Technology for preventing seepage of suspended water cooling pond wall of corex furnace by means of reaming, pipe penetrating and blocking

A cold water pool and pool wall technology, applied to pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of wet ground in the granulation pump room, rapid rise of water level, damage to the pool wall surface, etc., to eliminate Potential safety hazards, enhanced overflow water capacity, and the effect of ensuring efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

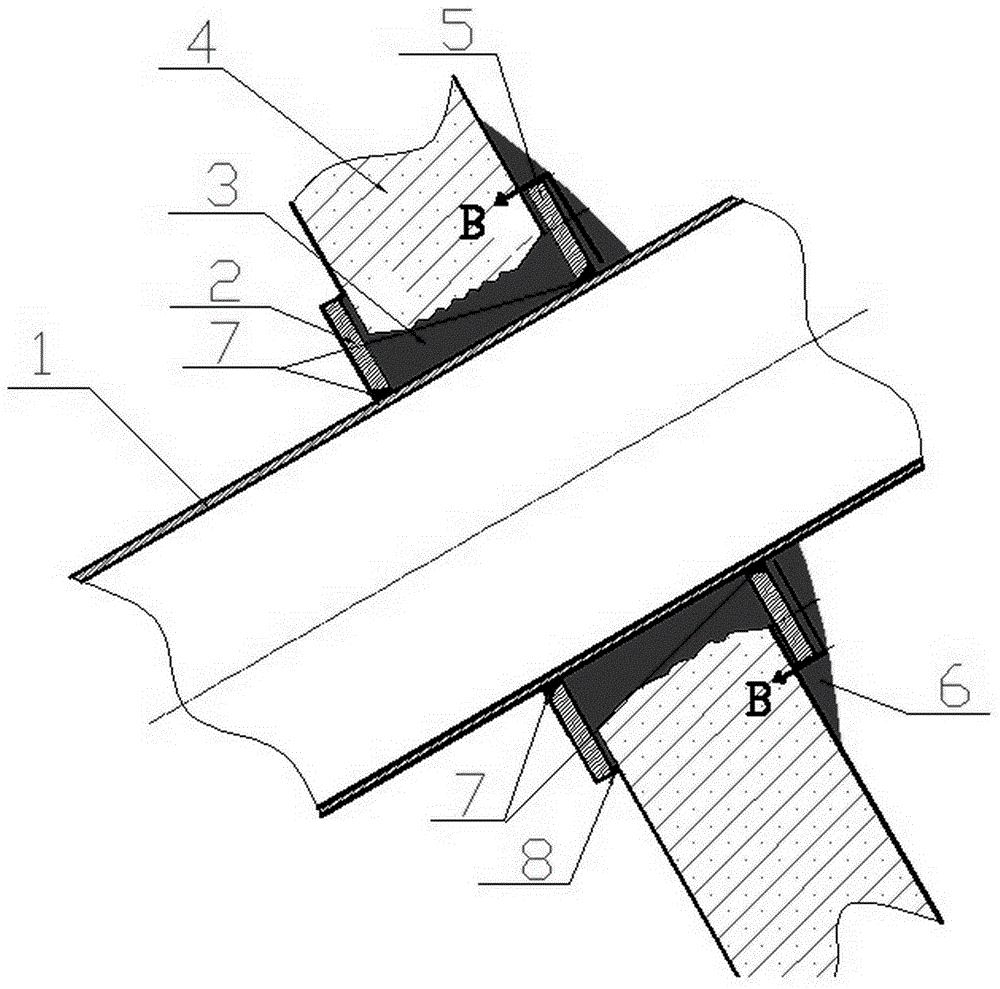

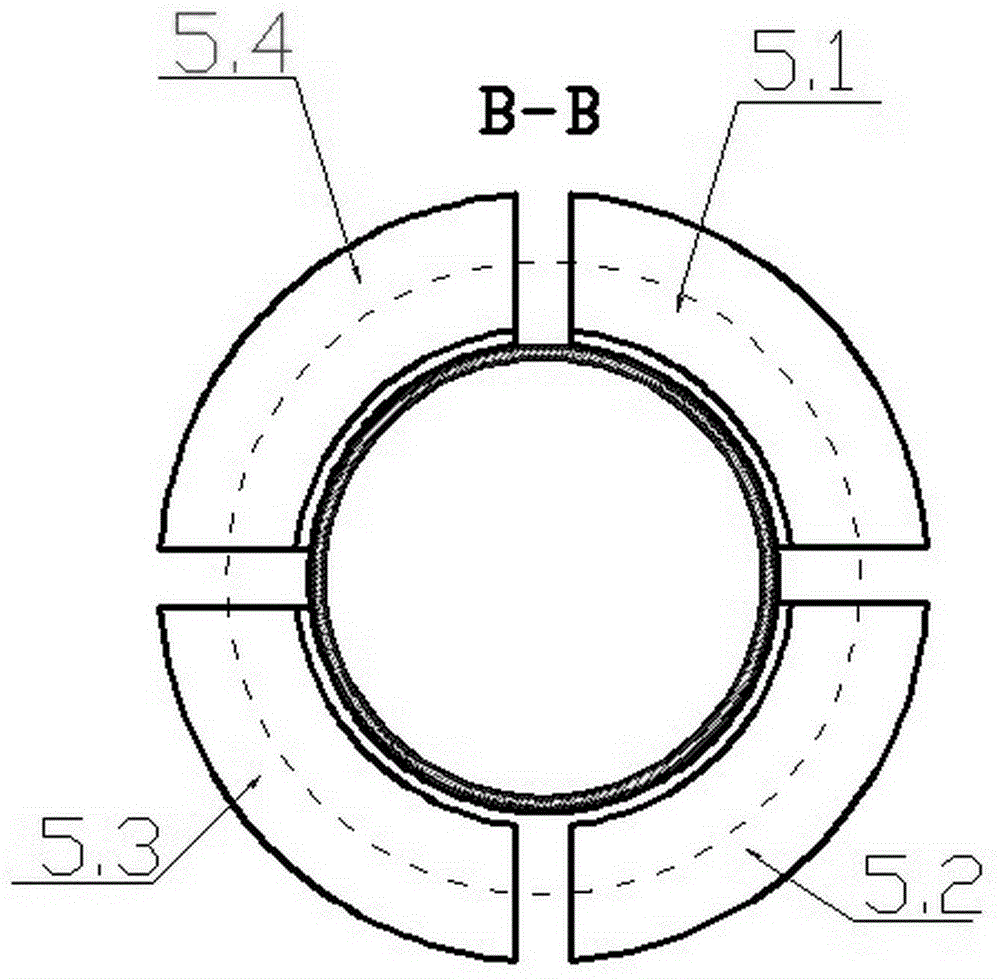

[0009] A leak-proof process for sealing the wall of the suspended cold water pool of Ouyeel furnace by expanding holes and piercing pipes, such as figure 1 , figure 2 As shown, the following steps are included: ① First, the original pipe hole on the pool wall 4 is continued to be reamed, so that when the pipe 1 passes through, there is a grouting distance of 40-70mm between the pipe wall and the hole wall, and the pipe 1 is in contact with the pool wall. Vertical, the surface of the waterproof layer inside the pool wall 4 is roughened; ② After the hole is expanded, the inner flange piece 2 is set on the pipe 1 in advance, or the inner flange piece 2 is put on the pipe 1 after passing through the pool wall 4 Split and welded on the pipe 1, the inner ring of the inner flange 2 is provided with a chamfer, the size of the chamfer is at least 45 degrees; It is fully welded with the outer wall of the pipe 1, and the weld seam 7 is relatively uniform due to the large chamfer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com