Air separation method utilizing liquefied natural gas cold energy

A technology for the separation of liquefied natural gas and air, applied in the direction of cold treatment separation, liquefaction, refrigeration and liquefaction, etc., can solve the problems of high unit energy consumption, underutilization of high-temperature cold energy, high shaft power of raw material air compressors, etc., and achieve unit power consumption Reduced, obvious social and economic benefits, the effect of saving cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

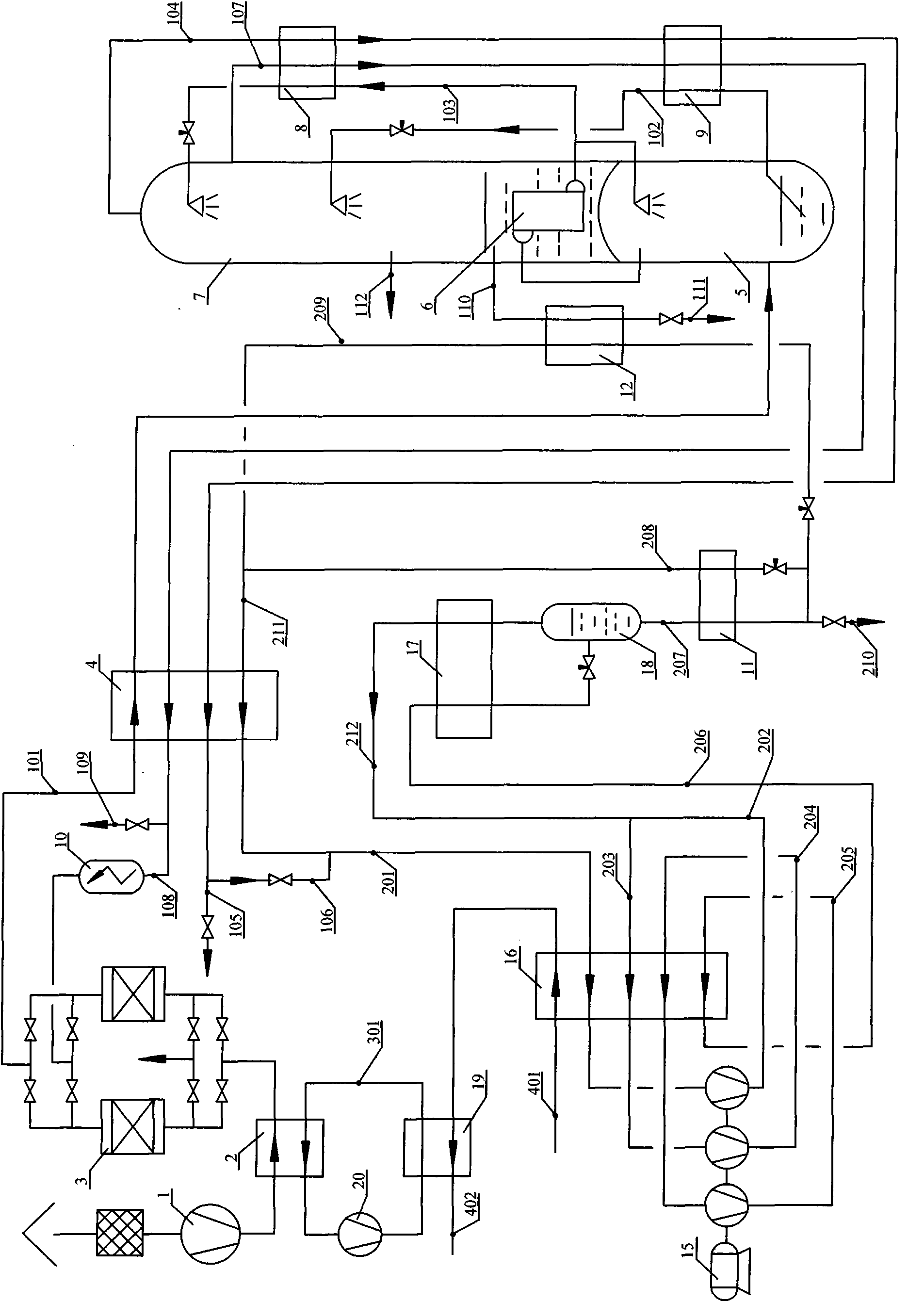

[0034] Such as figure 1 As shown, the air 101 sucked from the atmospheric air through the filter reaches the required pressure of about 0.5Mpa through multi-stage compression (intercooler is cooled with ethylene glycol aqueous solution), and then cools down with ethylene glycol aqueous solution in the final cooler 2, and then Into the air purification system 3 to remove carbon dioxide, water, acetylene and other harmful impurities and then sent to the main cold box of the air separation unit. The purified air is sent to the lower tower 5 after the main heat exchanger 4 exchanges heat with the reflux gas and cools down to the required temperature. The air is preliminarily separated in the lower tower 5 to obtain oxygen-enriched liquid air 102 at the bottom and pure nitrogen at the top. The pure nitrogen enters the main condensing evaporator 6, where it is condensed into liquid nitrogen by liquid oxygen. A part of the liquid nitrogen is sent back to the lower tower to maintain...

