Turbocharger tube rubber

A turbocharger and rubber technology, applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve problems such as tube blank deformation, and achieve the effect of improving the hardness, stiffness and craftsmanship of the rubber compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] rubber G 40 copies

[0028] rubber 60 copies of IP

[0029] Reinforcing agent N774 0 parts

[0030] Strengthening agent N330 60 parts

[0031] Plasticizer TP-759 10 parts

[0032] Internal release agent 18D 2 parts

[0033] Vulcanizing agent DIAK1# 1.5 parts

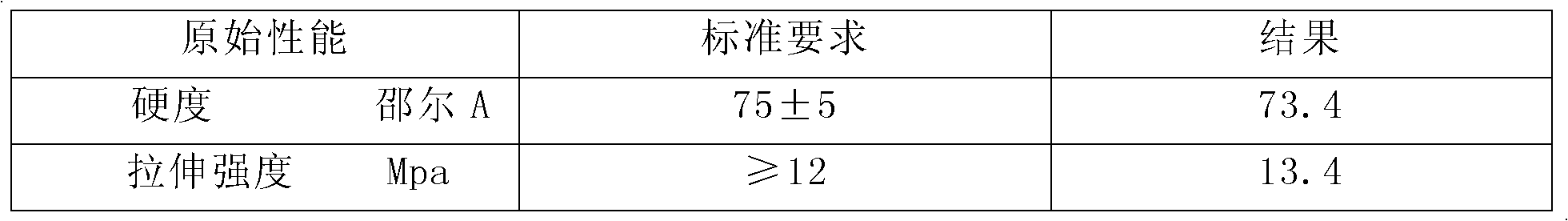

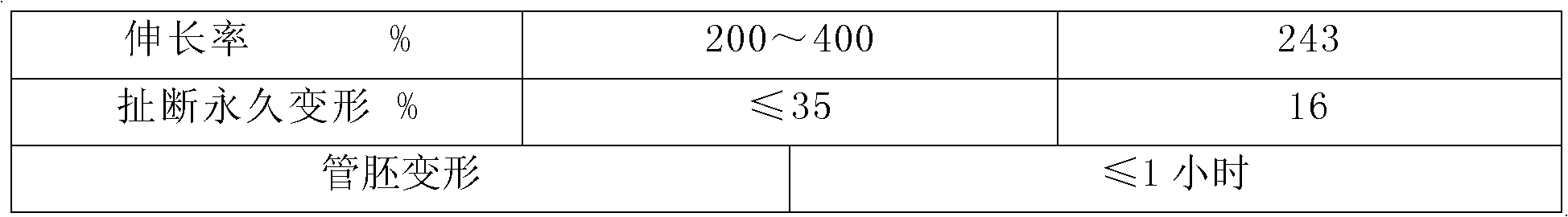

[0034] The performance and requirements of this formula according to public standards are as follows:

[0035]

[0036]

Embodiment 2

[0038] rubber G 40 copies

[0039] rubber 60 copies of IP

[0040] Strengthening agent N774 10 parts

[0041] Strengthening agent N330 50 parts

[0042] Plasticizer TP-759 10 parts

[0043] Internal release agent 18D 2 parts

[0044] Vulcanizing agent DIAK1# 1.5 parts

[0045] The performance and requirements of this formula according to public standards are as follows:

[0046]

Embodiment 3

[0048] rubber G 40 copies

[0049] rubber 60 copies of IP

[0050] Reinforcing agent N774 20 parts

[0051] Strengthening agent N330 40 parts

[0052] Plasticizer TP-759 10 parts

[0053] Internal release agent 18D 2 parts

[0054] Vulcanizing agent DIAK1# 1.5 parts

[0055] The performance and requirements of this formula according to public standards are as follows:

[0056]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com