Non-burning permeable brick for steel ladle bottom argon bubbling and preparation process thereof

A bottom-blown argon, breathable brick technology, applied in the field of high-temperature ceramics, can solve the problems of unsatisfactory progress and effect, reduced product corrosion resistance, long production cycle, etc., to improve thermal shock stability and corrosion resistance. , The effect of reducing the firing cost and reducing the line change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

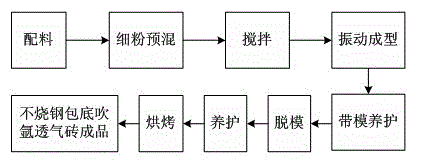

Image

Examples

Embodiment 1

[0024] Non-fired ladle bottom blowing argon ventilation brick, which is composed of the following components and weight: plate corundum 75, spinel 10, a-Al 2 o 3 8. CMA cement 6, pore forming agent 0.5, dispersant 0.5; among them, tabular alumina ensures the high temperature performance and wear resistance of the product; spinel improves the corrosion resistance of the product; a-Al 2 o 3 Make the various components in the product disperse evenly; CMA cement acts as a binder to make the product obtain better strength; by adding a pore-forming agent, ensure the formation of uniform micropores; by adding a dispersant, reduce the production process The amount of water added.

[0025] The plate-shaped corundum is composed of the following components and weight: plate-shaped corundum 25 with a particle size of 3-6 mm, plate-shaped corundum 24 with a particle size of 3-1 mm, plate-shaped corundum 16 with a particle size of 1-0 mm, and a particle size of less than or equal to Tabu...

Embodiment 2

[0037] Non-fired ladle bottom blowing argon permeable brick, which is composed of the following components and weight: tabular corundum 65, spinel 14, a-Al 2 o 3 10. CMA cement 8, pore forming agent 0.8, dispersant 0.8; among them, tabular alumina ensures the high temperature performance and wear resistance of the product; spinel improves the corrosion resistance of the product; a-Al 2 o 3 Make the various components in the product disperse evenly; CMA cement acts as a binder to make the product obtain better strength; by adding a pore-forming agent, ensure the formation of uniform micropores; by adding a dispersant, reduce the production process The amount of water added.

[0038] The tabular alumina is composed of the following components and weight: tabular alumina 20 with a particle size of 3-6 mm, tabular alumina 28 with a particle size of 3-1 mm, tabular alumina 12 with a particle size of 1-0 mm, and a particle size of less than or equal to 0.074mm tabular alumina 5. ...

Embodiment 3

[0050] Non-fired ladle bottom blowing argon ventilation brick, which is composed of the following components and weight: plate corundum 85, spinel 6, a-Al 2 o 35. CMA cement 4, pore forming agent 0.3, dispersant 0.3; among them, tabular alumina ensures the high temperature performance and wear resistance of the product; spinel improves the corrosion resistance of the product; a-Al 2 o 3 Make the various components in the product disperse evenly; CMA cement acts as a binder to make the product obtain better strength; by adding a pore-forming agent, ensure the formation of uniform micropores; by adding a dispersant, reduce the production process The amount of water added.

[0051] The tabular alumina is composed of the following components and weight: tabular alumina 30 with a particle size of 3-6 mm, tabular alumina 20 with a particle size of 3-1 mm, tabular alumina 20 with a particle size of 1-0 mm, and a particle size of less than or equal to Tabular alumina 15 of 0.074mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com