Auxiliary handle

An auxiliary handle and wrench technology, applied in the field of auxiliary handles, can solve the problems of whitening, breakage, unfavorable cost control and process requirements, etc., and achieve the effect of being favorable for cost control and satisfying the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is a further non-limiting detailed description of the technical solution of an auxiliary handle involved in the present invention in combination with preferred embodiments and accompanying drawings.

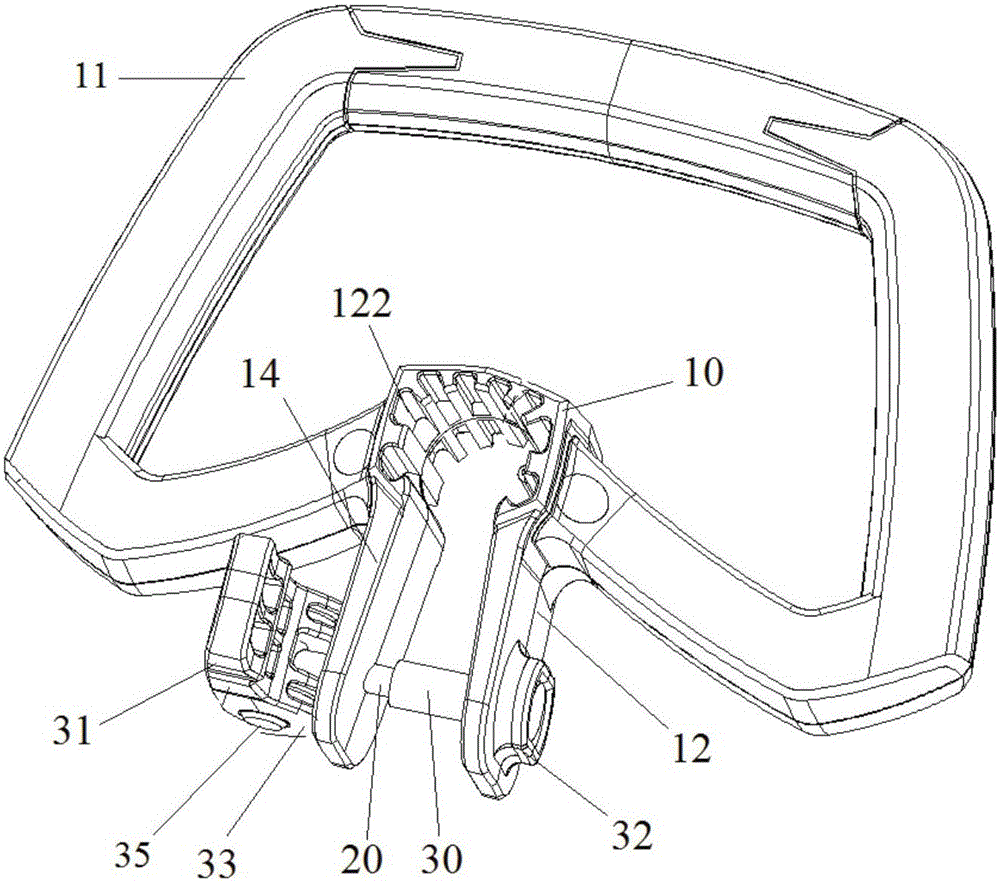

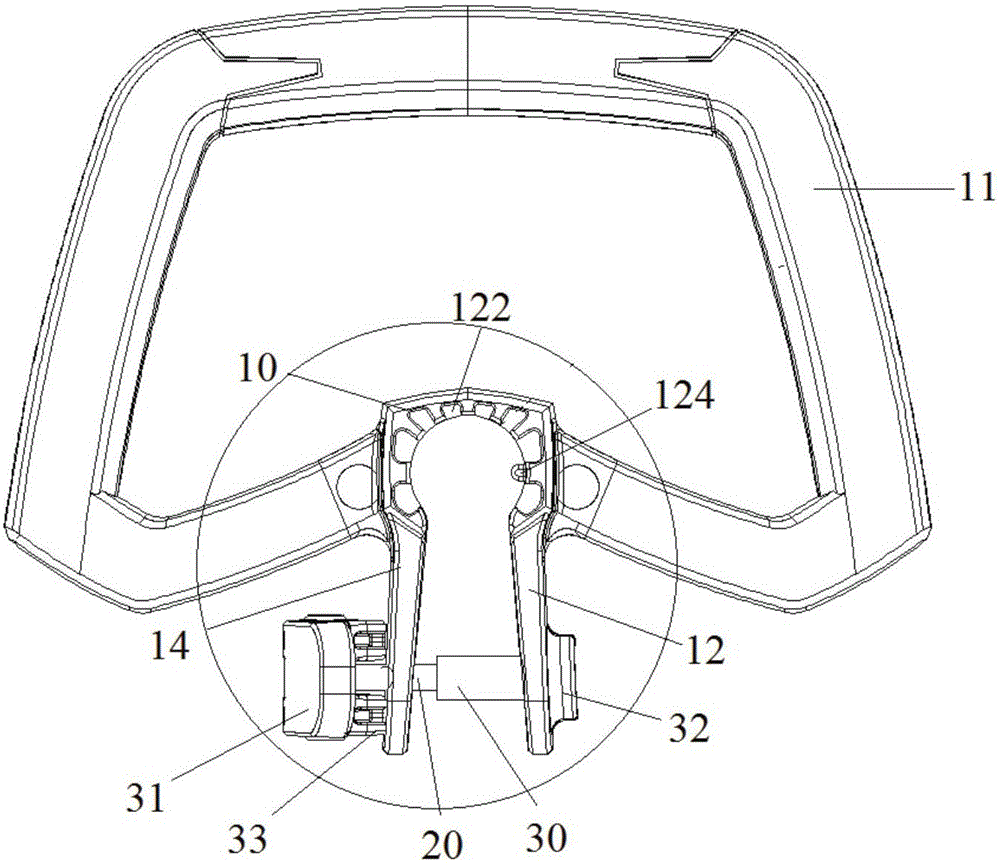

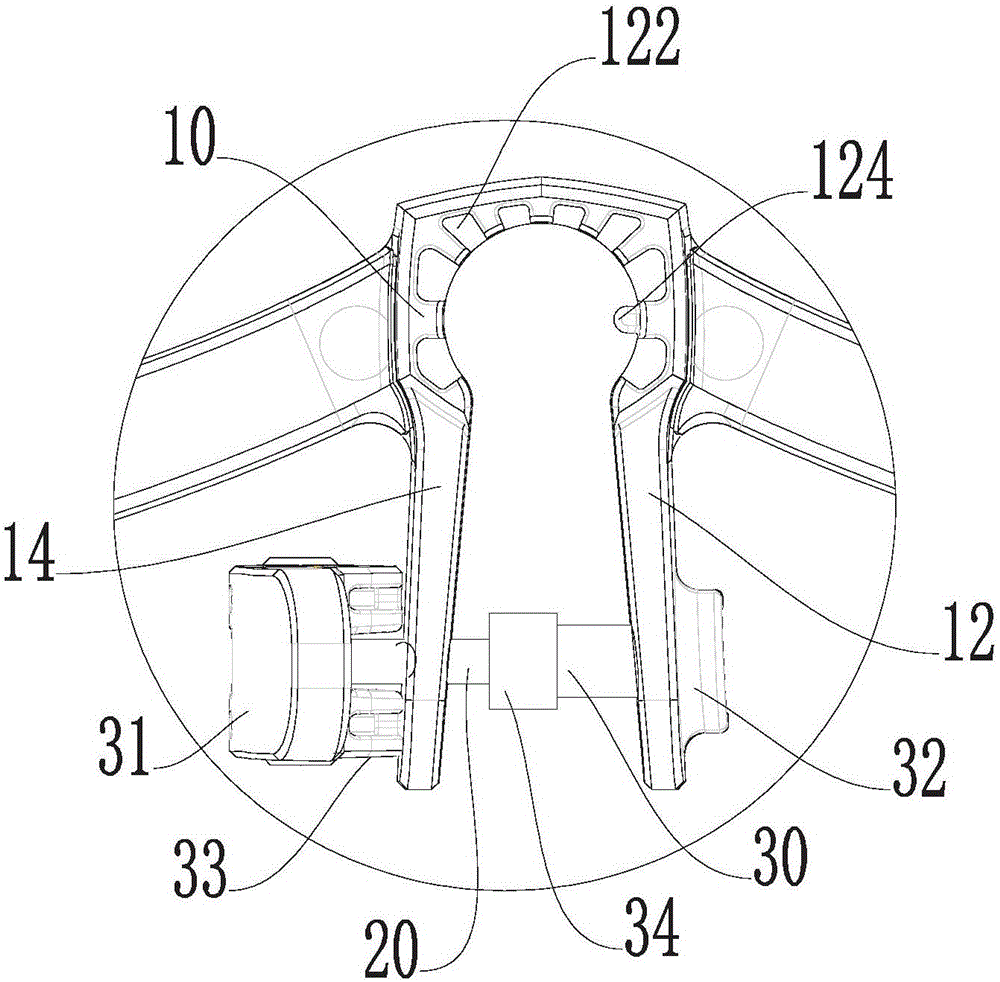

[0044] see figure 1 , 2 As shown in and 3, an embodiment of the present invention provides an auxiliary handle, which includes a sleeve rod portion 10 with an opening, a grip portion 11 and a clamping portion. The clamping portion includes a first clamping arm 12 and a second clamping arm 14 connected to both ends of the opening of the sleeve rod portion 10 . A buffer groove 122 and a positioning protrusion 124 are disposed on the inner wall of the shaft portion 10 .

[0045] Further, the first clamping arm 12 and the second clamping arm 14 are also provided with a clamping limiting device, which includes a connecting rod 20 and a clamp between the first clamping arm 12 and the second clamping arm 14 The limiting member 30, in one embodiment, the limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com