Method for combining electrolytic manganese metal waste residues and gypsum to produce cement clinker and ammonium hydroxide

A technology of electrolytic manganese metal and waste slag, applied in the direction of solid waste removal, etc., can solve the problems of excessive magnesium content in cement clinker, affecting water balance, waste of resources, etc., and achieve the goal of recycling, reducing emissions, and reducing construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

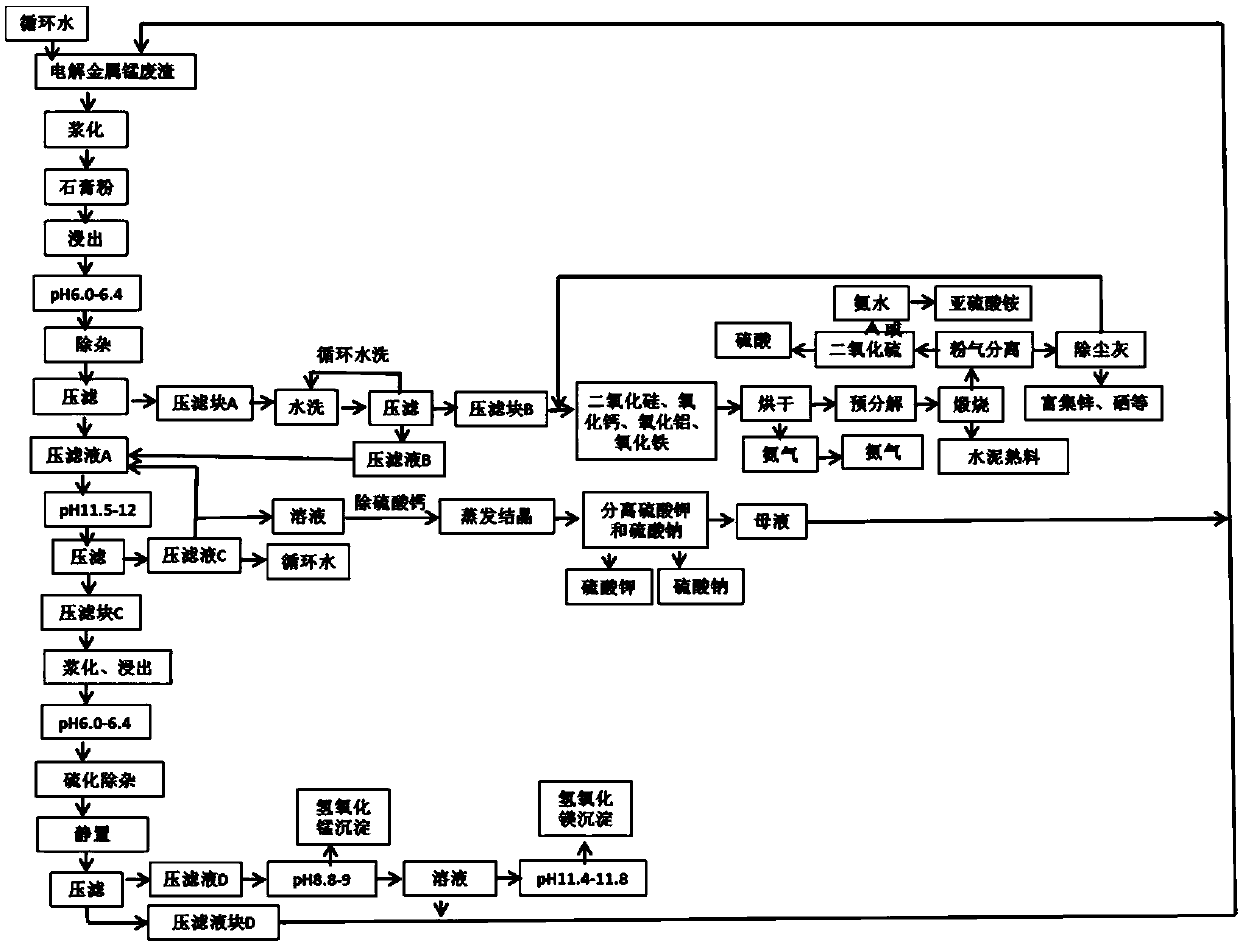

[0049] according to figure 1 The process flow shown is for treating electrolytic manganese metal waste slag, and the specific steps are:

[0050] A. Gypsum is ground into 200-mesh powder to obtain gypsum powder;

[0051] B. Dissolve industrial-grade ammonium sulfate (ammonium sulfate meeting the standard of qualified products in "GB535-1995 Ammonium Sulfate") in water to prepare ammonium sulfate solution;

[0052] C. Detect the content of manganese in the waste residue by electrolytic manganese metal waste residue (according to "GB / T 8654.7-1988 Metal Manganese Chemical Analysis Method Potentiometric Titration Determination of Manganese Content", the content of manganese measured is 6.7%; according to "GB / T In the determination of calcium oxide in 176-2017 "Cement Chemical Analysis Method", the potassium permanganate titration method was used to detect the content of calcium oxide in the waste residue, and the measured calcium oxide content was 14.7%; according to "GB / T176-20...

