Improvement on non-oxidation firing electric furnace for carbon-containing materials

A non-oxidizing, carbon-free technology, used in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of unenvironmental protection and environmental pollution of firing furnaces, save heating power, expand effective use volume, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

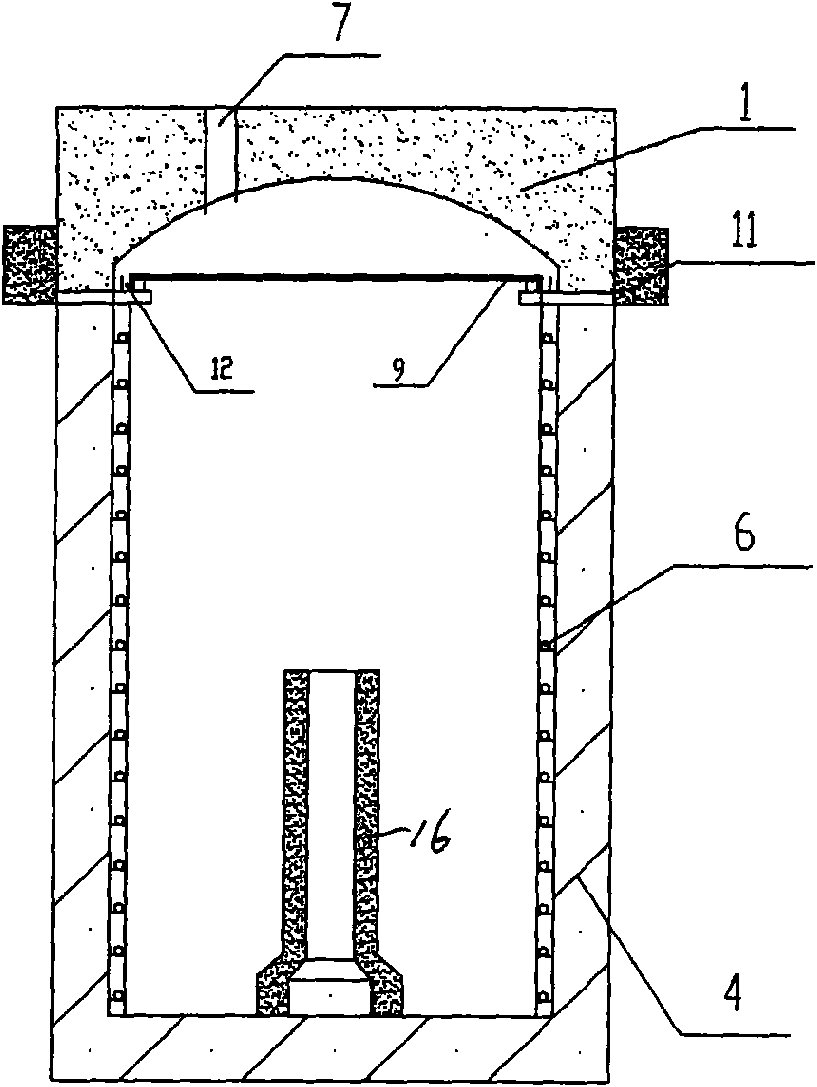

[0027] Example 2: see Figure 4 , as in embodiment 1, the exhaust duct 7 is a metal pipe, and a closed jacket pipe 13 is added outside, and the upper and lower ends have cooling medium inlet and outlet passages respectively, and by passing into a circulating cooling medium, such as cold air or cooling water, rapid Cool down and cool down. By adjusting the cooling rate and cooling capacity, the harmful substances are cooled and returned to the space between the heat preservation furnace cover and the inner cover (there is a collection tank on the top surface of the inner cover) through the discharge pipe 7, and become solid objects as the furnace temperature cools.

Embodiment 3

[0028] Embodiment 3: see Figure 4 , as in embodiment 1 or 2, several cooling tube rings 14 are arranged on the inner wall of the furnace, and after the firing is completed, a circulating cooling medium (such as water or cooling air) is passed into it to realize rapid cooling under sealed conditions. And the floating inner cover can also be set to be fixed, and a one-way pressure discharge valve 15 is arranged on the inner cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com