An electroplating jig for holding slotted needles

A technology of electroplating fixtures and clamping grooves, which is applied in the direction of electrolytic components and electrolysis processes, etc. It can solve the problems that the inner wall of the needle groove cannot be electroplated with a hard chrome layer, the needle groove is worn, and the wear resistance is poor, so as to ensure the quality of electroplating and reasonable structure , to ensure the consistency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

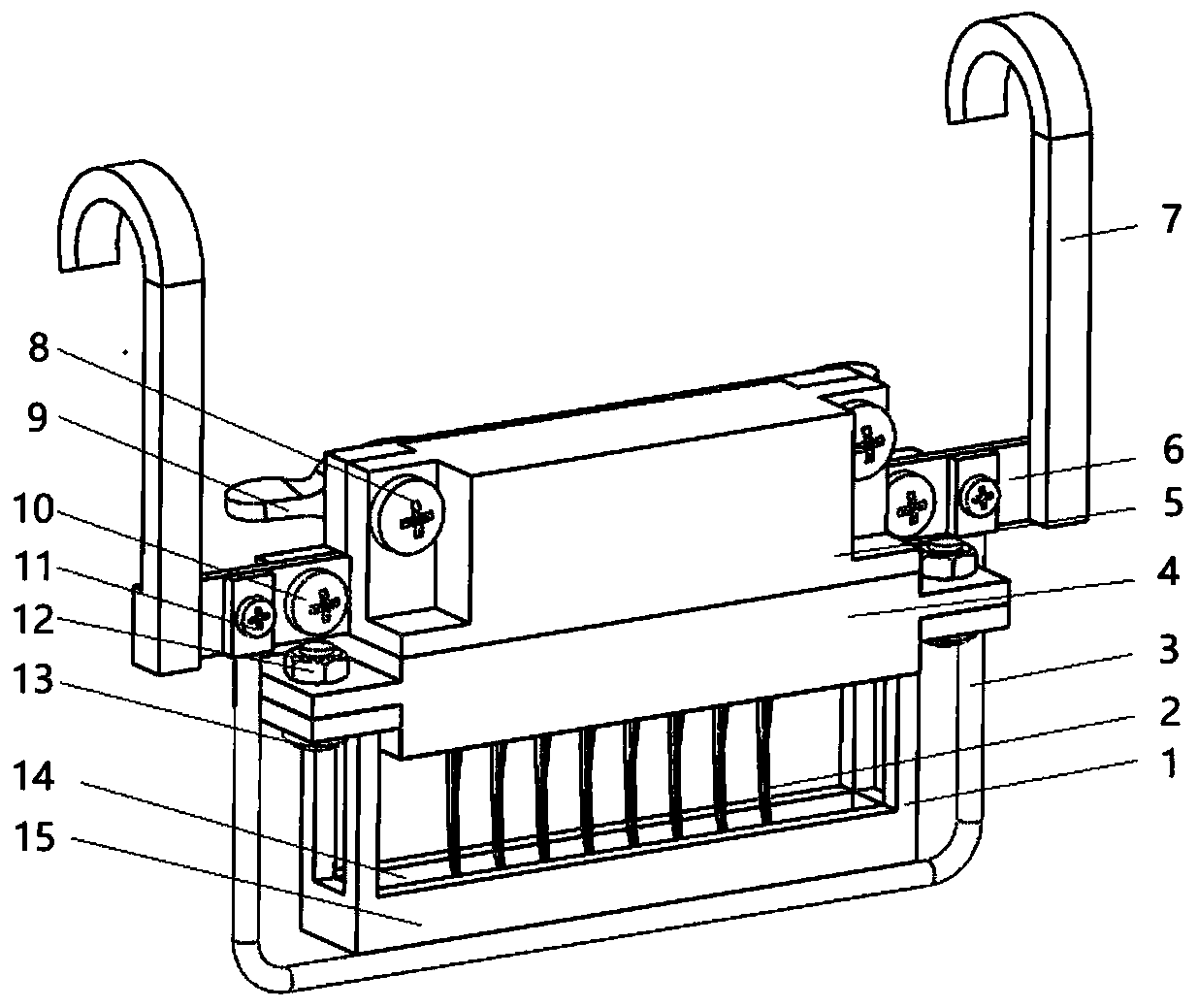

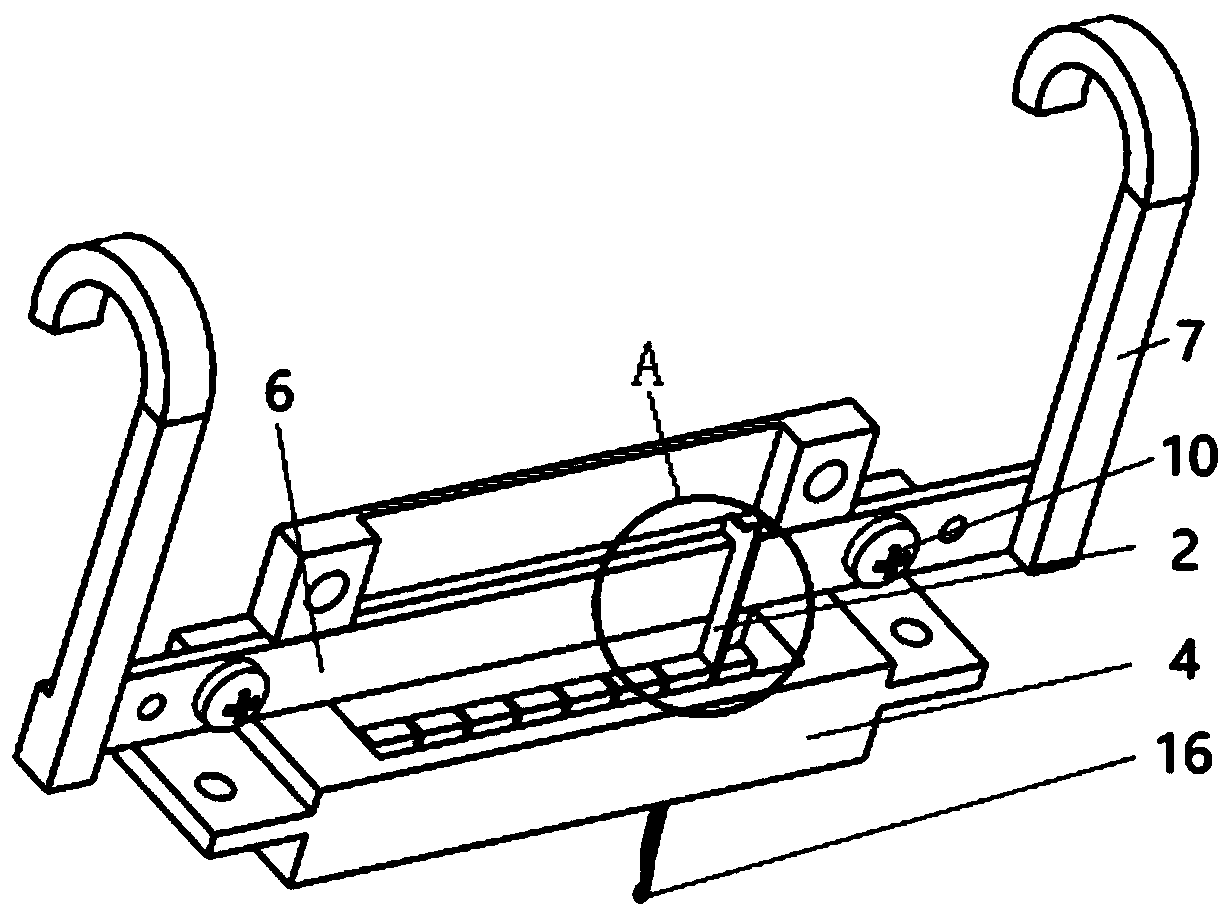

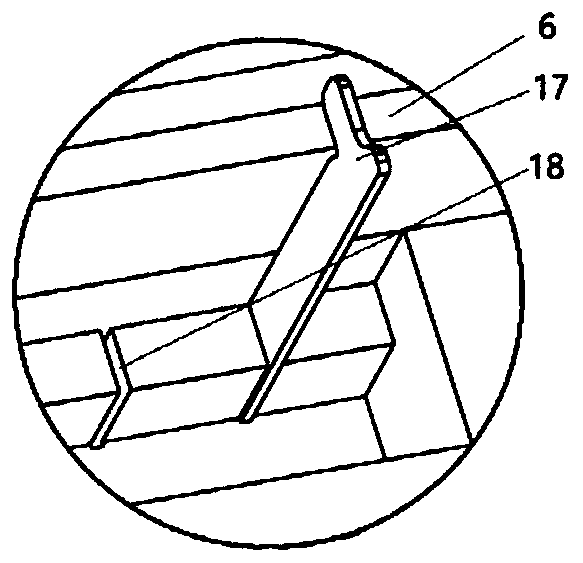

[0023] like Figure 1-5 As shown, an electroplating fixture for clamping a slotted needle includes a hoisting structure, a main body clamping structure and a flow blocking structure, wherein the main body clamping structure includes a plate groove 4, a cover plate 5 and a conductive plate 6, and the The plate groove 4 is connected with the cover plate 5, the conductive plate 6 is sandwiched between the plate groove 4 and the cover plate 5, fixed on the plate groove 4 by the screw a10 and the nut a21, the lower end of the plate groove 4 is provided with a The clamping groove 18 of the clamping groove needle 2, the groove needle 2 includes a groove needle hook 16, a groove needle pin 17 and a groove needle groove 19, and the connection between the cover plate 5 and the conductive plate 6 is provided with a foam glue 20 , for buffering and clamping the slotted needle 2, the choke structure includes a choke frame 1 and a "U"-shaped copper rod 3, the choke frame 1 is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com