Sulphuric acid tail-gas deep desulfurization method

A technology for deep desulfurization and sulfuric acid tail gas, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to increase the amount of ammonium sulfate recovered, reduce emissions, and increase investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

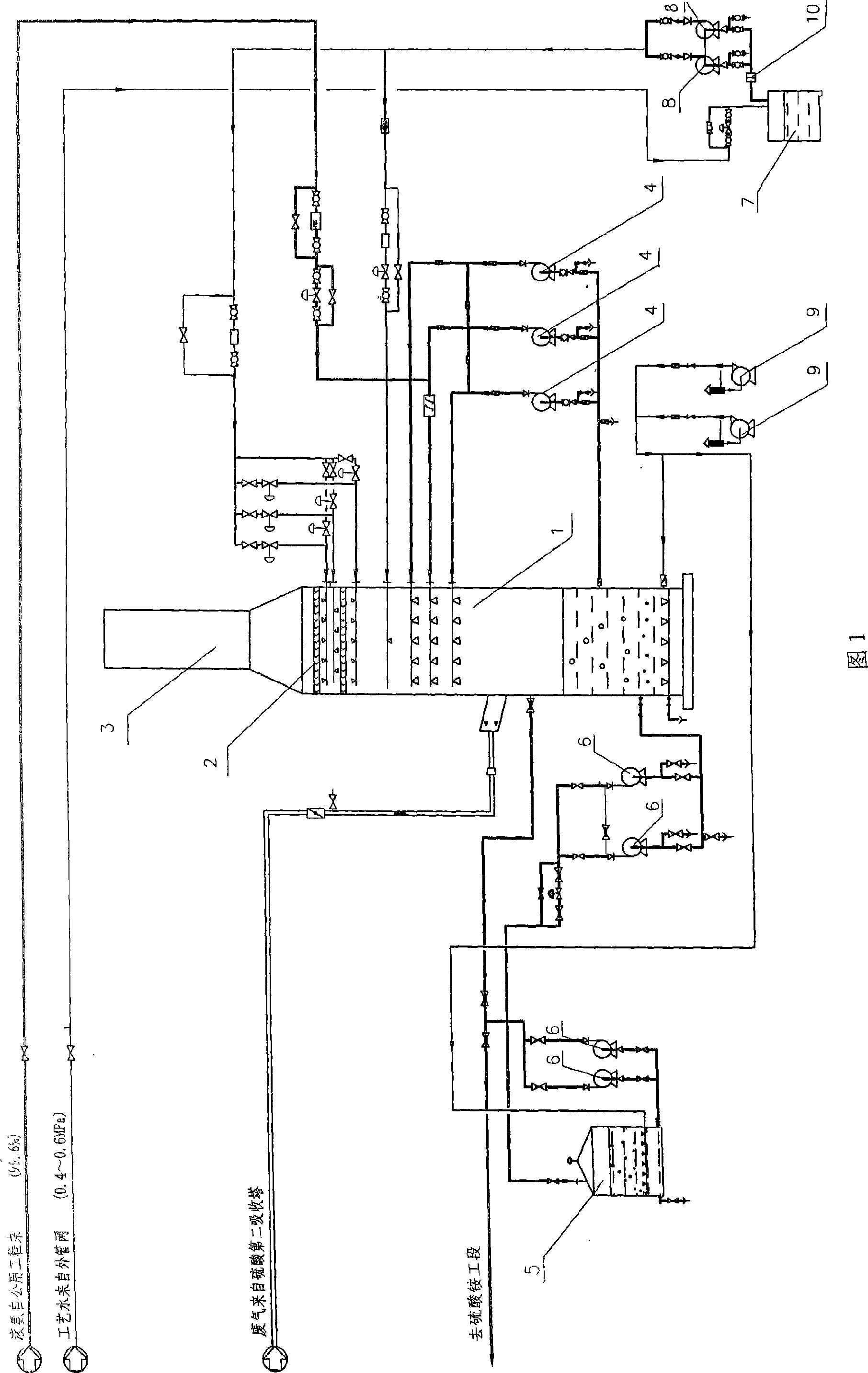

[0010] Example The sulfuric acid production of Guizhou Kailin Group Co., Ltd. is a sulfuric acid plant with an annual output of 2×800kt / a, which adopts the process of two rotations and two suctions.

[0011] The company added a desulfurization tower 1 after the second absorption tower, and the waste gas discharged from the second absorption tower enters the desulfurization tower 1 from bottom to top, and the ammoniated absorption liquid is used to absorb SO in the waste gas in countercurrent circulation. 2 Generate ammonium sulfite; the desulfurized tail gas passes through the demister layer 2 in the tower to remove acid mist, so that the water mist content is less than 75mg / m under standard conditions 3 , the purified tail gas is discharged at a high altitude through the tail gas chimney 3, and the SO in the exhaust tail gas 2 The concentration is lower than 100mg / m under standard conditions 3 .

[0012] Liquid ammonia and process water are continuously added to the desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com