High-strength long-life stopper rod and preparation method thereof

A high-strength, plug-rod technology, used in the field of refractory products, can solve the problems of low strength and short service life of plug-rods, and achieve the effect of enhancing flexural and pressure resistance and improving thermal shock stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

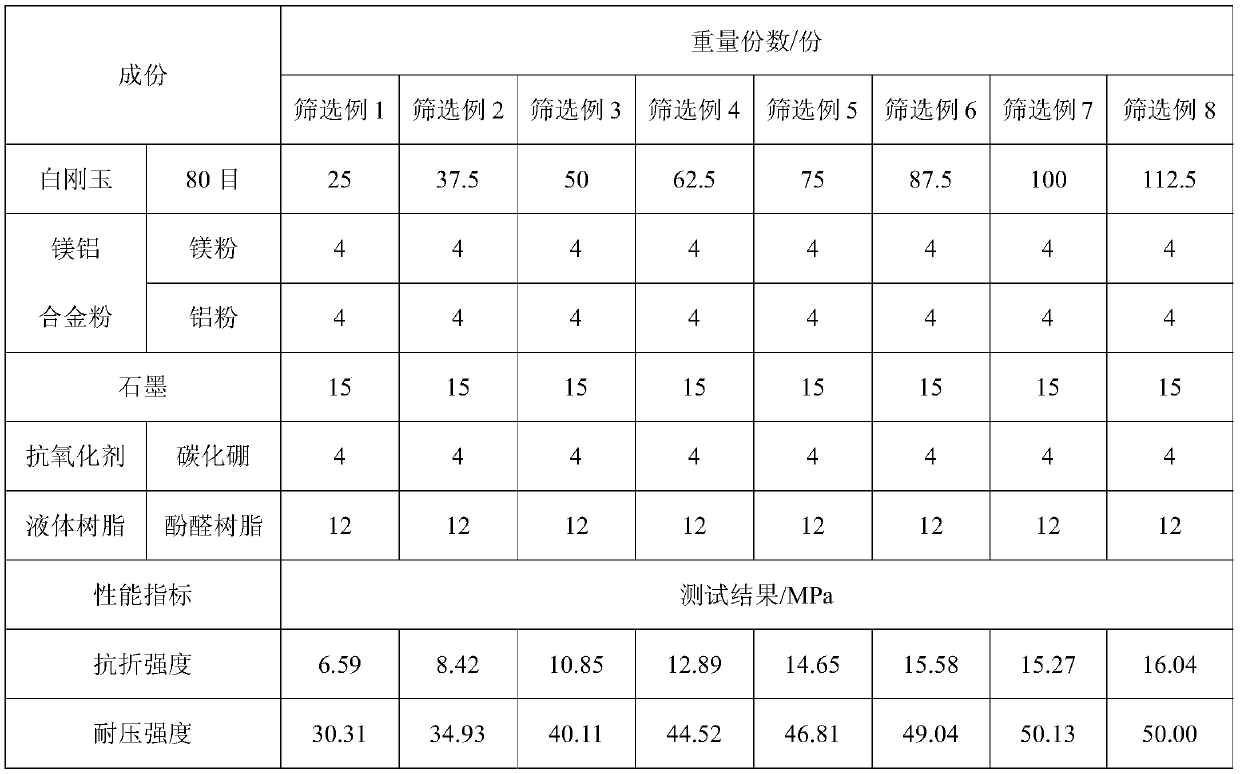

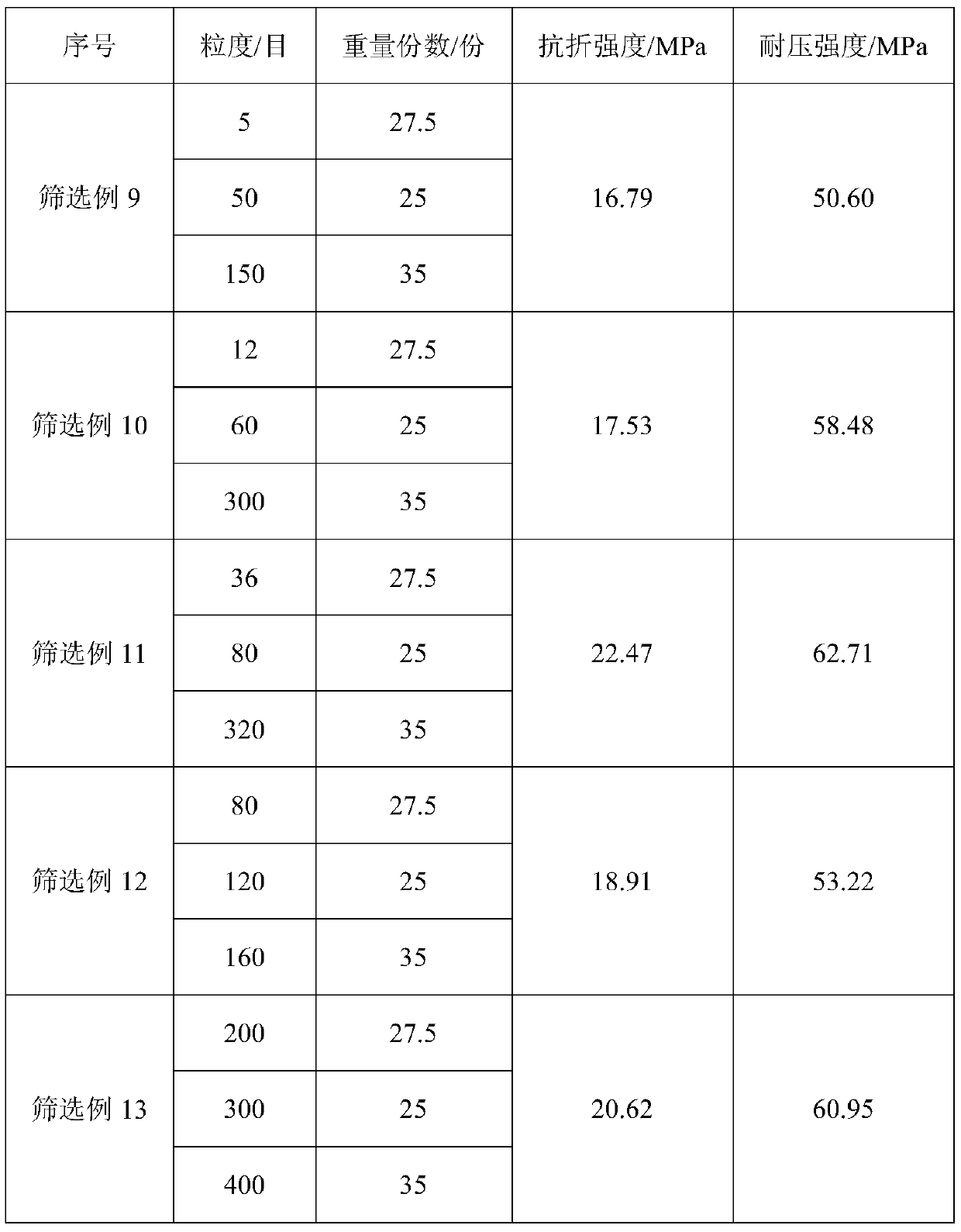

Examples

preparation example Construction

[0032] The preparation method of stopper rod comprises the following steps:

[0033] (1) Add the white corundum, magnesium-aluminum alloy powder, graphite, antioxidant and liquid resin weighed in proportion to the mixer, and stir for 20 minutes to obtain the sludge;

[0034] (2) After drying the stirred mud material for 25 minutes, put it into an airtight container to trap the material;

[0035] (3) Fill the trapped mud into the rubber mould;

[0036] (4) rubber mold is put into the cold isostatic pressing machine, through 80MPa pressure molding, obtain semi-finished product;

[0037] (5) Put the formed semi-finished product into a drying kiln, and dry and solidify at 250°C;

[0038] (6) process the semi-finished product after drying to a regular shape with a lathe and apply one deck of anti-oxidation coating;

[0039] (7) After the paint is completely dry, put the product into a kiln for firing at 1200°C and keep it warm for 10 hours to obtain a finished stopper.

[0040]...

Embodiment 1

[0062] Embodiment 1 A kind of high-strength, high-life stopper rod

[0063] The raw materials of the stopper include 27.5 parts of 36 mesh white corundum, 25 parts of 80 mesh white corundum, 35 parts of 320 mesh white corundum, 7.5 parts of 200 mesh magnesium aluminum alloy powder (magnesium powder: aluminum powder = 1:1), 15 parts of graphite, antioxidant carbonization 4 parts of boron and 12 parts of liquid phenolic resin;