Embodiment 2

[0058] according to figure 1 The process flow shown is for treating electrolytic manganese metal waste slag, and the specific steps are:

[0059] A. Gypsum is dried and ground into 200-mesh powder to obtain gypsum powder;

[0060] B. Dissolve industrial-grade ammonium sulfate (ammonium sulfate meeting the standard of qualified products in "GB535-1995 Ammonium Sulfate") in water to prepare ammonium sulfate solution;

[0061] C. Detect the manganese content in the electrolytic manganese metal waste residue (according to "GB / T 8654.7-1988 Metal Manganese Chemical Analysis Method Potentiometric Titration Determination of Manganese Content", the manganese content in the waste residue is 7.4%; according to "GB / T 176-2017 "Cement Chemical Analysis Method" in the determination of calcium oxide in the potassium permanganate titration method to detect the content of calcium oxide in the waste residue, the measured calcium oxide content is 12.3%; according to "GB / T176-2008 Cement Chemic...

Embodiment 3

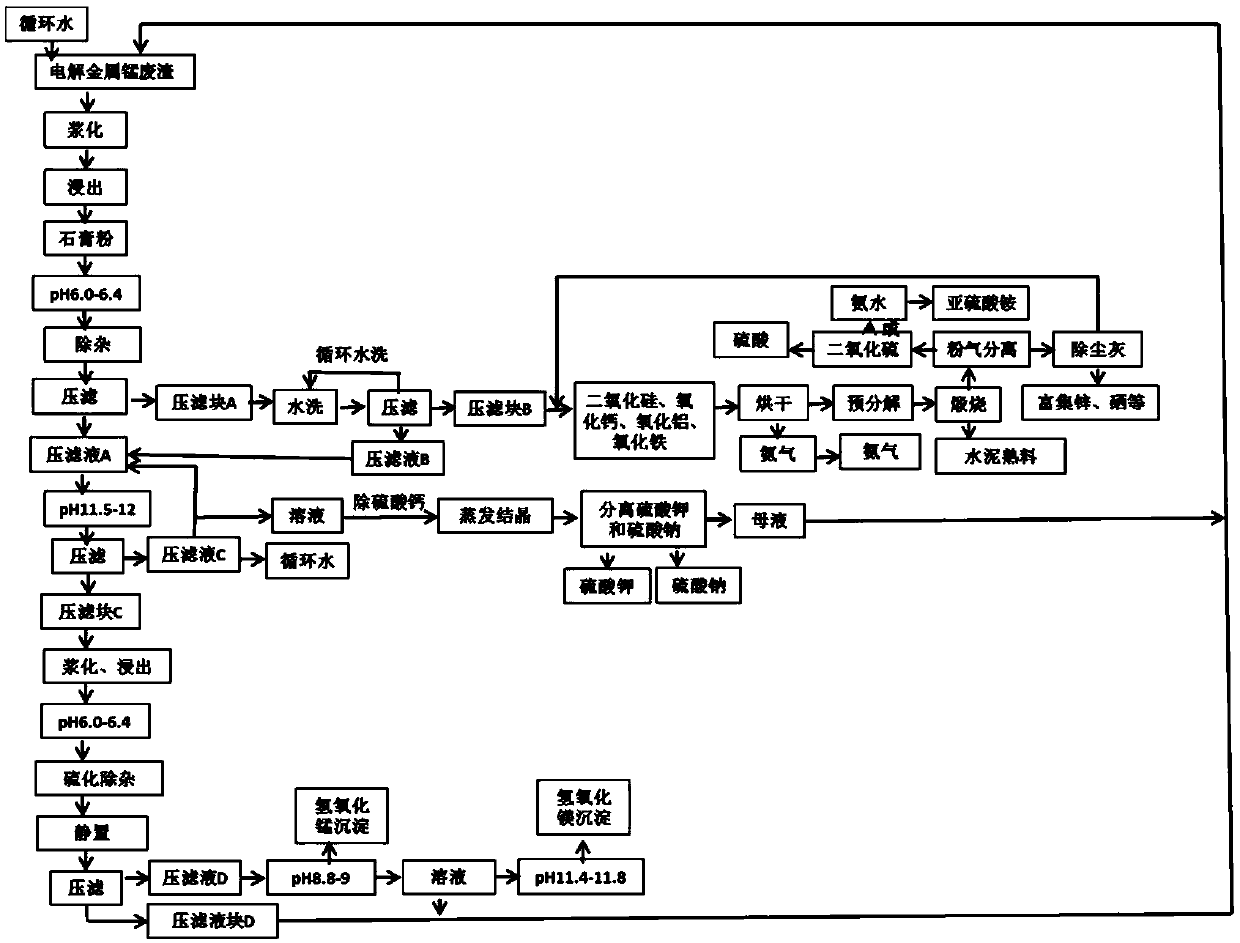

[0067] according to figure 2 The process flow shown is for treating electrolytic manganese metal waste slag, and the specific steps are:

[0068] A. Grinding raw gypsum into 180-mesh powder to obtain gypsum powder;

[0069] B. Dissolve industrial-grade ammonium sulfate (ammonium sulfate meeting the standard of qualified products in "GB535-1995 Ammonium Sulfate") in water to prepare ammonium sulfate solution;

[0070] C. Detect the content of manganese in the waste residue by electrolytic manganese metal waste residue (according to "GB / T 8654.7-1988 Metal Manganese Chemical Analysis Method Potentiometric Titration Determination of Manganese Amount", the measured manganese content is 5.9%; according to "GB / T 176-2017 "Cement Chemical Analysis Methods" in the determination of calcium oxide in the potassium permanganate titration method to detect the content of calcium oxide in the waste residue, the measured calcium oxide content is 11.9%; according to "GB / T176-2008 Cement Chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com