Baffle for special-shaped blank continuous casting machine tundish and preparation method thereof

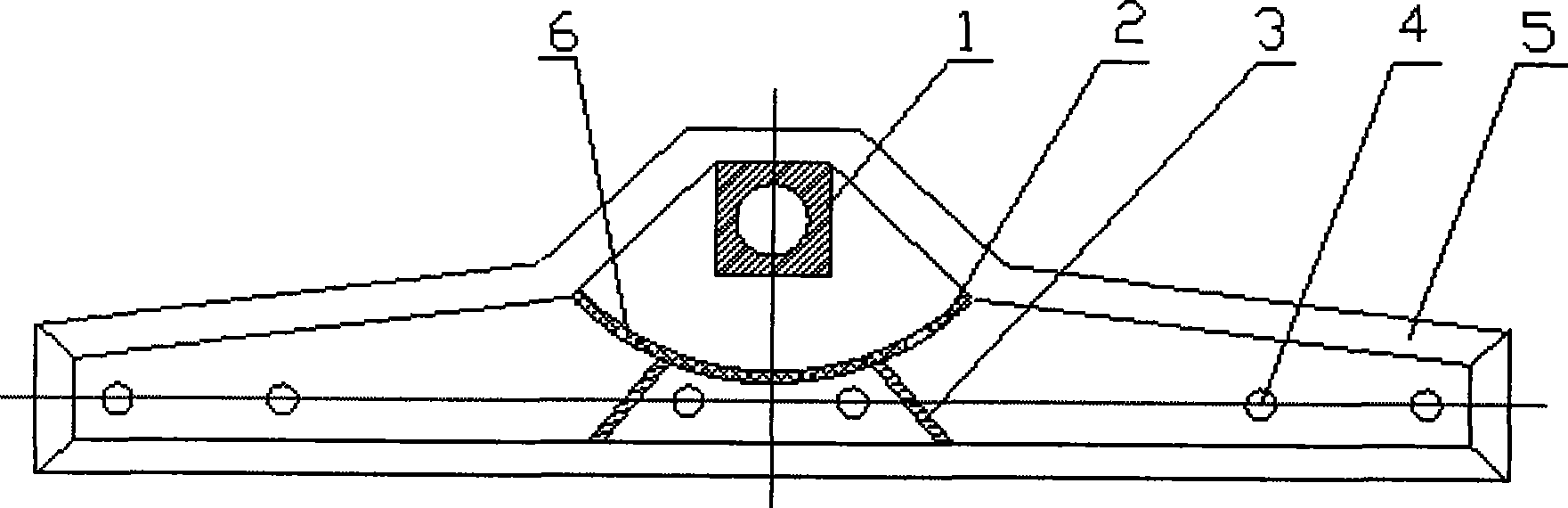

A special-shaped billet continuous casting and deflector technology, which is applied to the tundish process field of special-shaped billet continuous casting in iron and steel metallurgy, can solve the problem of uneven flow field of molten steel, and achieve the effects of reducing excess injection, realizing uniform distribution, and promoting floating removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A deflector for the tundish of a profiled billet continuous casting machine, which adopts magnesia prefabricated parts and is composed of the following materials by weight percentage: fused magnesia: 10-5mm28%; 5-3mm14%, 3-1mm25% , 1~0.074mm20%, 2 Ultrafine powder 1.5%.

[0033] The fused magnesia is a first-grade fused magnesia containing MgO≥97% (weight ratio), and the SiO 2 Ultrafine powder, wherein the SiO2 content is ≥ 92%, the particle size is less than 5 μm, and the particle size is less than 2 μm, accounting for 80-85%.

