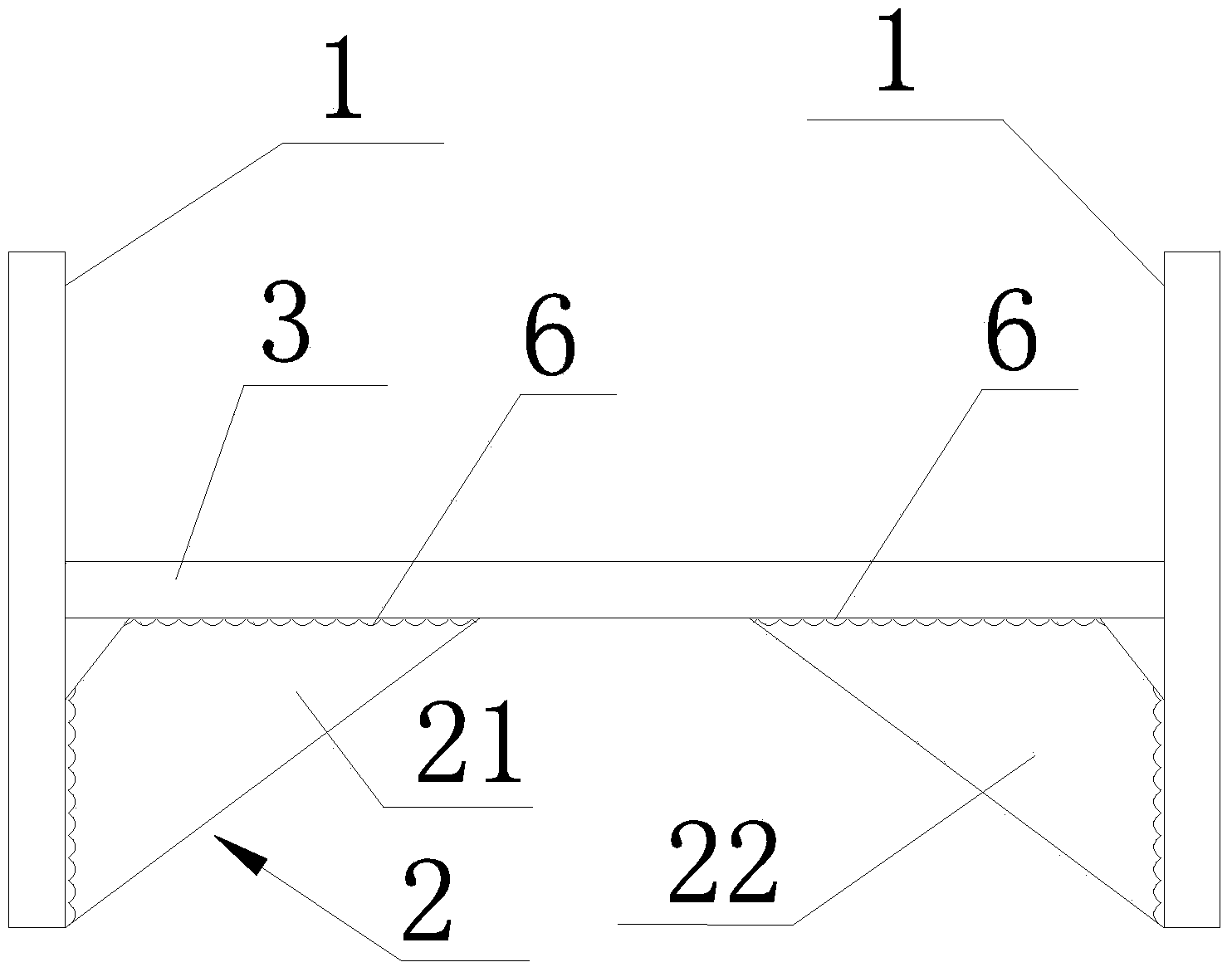

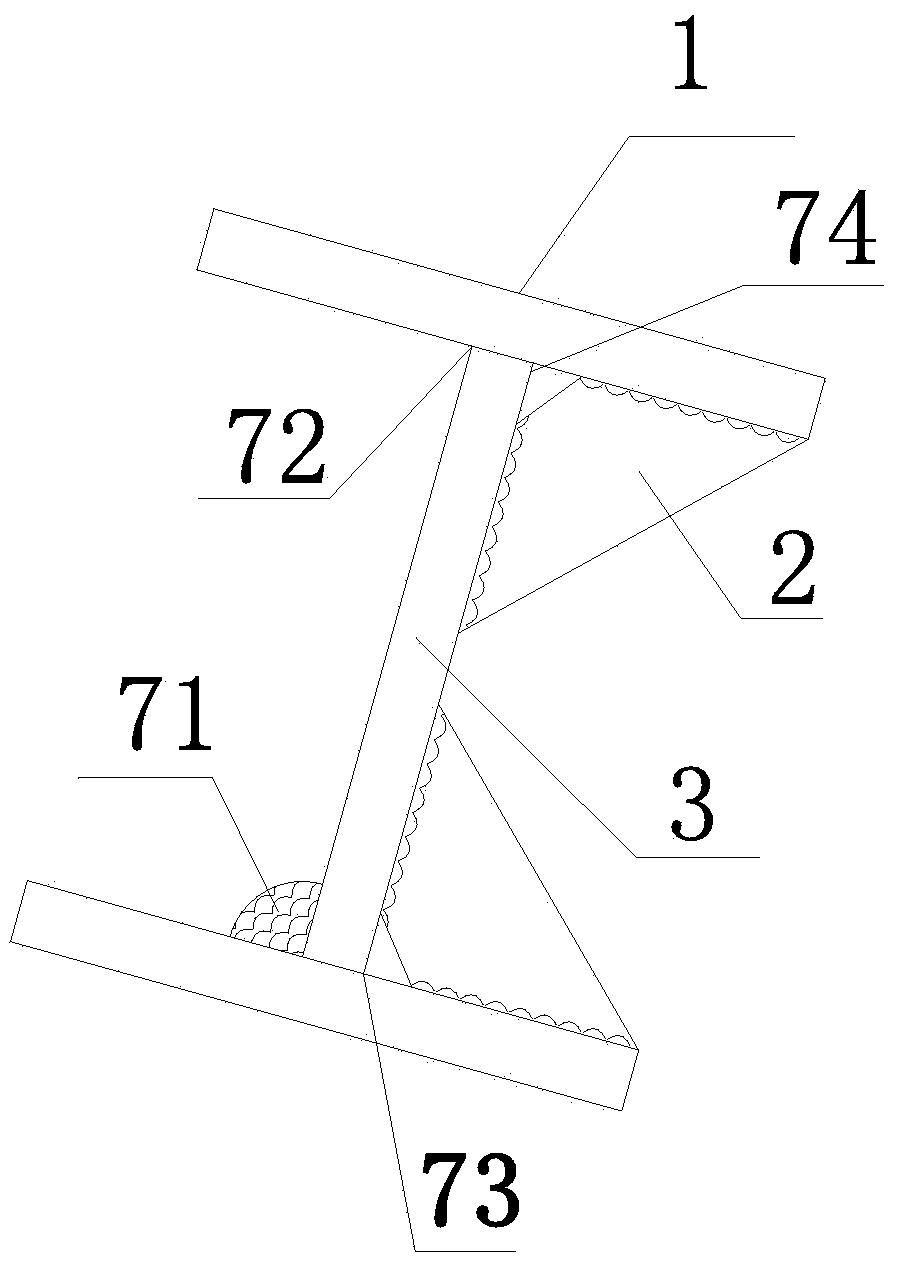

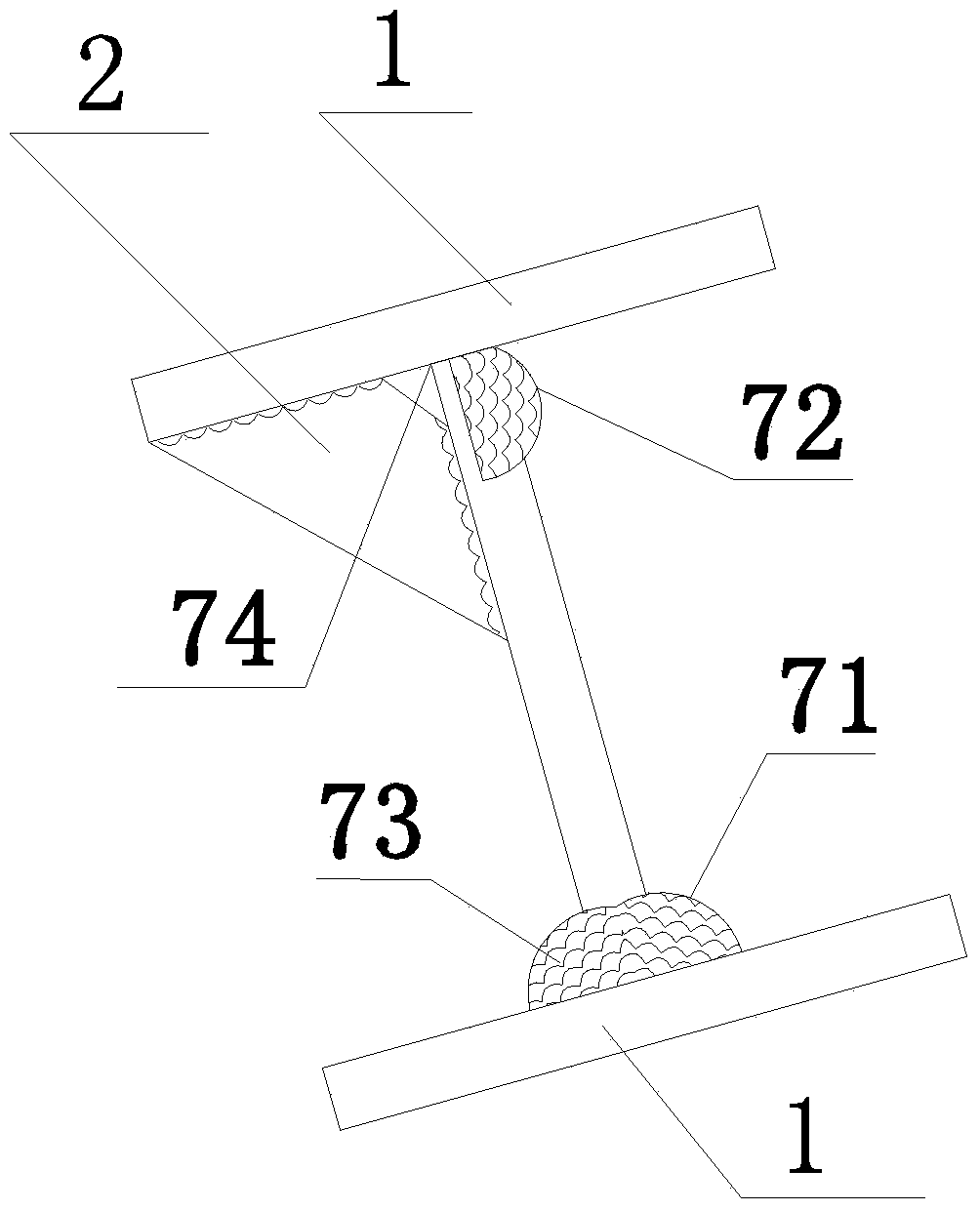

[0025]Referring to the accompanying drawings, it can be seen that the forming process of I-beam main welds with unclear roots and full penetration level I components is characterized in that it includes the following process steps, step 1: preparing several flange plates 1 and several process triangular stiffeners 2 and several webs 3; Step 2: Carry out weldability process test on flange plate 1 and web 3, check the weldability of flange plate 1 and web 3, and select the flange plate that has passed the inspection 1 and web 3 to enter the next step; step 3: cutting or shearing leveling of the flange plate 1 and the process triangular stiffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com