Polypropylene wood-plastic composite material and preparation method thereof

A wood-plastic composite material and polypropylene technology, which is applied in the field of wood processing, can solve the problems of poor compatibility, decreased mechanical properties and service performance of wood-plastic composite materials, and difficulty in uniform dispersion, so as to improve the flame retardant performance and satisfy the production process. and the effect of performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

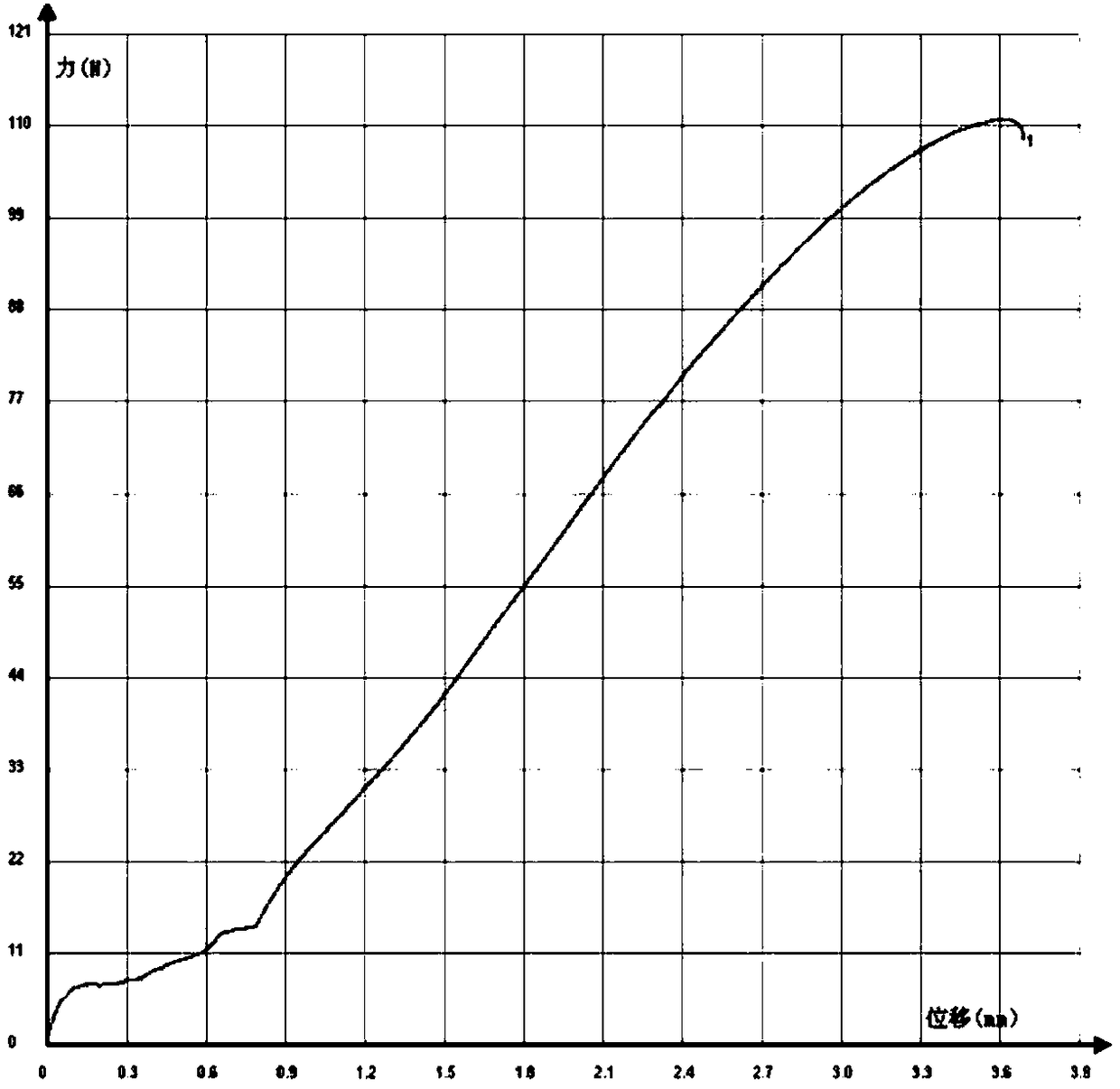

Embodiment 1

[0035] In practice, the present invention is made of masterbatch and auxiliary materials. The masterbatch is made of 50 parts of 10 fineness wood powder, 15 parts of LDPE, and 35 parts of PP in terms of weight and parts ratio;

[0036] The auxiliary materials are compounded from several materials, which are calculated in parts by weight: 0.3 parts of surface treatment agent, 0.4 parts of lubricant, 0.5 parts of modifier, 0.6 parts of flame retardant, and 0.6 parts of compatibilizer .