[0064] The preparation method of above-mentioned stopper rod comprises the following steps:

[0065] (1) Add the white corundum, magnesium-aluminum alloy powder, graphite, antioxidant and liquid resin weighed in proportion to the mixer, and stir for 20 minutes to obtain the sludge;

[0066] (2) After drying the stirred mud material for 25 minutes, put it into an airtight container to trap the material;

[0067] (3) Fill the trapped mud into the rubber mould;

[0068] (4) rubber mold is put into the cold isostatic pressing machine, through 80MPa pressu...

Embodiment 2

[0073] Embodiment 2 A kind of high-strength, high-life stopper rod

[0074] The raw materials of the stopper include 22 parts of 36 mesh white corundum, 16 parts of 80 mesh white corundum, 28 parts of 320 mesh white corundum, 6 parts of 200 mesh magnesium aluminum alloy powder (magnesium powder: aluminum powder = 1:1), 17 parts of graphite, antioxidant carbonization 3.5 parts of boron and 14 parts of liquid phenolic resin;

[0075] The preparation method of above-mentioned stopper rod comprises the following steps:

[0076] (1) Add white corundum, magnesium-aluminum alloy powder, graphite, antioxidant and liquid resin weighed in proportion to the mixer, and stir for 25 minutes to obtain mud;

[0077] (2) After drying the stirred mud material for 30 minutes, put it into an airtight container to trap the material;

[0078] (3) Fill the trapped mud into the rubber mould;

[0079] (4) rubber mold is put into cold isostatic pressing machine, through 100MPa pressure molding, obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com