Embodiment 2

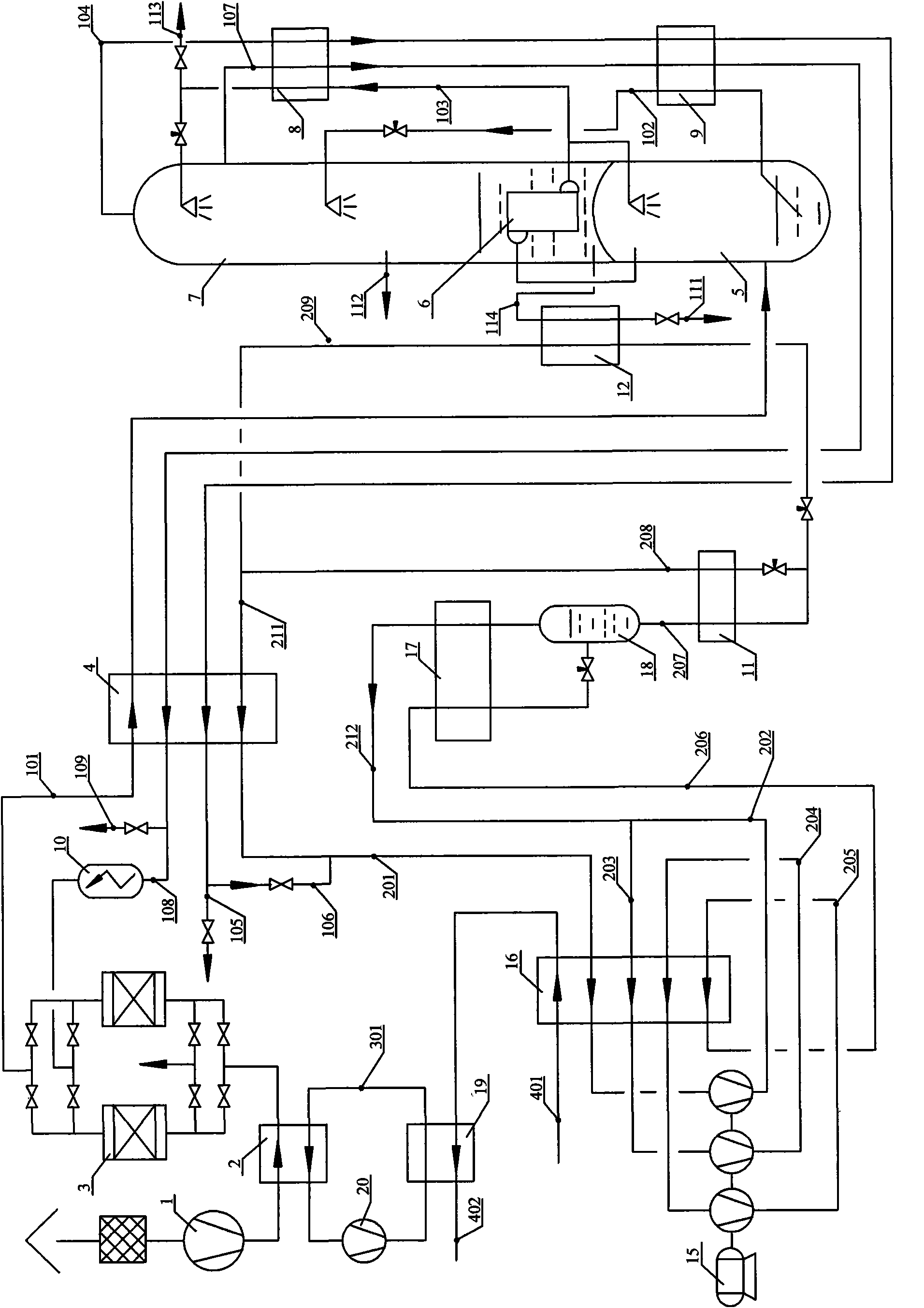

[0039] Such as figure 2 As shown, the difference from Example 1 is mainly that liquid oxygen and liquid nitrogen products are produced by rectification. The refrigerant liquid nitrogen 207 used to transfer the cold energy of LNG is further subcooled and divided into two paths: one path is throttled to a low pressure to supercool itself, and the other path is throttled to supercool the liquid oxygen 114 extracted from the bottom of the upper tower 7 . The low-pressure nitrogen-gas-liquid mixture 208 and 209 are combined to form a low-pressure gas 211 , and the feed air 101 is partially condensed in the main heat exchanger 4 . The raw material air 101 enters the lower tower 5 after being partially condensed, and the liquid nitrogen 103 extracted from the main condensing evaporator after being rectified by the lower tower 5 and the upper tower 7 is sent to the upper tower through throttling after being supercooled by the liquid nitrogen subcooler 8 7. The top part participates ...

