Valve rod sealing type closed backpressure adjusting type steam security valve

A back pressure adjustment and sealing technology, which is applied in the field of safety valves, can solve problems such as excessive performance and poor sealing, and achieve the effects of improving stability, reducing leakage, and good reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

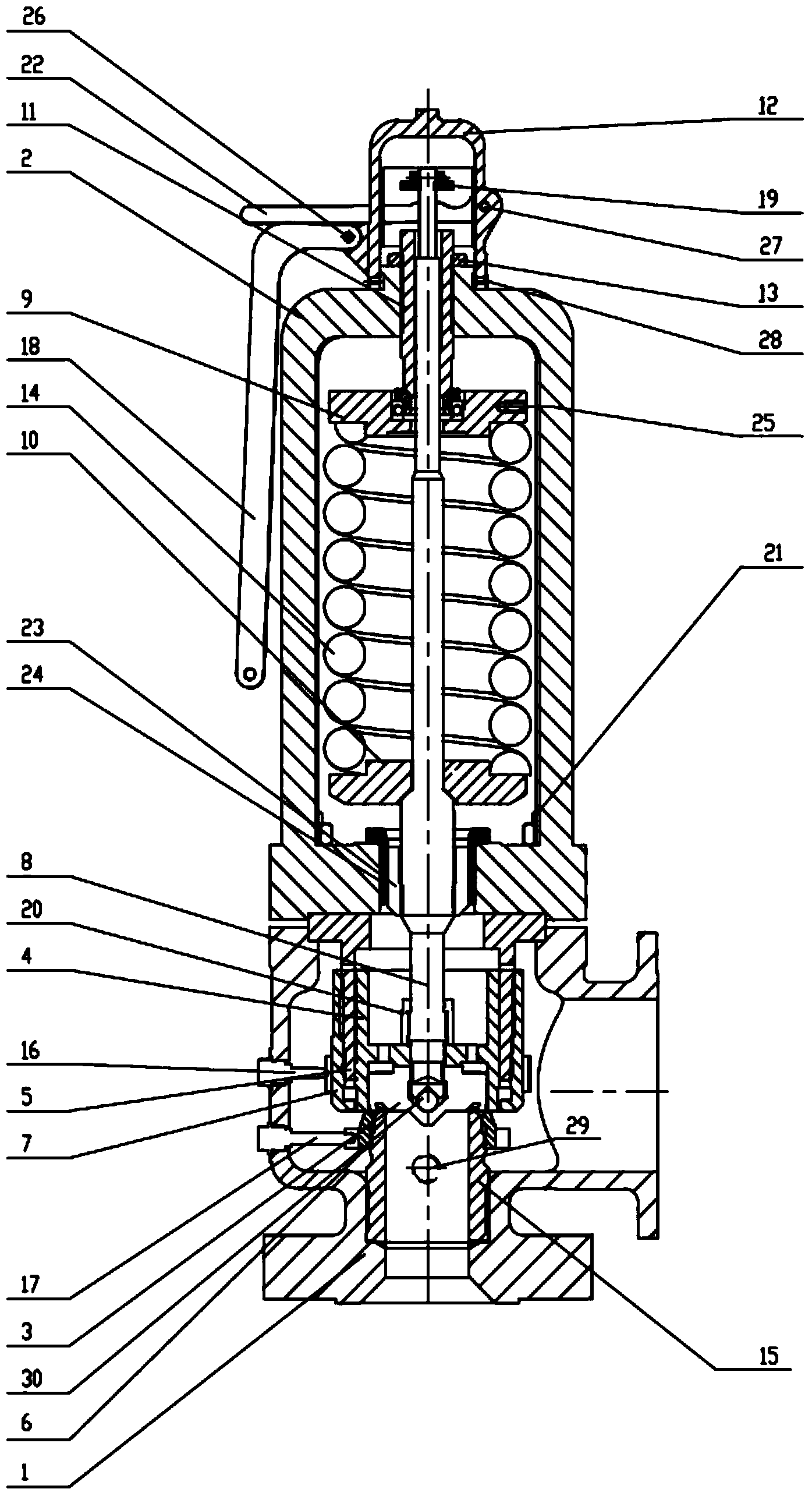

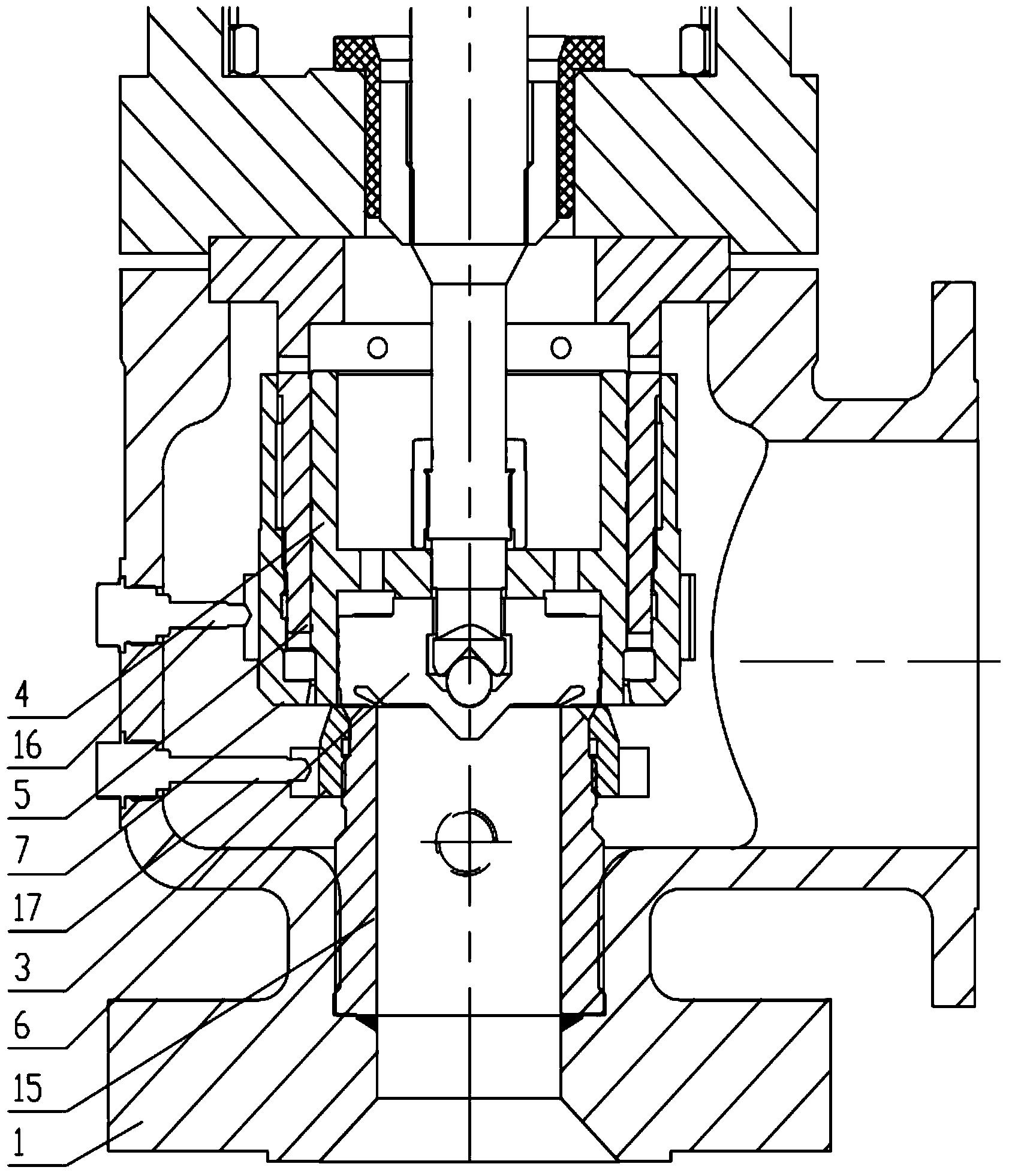

[0022] The stem sealing type closed back pressure regulating steam safety valve according to the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