[0037] The preparation method is to accurately weigh the polypropylene molding material. When weighing a certain amount of wood flour to an accuracy of 0.1g, the molding material should not be too much or too little, so as to avoid the product size not being in place or defective. Open the internal mixer and preheat to 165°C for use. Add polypropylene, wood powder, and auxiliary materials into the internal mixer, and after the temperature is constant, turn on the motor and adjust the speed to 1...

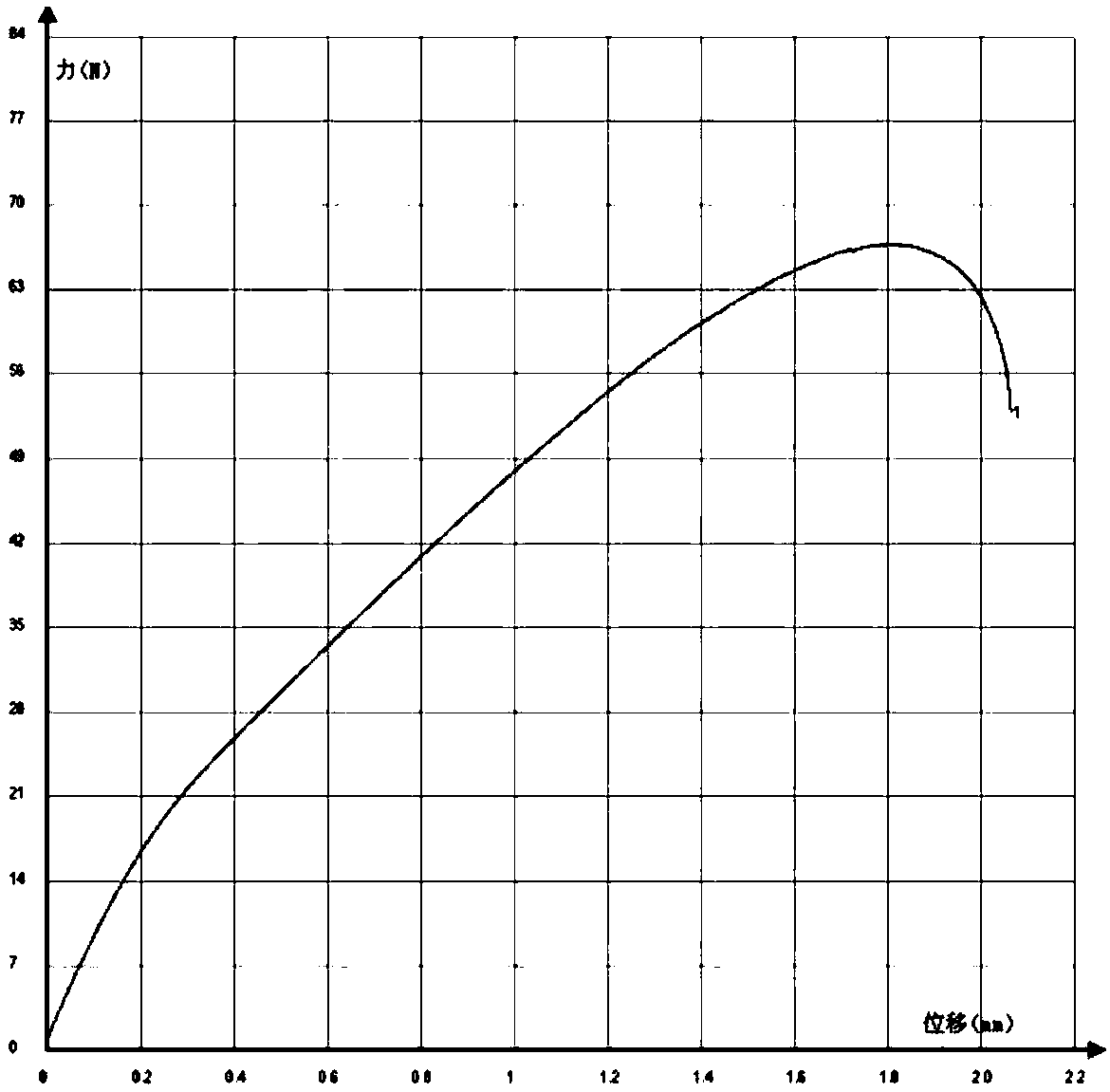

Embodiment 2

[0039] In practice, the present invention is made of masterbatch and auxiliary materials. The masterbatch is made of 50 parts of 10 fineness wood powder, 20 parts of LDPE and 30 parts of PP in terms of parts by weight;

[0040] The auxiliary materials are compounded by several kinds of materials, which are calculated according to the ratio of parts by weight: 0.6 parts of surface treatment agent, 0.6 parts of lubricant, 0.4 parts of modifier, 0.5 parts of flame retardant, and 0.3 parts of compatibilizer production;

[0041]The preparation method is to accurately weigh the polypropylene molding material. When weighing a certain amount of wood flour to an accuracy of 0.1g, the molding material should not be too much or too little, so as to avoid the product size not being in place or defective. Open the internal mixer and preheat to 165°C for use. Add polypropylene, wood powder, and auxiliary materials into the internal mixer, and after the temperature is constant, turn on the ...