Embodiment 3

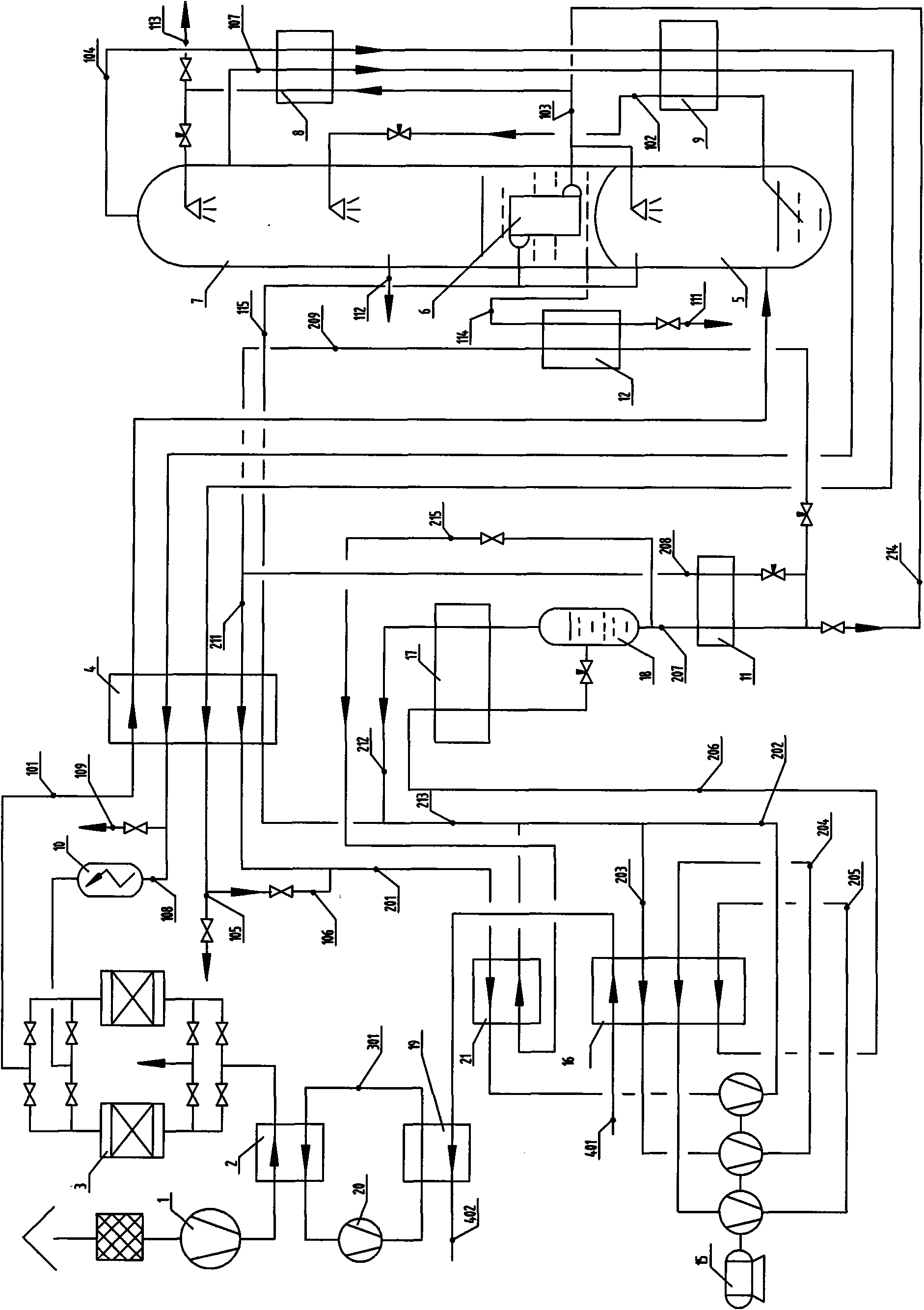

[0044] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is: after ensuring that LNG will not leak into the refrigerant liquid nitrogen 207 that exchanges heat with it, one path of liquid nitrogen 214 can be separated from the refrigerant liquid nitrogen 207 and the main condensation and evaporation The liquid nitrogen 103 in the container 6 is combined, and after cooling, a small part becomes the liquid nitrogen product 113, most of which enter the top of the upper tower 7 to participate in rectification, and provide the required cooling capacity for the separation process. At this time, what is extracted from the bottom of the upper tower 7 is liquid oxygen 114 . In addition, a stream of nitrogen gas 115 is drawn from the top of the lower tower 5 to the main heat exchanger 4 . The medium-pressure nitrogen 115 merges with the medium-pressure nitrogen 212 to form the medium-pressure nitrogen 213 after reheating in the main heat exchanger 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com