Method for reducing finish mill steel biting impact

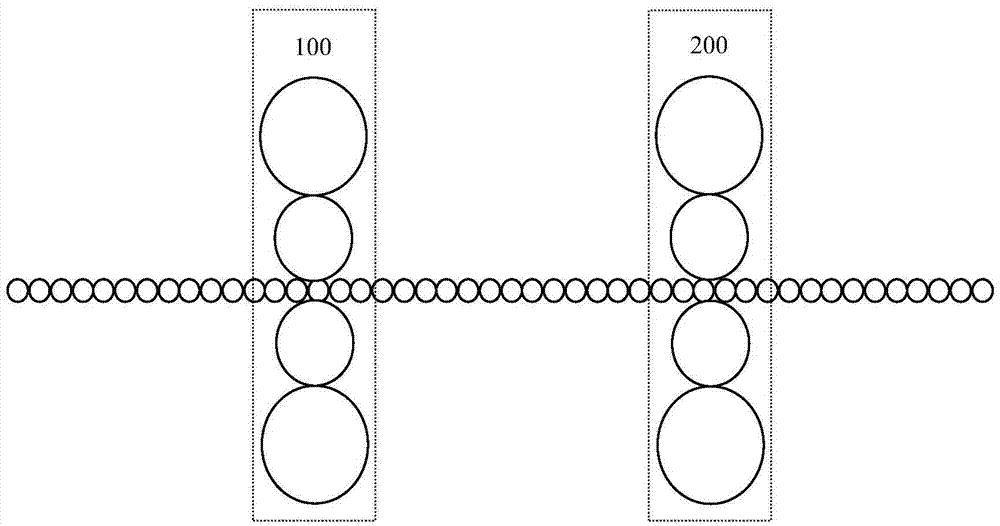

A finishing mill and steel biting technology, which is applied in metal rolling, metal rolling, and keeping the roll equipment in an effective state, can solve the problems of threatening equipment safety, prone to steel sticking, and large spindle load, so as to reduce steel biting. Impact, reduce impact, ensure the effect of production forward

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

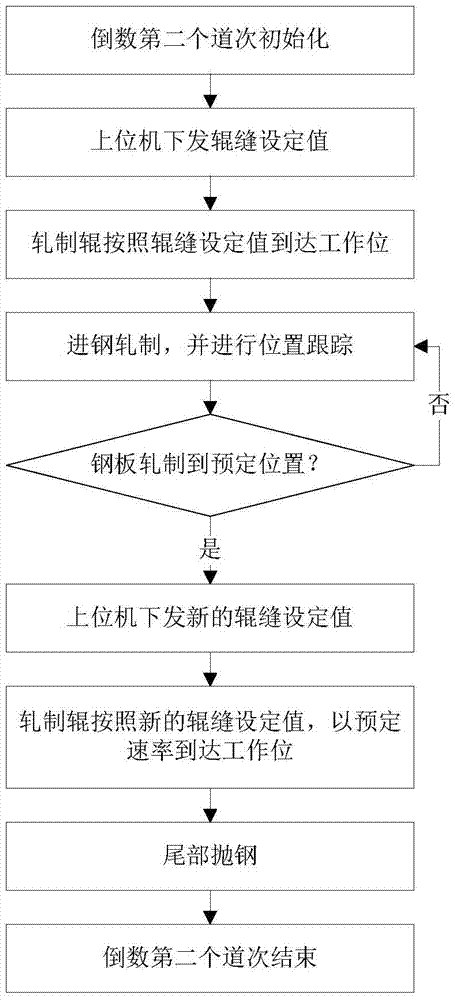

[0013] The method for reducing the steel biting impact of a finishing mill of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments, but it is not intended to limit the present invention.

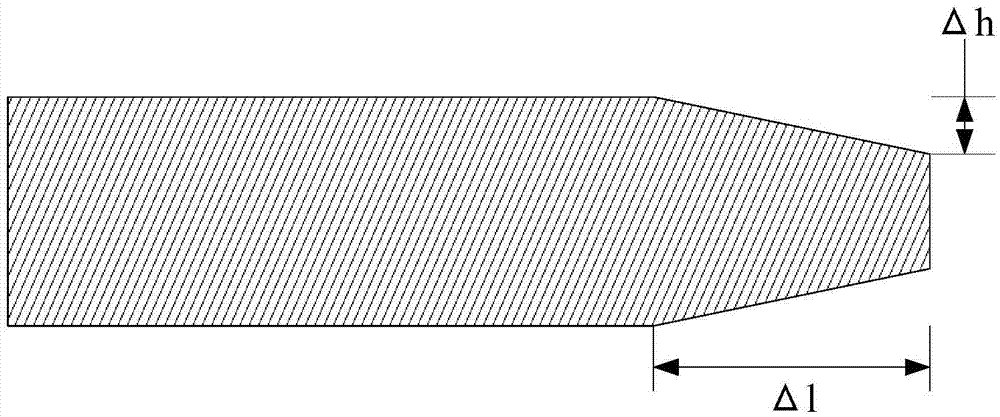

[0014] The excessive impact load of the steel biting of the finishing mill is mainly caused by the unreasonable distribution of the reduction pass, the factors of the slab itself (such as low temperature, warped head, etc.), and inaccurate pass calculation of the upper computer. These reasons are ultimately reflected in the factor of reduction.

[0015] The existing methods to improve the impact of steel biting in finishing mills usually adopt the strategy of changing the reduction in the finishing rolling stage. However, changing the reduction may affect the thickness of the slab at the finish rolling exit, which in turn affects the thickness of the product.

[0016] The present invention provides a method for reducing the impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com