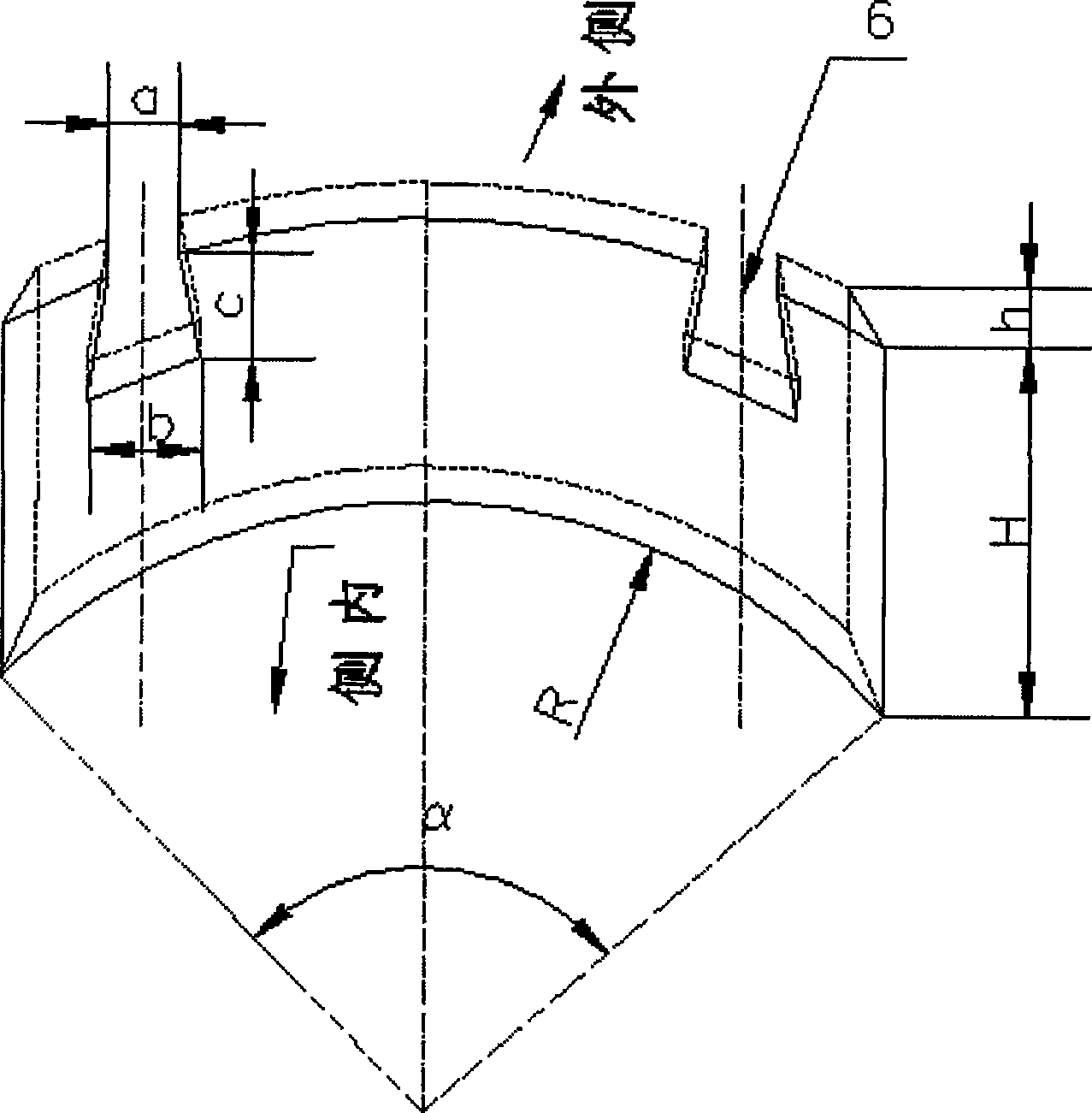

[0034] The deflector (2) has an arc-shaped overall structure, the radian α of the deflector is 92°, the height H is 750mm, the thickness h is 160mm, the upper width a of the trapezoidal groove is 120mm, and the lower width b is 200mm. The groove height c is 250 mm.

[0035] After weighing the above-mentioned materials according to the stated ratio, add them into the mixer for dry mixing for 2-3 minutes, add 6-8% water of the total weight of t...

Embodiment 2

[0039] Others are the same as embodiment 1, the difference is:

[0040] The guide plate used for the tundish of the profiled billet continuous casting machine is made of magnesia prefabricated parts, and is composed of the following materials according to the weight percentage: fused magnesia: 10~5mm particle size 30%, 5~3mm particle size 12%, 3~3mm particle size 1mm particle size 24%, 1~0.074mm particle size 21%, 2 Ultrafine powder 1.8%.

[0041] The deflector (2) has an arc-shaped overall structure, the radian α of the deflector is 95°, the height H is 800 mm, the thickness h is 180 mm, the upper width a of the trapezoidal groove is 102 mm, and the lower width b is 235 mm. The groove height c is 210 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com