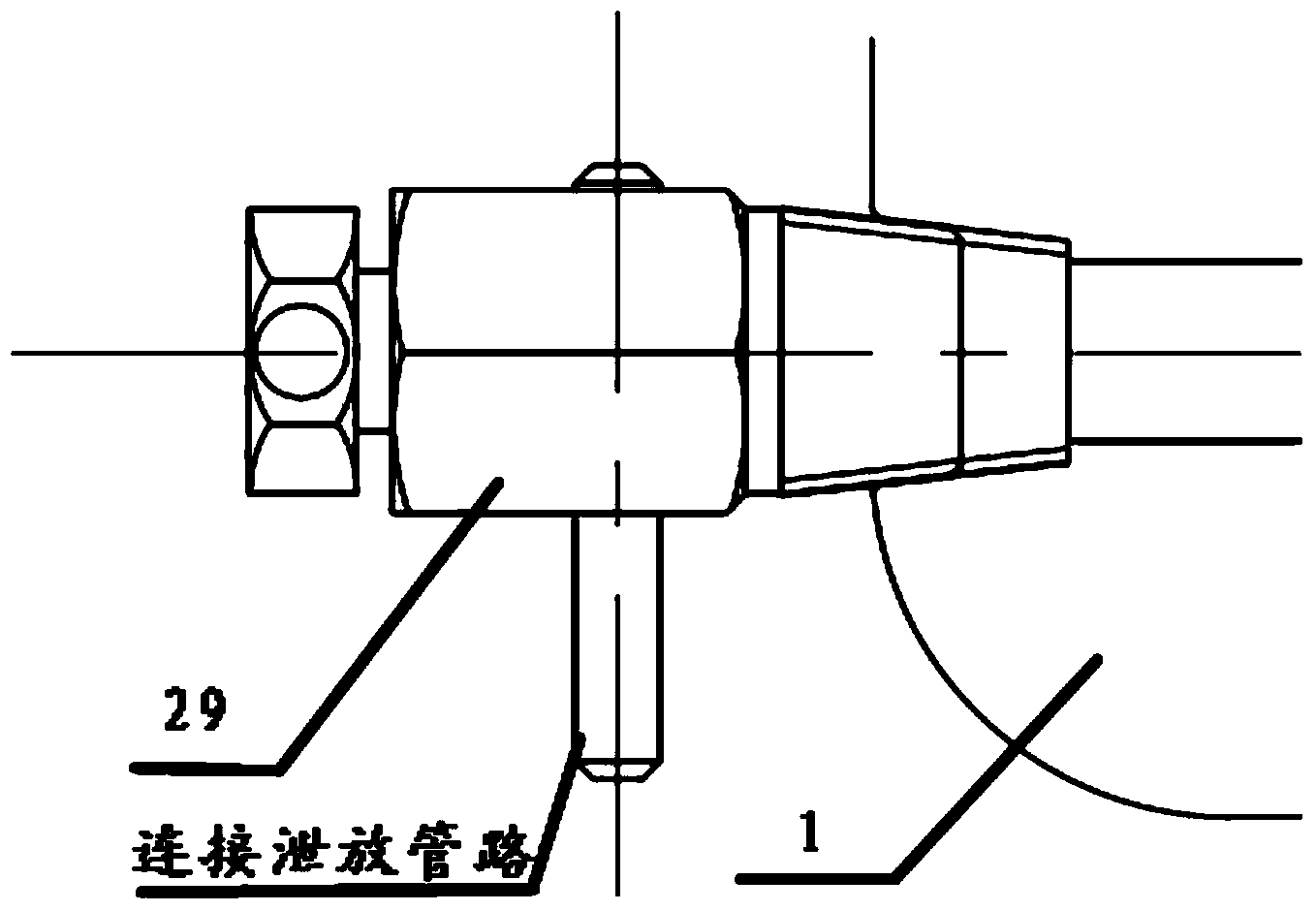

[0023] Such as figure 1 with figure 2 As shown, a stem-sealed closed back pressure regulating steam safety valve according to the present invention includes valve seat 15, valve body 1, valve cover 2 and other components, which can be opened accurately, fully opened in time, and returned in time. Seat, at the same time has excellent seat sealing, the medium is not directly discharged to the outside.

[0024] The lower inlet of the valve body 1 is connected to the protected pressure system through a flange. The valve seat 15 is connected with the valve body 1 by threads and welded as a whole. The valve disc 3 with a cavity inside is installed under the bushing 4 and the collar 20 , and the valve stem 8 is pressed on the valve seat 15 through the steel ball 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com