Treating method for phosphoric waste water and sludge generated in production process of phosphatic compound fertilizer

A technology of production process and treatment method, applied in neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

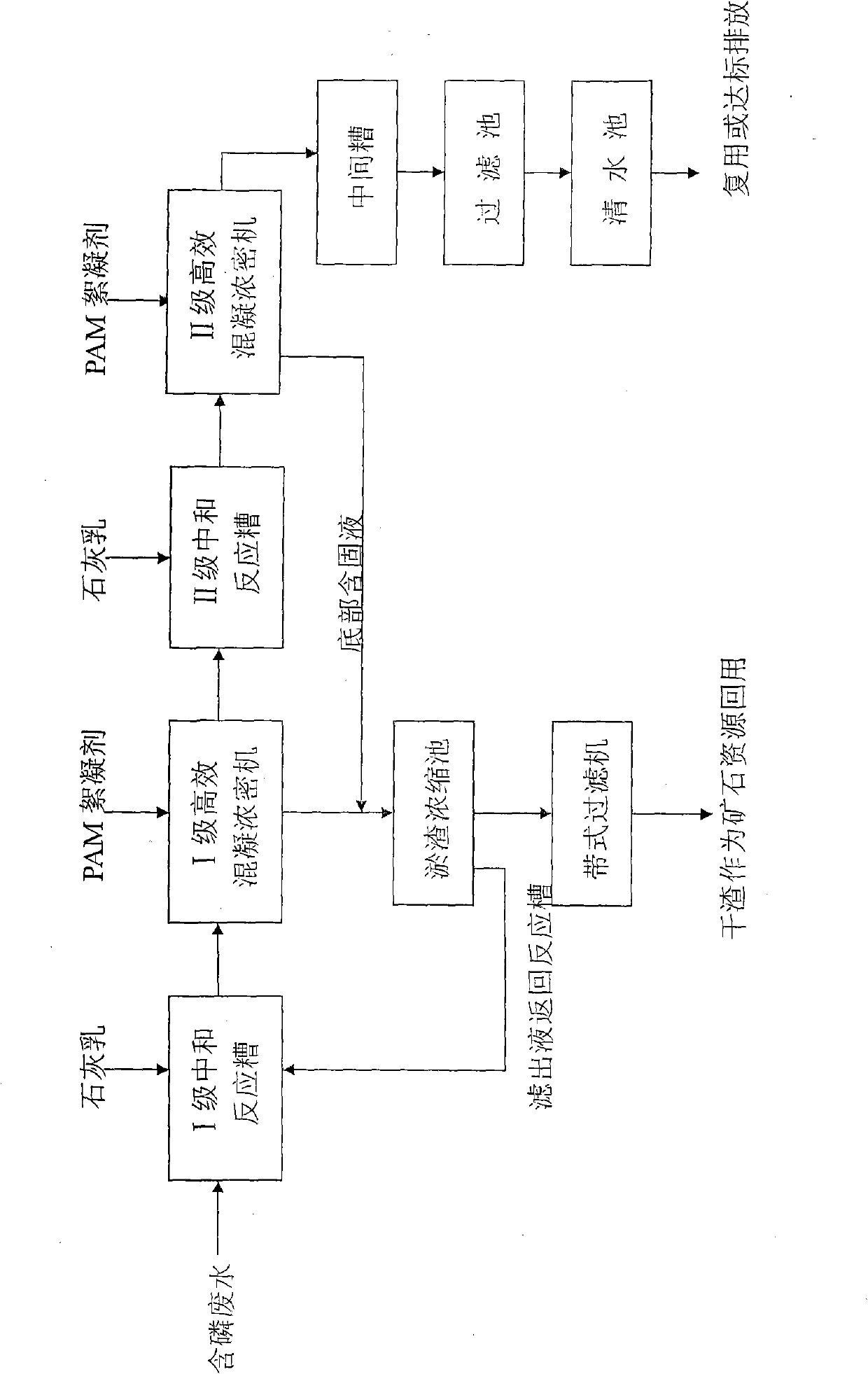

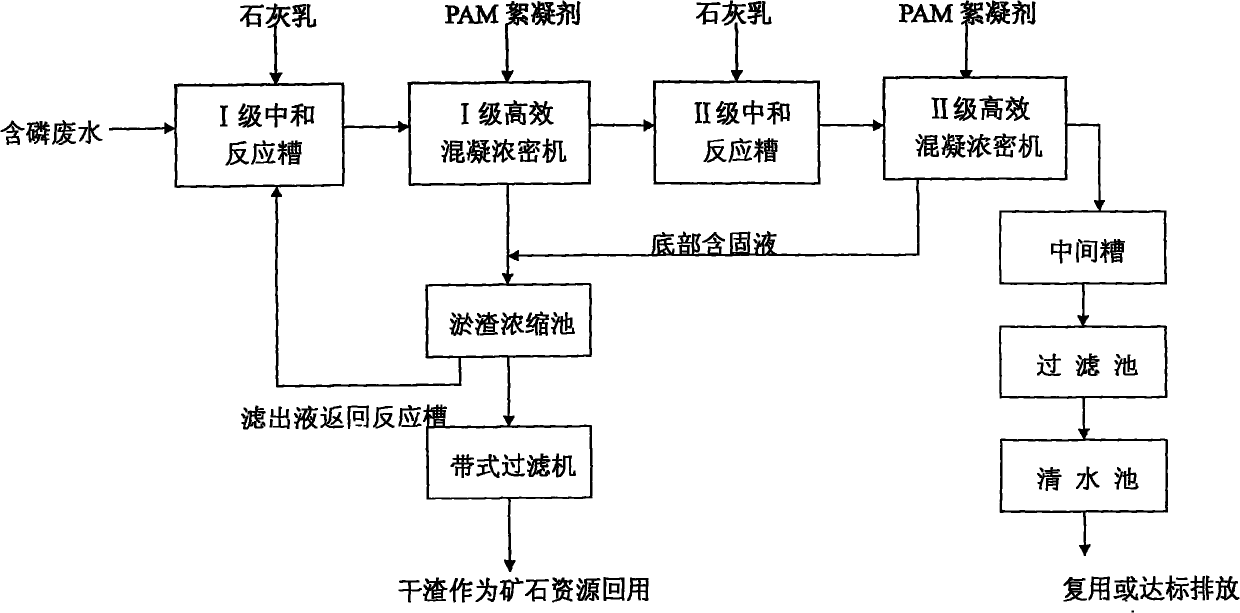

Method used

Image

Examples

Embodiment 1

[0028] (1) After the phosphorus-containing wastewater is measured, it is pumped into the first-stage neutralization reaction tank, and the wastewater is sampled to measure the molar amount of fluorine and phosphorus ions, and then calculate the amount of lime milk input. Add neutralizing agent lime milk, control the pH value in the tank to 5, control the stirring speed of the airflow to 5L / min, make the wastewater appear milky, and fully react for 30 minutes; (2) Add PAM flocculant to the first-level neutralization reaction slurry, The mixed solution is pumped into the I-level high-efficiency coagulation and dense sedimentation machine; (3) The upper clear night overflows into the II-level neutralization reaction tank, and the neutralizer lime milk is put in, and the pH value is controlled to be 10. Fully react for 25 minutes, and the bottom flow contains solid-liquid Go to the sludge concentration tank, and after concentration, go to the belt filter for pressure filtration; (4...

Embodiment 2

[0030] (1) After the phosphorus-containing wastewater is measured, it is pumped into the first-stage neutralization reaction tank, and the wastewater is sampled to measure the molar amount of fluorine and phosphorus ions, and then calculate the amount of lime milk input. Add the neutralizing agent lime milk, control the pH value in the