Composite filter element assembly and water purification system

A composite filter element and component technology, applied in the field of water purification, can solve the problems of asynchronous service life of the filter material structure and poor filtering effect, and achieve the effects of maximizing the utilization rate, improving the filtering effect and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

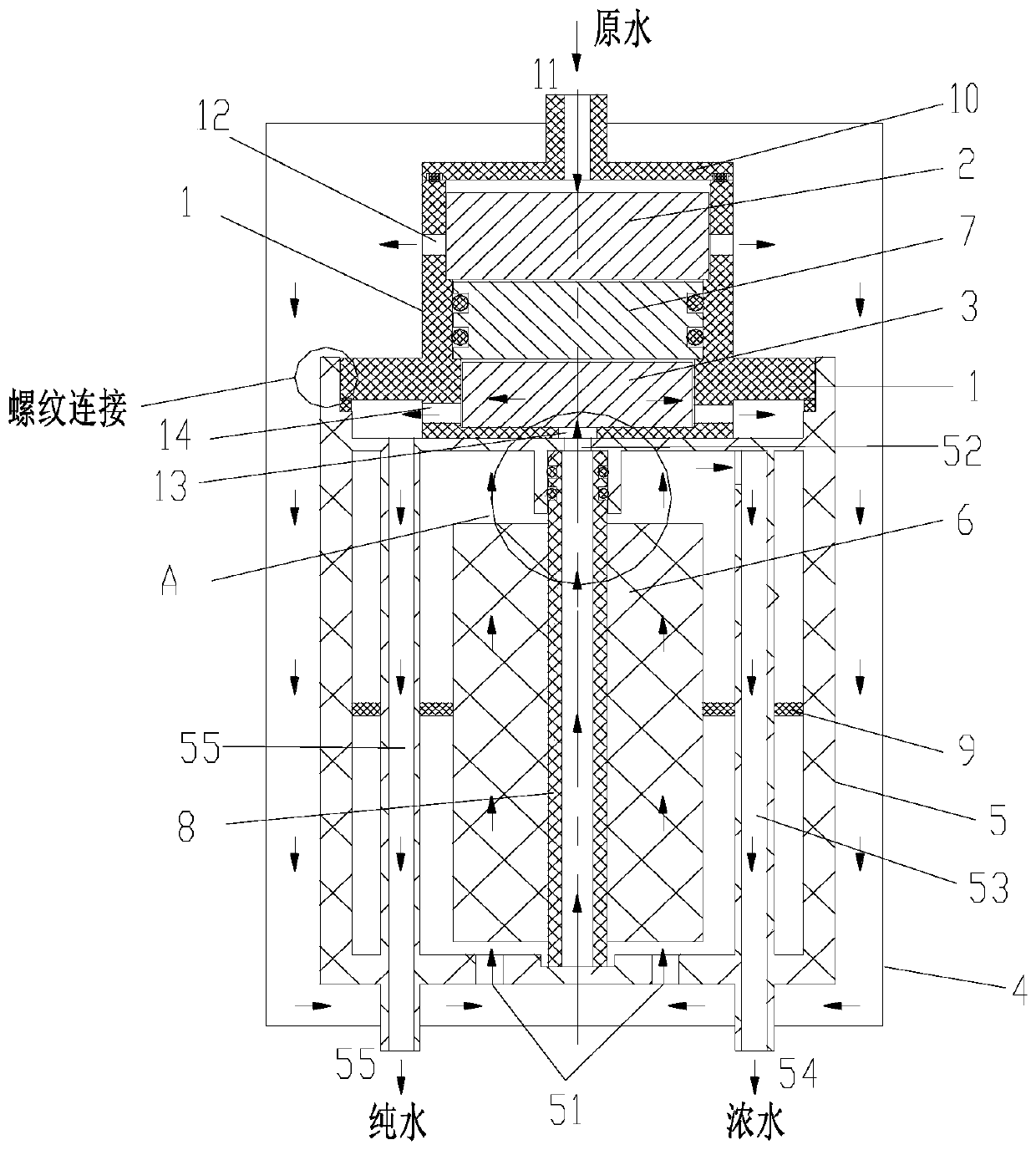

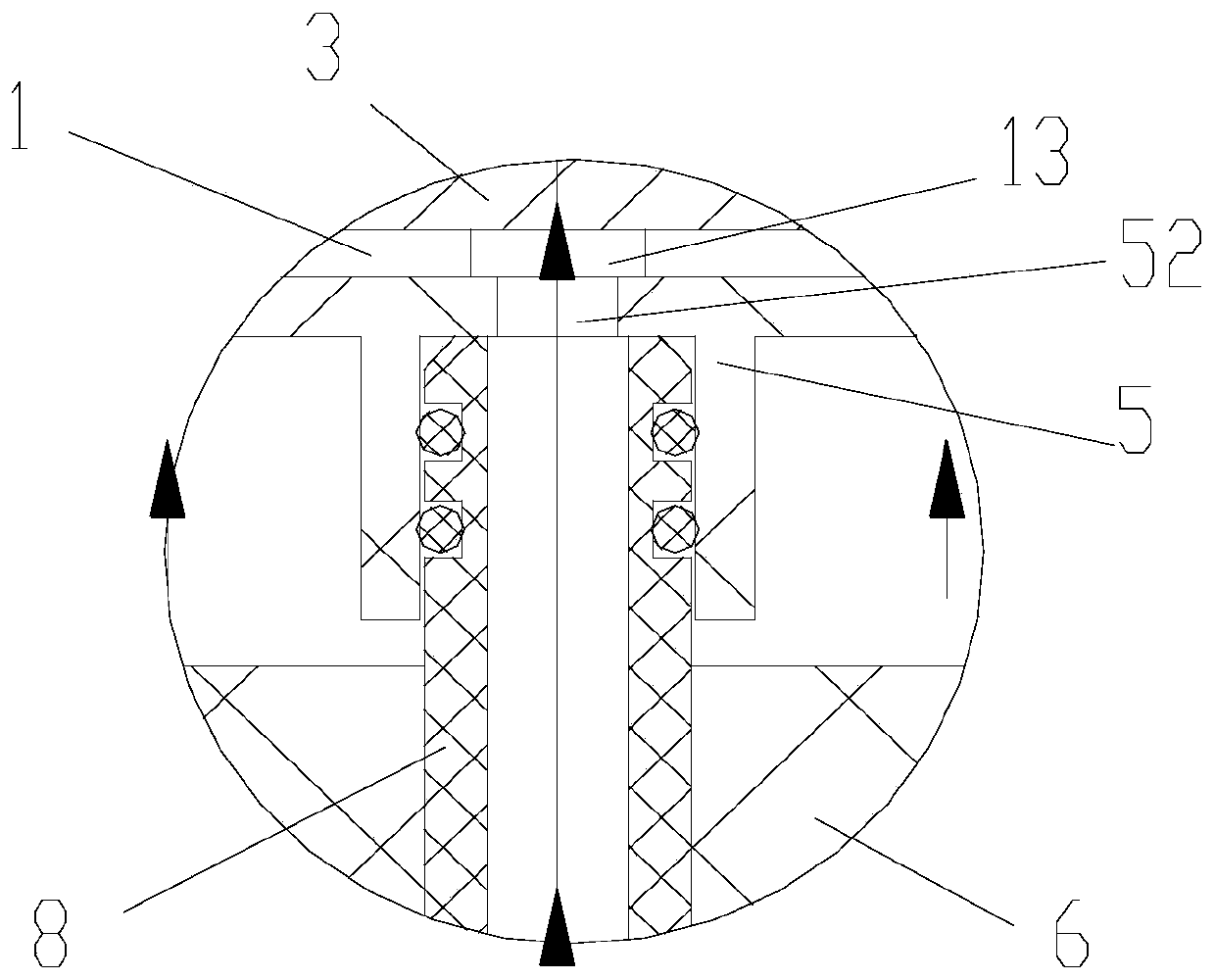

[0032] Such as Figure 1-2 As shown, the present invention provides a composite filter element assembly, which includes:

[0033] The first shell 1 is provided with a pre-filter element 2 and a post-filter element 3 at the same time; it also includes a filter bottle 4, and a raw water inlet 11 is arranged on the first shell 1 and communicated with the pre-filter element 2 respectively. And the first stage filter outlet 12, the first filter outlet communicates with the inside of the filter bottle 4;

[0034] Also includes a second housing 5, the inside of which is provided with a reverse osmosis membrane 6, the second housing 5 has a pre-filtered water inlet 51 communicating with the inside of the filter bottle 4, and a water inlet 51 connected to the first The second outlet 52 communicated with the rear filter element 3 in the casing 1 .

[0035] The present invention arranges two split shells, sets the pre-filter element and the post-filter element in the first shell, arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com