High-intensity direct current electrical porcelain formula

A direct current, high-strength technology, applied in the field of electrical porcelain insulators, can solve the problems of low mechanical strength, poor electrical, electrical and thermal performance effects of electrical porcelain machines, and inability to greatly improve the bending strength of porcelain, so as to improve the glazing bending. Strength, good electrical properties, the effect of improving the flexural strength and thermal stability of porcelain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

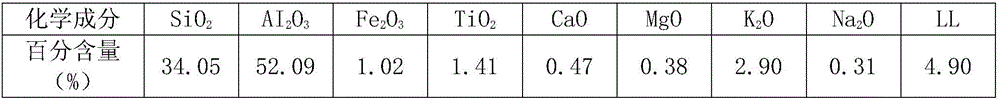

[0017] The high-strength DC electric porcelain formula of the present invention is composed of the following materials in parts by mass: 25 parts of Dongsheng soil, 20 parts of Jingyang soil, 22 parts of low titanite, 6 parts of Jiangjin clay, 1.5 parts of barium carbonate, α-Al 2 o 3 12 servings.

[0018] The formula of high-strength DC electric porcelain is composed of the following materials by mass: 30 parts of Dongsheng soil, 26 parts of Jingyang soil, 28 parts of low titanite, 10 parts of Jiangjin clay, 3 parts of barium carbonate, α-Al 2 o 3 18 servings.

[0019] The formula of high-strength DC electric porcelain is composed of the following materials in parts by mass: 27 parts of Dongsheng soil, 23 parts of Jingyang soil, 24 parts of low titanite, 8.5 parts of Jiangjin clay, 2.5 parts of barium carbonate, α-Al 2 o 3 15 servings.

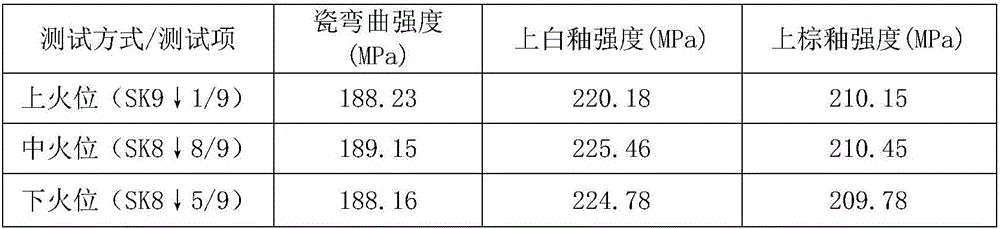

[0020] The formula of high-strength DC electric porcelain has the following characteristics:

[0021] (1) Using Jingyang soil instea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com