Heat-conducting anti-flaming liquid silicon rubber and preparation method thereof

A technology of liquid silicone rubber and polysiloxane, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of high vulcanization temperature, large smoke generation, power consumption, etc., and achieve good storage stability and vulcanization The effect of high speed and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

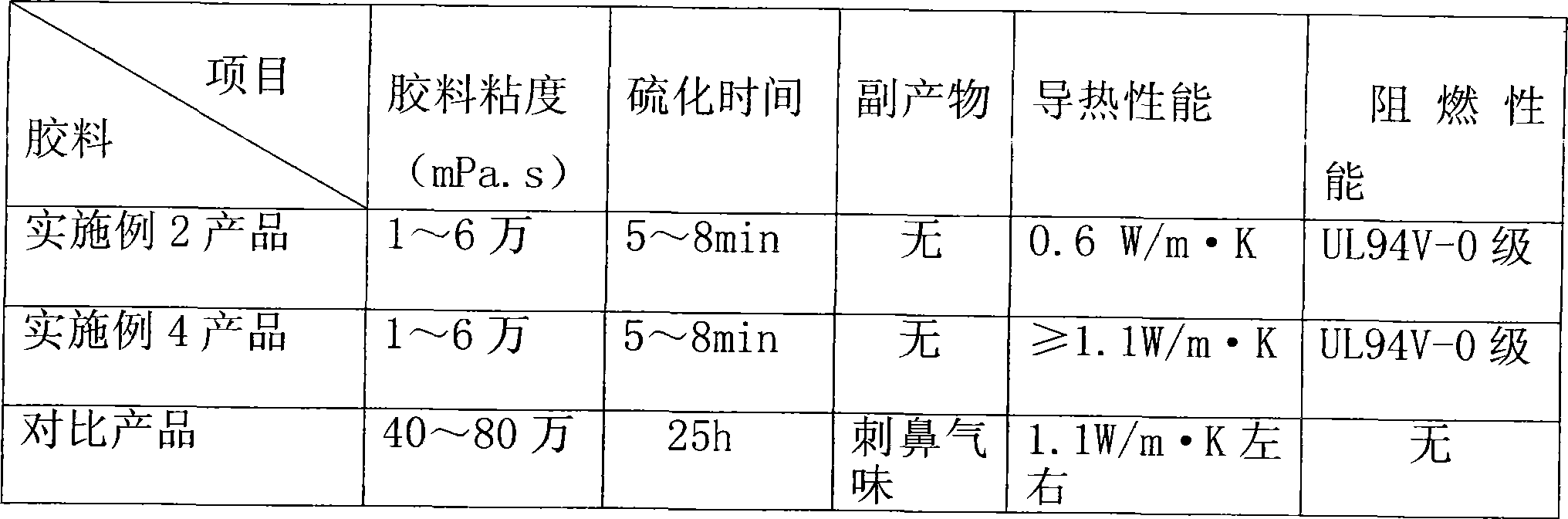

Examples

Embodiment 1

[0042] Embodiment 1: A kind of heat-conducting flame-retardant liquid silicone rubber, its preparation steps are as follows:

[0043] a) Add 10Kg of vinyl-terminated polydimethylsiloxane with a polymerization viscosity of 500-5000mPa.s and 10Kg of vinyl-terminated polydimethylsiloxane with a polymerization viscosity of 10000-50000mPa.s into the kneader at 25°C base siloxane, 2Kg hexamethyldisilazane, 0.5Kg distilled water and 0.01Kg white powder, knead evenly;

[0044] b), mixing 20Kg of Al with a particle size of 5 microns 2 o 3 Powder and 10Kg of Al(OH) with a particle size of 5 microns 3 Powder, add to the kneader in batches, with an interval of no less than 5 minutes each time, knead into a dough and continue kneading at room temperature for 1 hour;

[0045] c), heating up to 150°C and kneading at a constant temperature for 1 hour;

[0046] d) Vacuum at 150°C and knead for 2 hours at a gauge pressure of 0.08Mpa, stop the vacuum, cool down to 120°C and knead evenly to pre...

Embodiment 2

[0048] Embodiment 2: a kind of heat-conducting flame-retardant liquid silicone rubber, its preparation steps are as follows:

[0049] a) Add 40Kg of vinyl-terminated polydiethylsiloxane with a polymerization viscosity of 500 to 5000mPa.s and 40Kg of vinyl-terminated polypropylene with a polymerization viscosity of 10000 to 50000mPa.s into a kneader at 25°C base siloxane, 5Kg hexamethyldisilazane, 2Kg distilled water and 0.02Kg yellow paste, knead evenly;

[0050] b), mixing 50Kg of Al with a particle size of 20 microns 2 o 3 Powder and 50Kg of Al(OH) with a particle size of 20 microns 3 Powder, add to the kneader in batches, with an interval of no less than 5 minutes each time, knead into a dough and continue kneading at room temperature for 1 hour;

[0051] c), heating up to 150°C and kneading at a constant temperature for 1 hour;

[0052] d) Vacuum at 150°C and knead for 2 hours at a gauge pressure of 0.08Mpa, stop the vacuum, cool down to 120°C and knead evenly to prepa...

Embodiment 3

[0054] Embodiment 3: a kind of heat-conducting flame-retardant liquid silicone rubber, its preparation steps are as follows:

[0055] a) Add 25Kg of vinyl-terminated polydimethylsiloxane with a polymerization viscosity of 500-5000mPa.s and 25Kg of vinyl-terminated polydimethylsiloxane with a polymerization viscosity of 10000-50000mPa.s into the kneader at 25°C base siloxane, 3.5Kg hexamethyldisilazane, 1Kg distilled water and 0.01Kg yellow paste, knead evenly;

[0056] b), mixing 30Kg of Al with a particle size of 10 microns 2 o 3 Powder and 25Kg of Al(OH) with a particle size of 10 microns 3 Powder, add to the kneader in batches, with an interval of no less than 5 minutes each time, knead into a dough and continue kneading at room temperature for 1 hour;

[0057] c), heating up to 150°C and kneading at a constant temperature for 1 hour;

[0058] d) Vacuum at 150°C and knead for 2 hours at a gauge pressure of 0.08Mpa, stop the vacuum, cool down to 120°C and knead evenly to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com