tank to 6, control the stirring speed of the airflow to 5L / min, make the wastewater appear milky, and fully react for 250min; (2) Add PAM flocculant to the first-level neutralization reaction slurry, The mixed solution is pumped into the I-level high-efficiency coagulation and dense sedimentation machine; (3) The upper clear night overflows into the II-level neutralization reaction tank, and the neutralizer lime milk is added in proportion to control the pH value of 11, fully reacted for 20 minutes, and the bottom flow contains Solid-liquid desludge concentration tank, after concentration, go to the belt filter for pressure filtration; (4) Add PA...

Embodiment 3

[0032](1) After the phosphorus-containing wastewater is measured, it is pumped into the first-stage neutralization reaction tank, and the wastewater is sampled to measure the molar amount of fluorine and phosphorus ions, and then calculate the amount of lime milk input. Add neutralizing agent milk of lime earlier, add-on is 70% of total amount, pH value 6 is controlled in the tank, and air flow stirring speed is controlled to be 5L / min, makes waste water be milky, fully reacts 25min; Fully reacts 28min; (2 ) Add PAM flocculant to the first-level neutralization reaction slurry, and the mixed solution is pumped into the first-level high-efficiency coagulation and dense sedimentation machine; (3) the upper clear night overflows into the second-level neutralization reaction tank, and then adds the remaining 30% A large amount of neutralizing agent lime milk, control the pH value of 11, fully react for 22min, the bottom flow contains solid liquid to go to the sludge concentration ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com