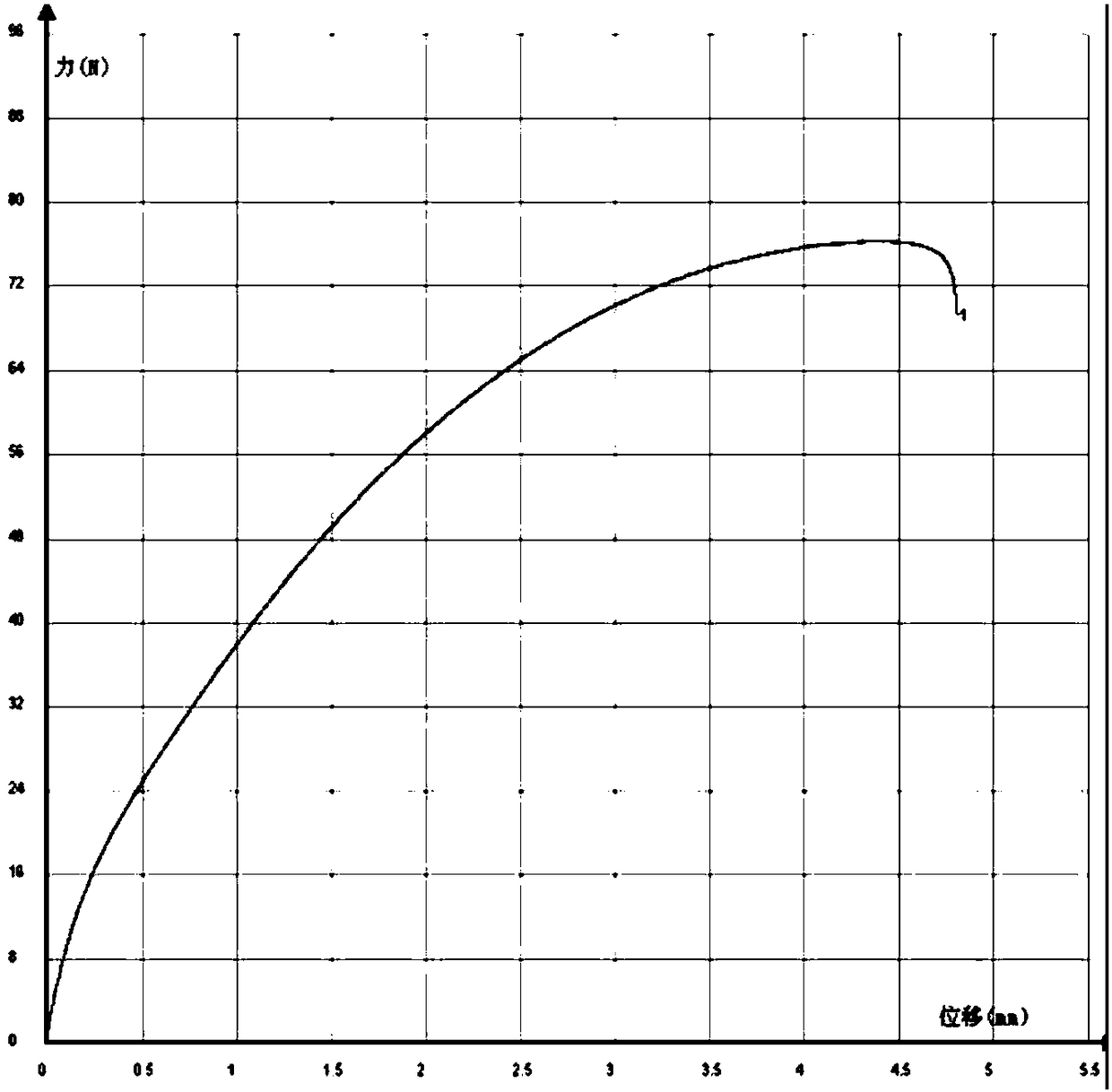

Embodiment 3

[0043] The present invention is made of masterbatch and auxiliary material in concrete implementation, and described masterbatch is calculated by weight and number:

[0044] Made of 50 parts of 10 fineness wood flour, 25 parts of LDPE, and 25 parts of PP;

[0045] The auxiliary materials are compounded by several kinds of materials, which are calculated according to the ratio of parts by weight: 0.5 parts of surface treatment agent, 0.3 parts of lubricant, 0.6 parts of modifier, 0.4 parts of flame retardant, and 0.6 parts of compatibilizer production;

[0046] The preparation method is to accurately weigh the polypropylene molding material. When weighing a certain amount of wood flour to an accuracy of 0.1g, the molding material should not be too much or too little, so as to avoid the product size not being in place or defective. Open the internal mixer and preheat to 165°C for use. Add polypropylene, wood powder, and auxiliary materials into the internal mixer, and after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com