Fabricated ceramic tile wall surface and construction method thereof

A construction method and prefabricated technology, applied in covering/lining, building, building structure, etc., can solve the problems of high cost of modification, pollution on the construction site, long construction period, etc., to shorten the construction period, ensure the quality level, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

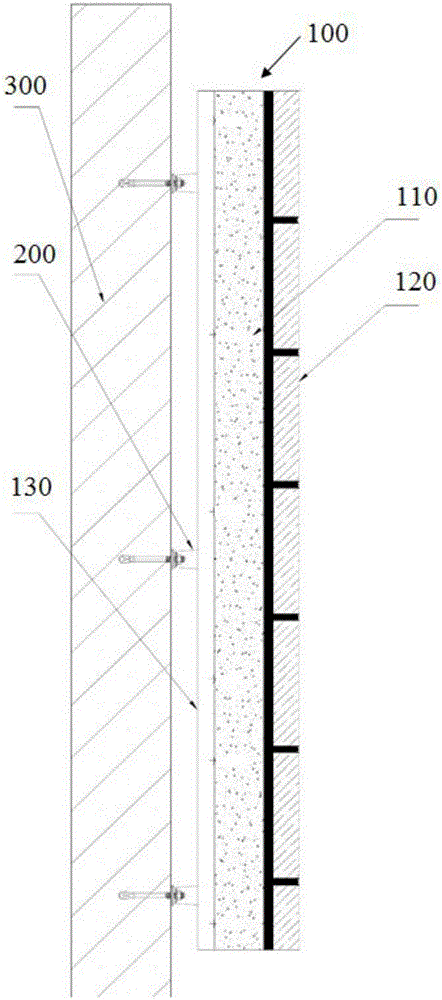

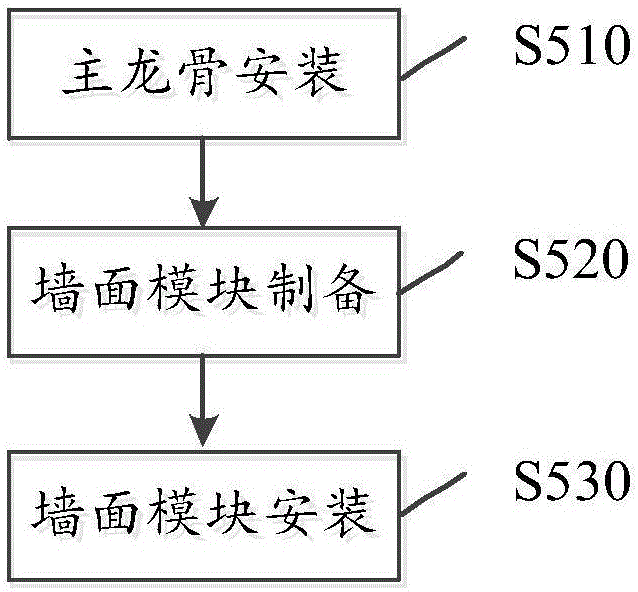

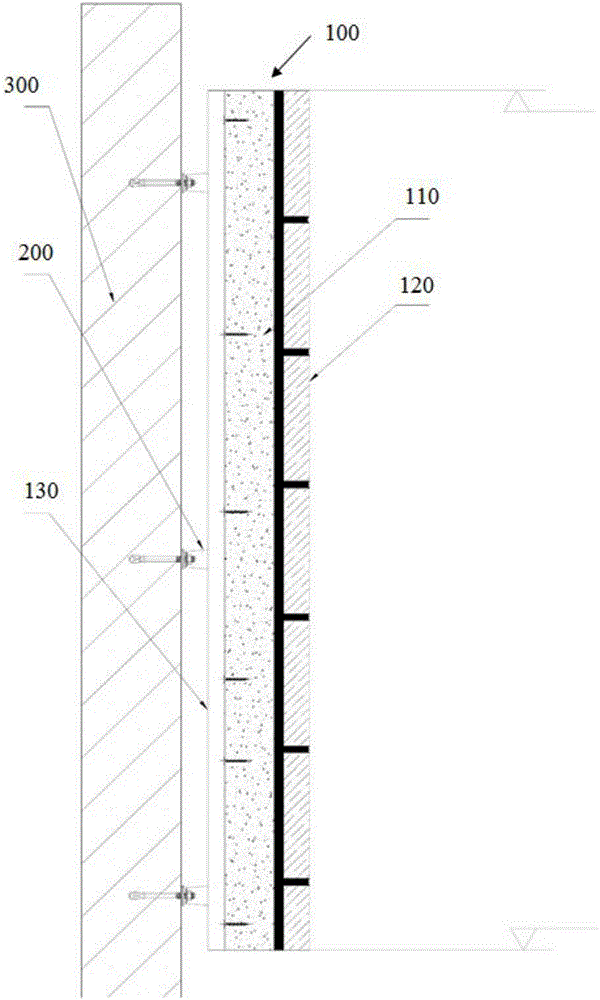

[0026] Preferred embodiments of the present disclosure will be described in more detail with reference to the accompanying drawings as follows. Although preferred embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the disclosure to those skilled in the art.

[0027] In recent years, people's demand for purchasing houses and living and working in peace and contentment has increased significantly, which has correspondingly driven the vigorous development of the interior decoration market. As a common way of decoration, ceramic tile walls have been welcomed by everyone. The existing ceramic tile wall project still adopts cement mortar paving or thin paste method, which is highly dependent on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com