Energy-saving heat treatment well type heating furnace

An energy-saving, heating furnace technology, used in vertical furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of short service life of the furnace body, high manufacturing cost, poor thermal insulation performance, etc. Good effect, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

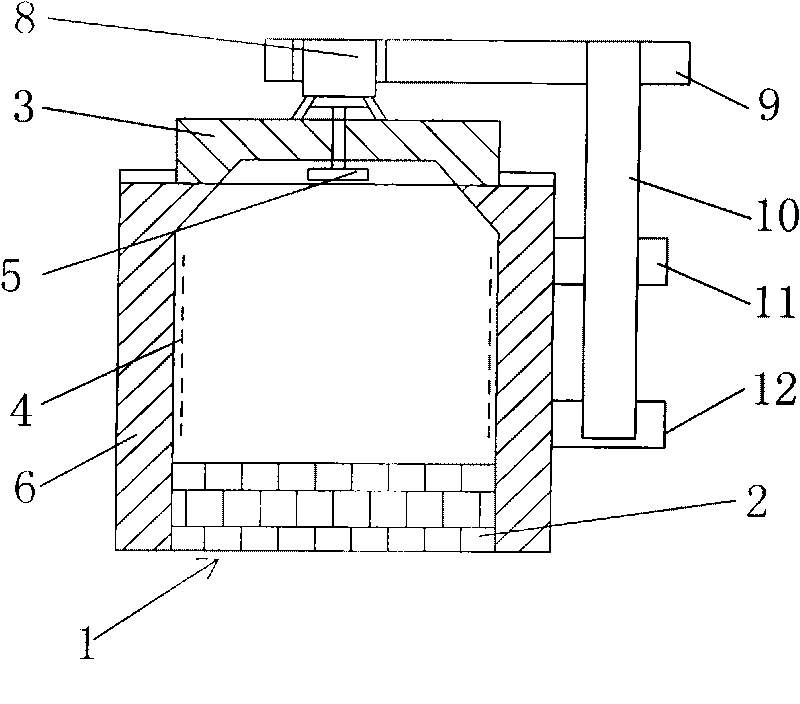

Embodiment 1

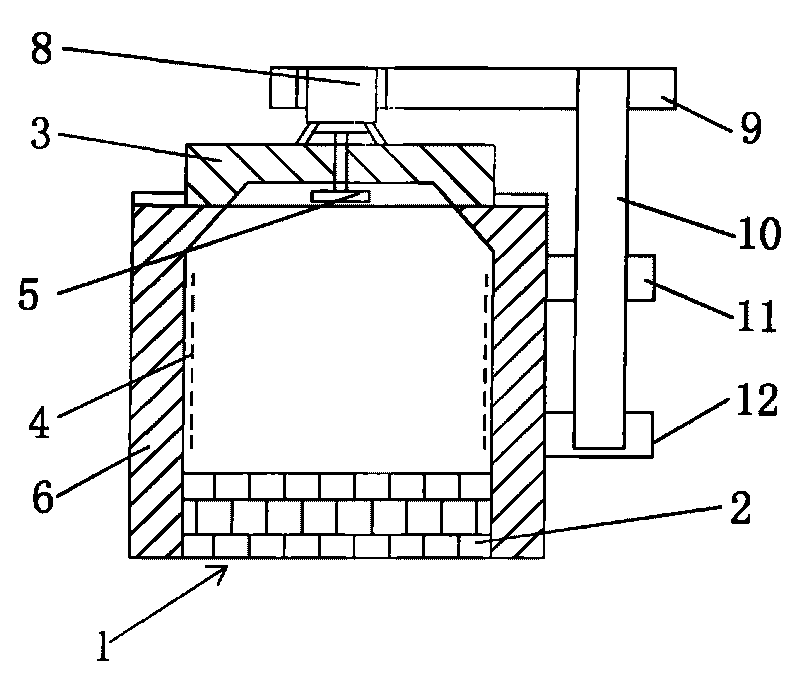

[0014] An energy-saving heat treatment well-type heating furnace includes a furnace body 1, a furnace cover 3, a strip electric heater 4, an electric fan 5 and a furnace cover moving mechanism. Furnace body 1 is composed of aluminum silicate fiber furnace wall 6 and furnace bottom 2 made of refractory bricks. The furnace cover 3 is an aluminum silicate fiber furnace cover, and the furnace cover 3 is buckled on the upper port of the aluminum silicate fiber furnace wall. The strip electric heater 4 is a known electric heater, fixed on the aluminum silicate fiber furnace wall 6 on the inner wall. The electric fan 5 is arranged below the furnace cover 3 , and the fan rotating shaft passes through the furnace cover 3 and is connected with the output shaft of the motor 8 , and the motor 8 is fixed on the furnace cover 3 . The furnace cover moving mechanism includes a furnace cover support plate 9 , a vertical shaft 10 , a first support wall shaft seat 11 and a second support wall s...

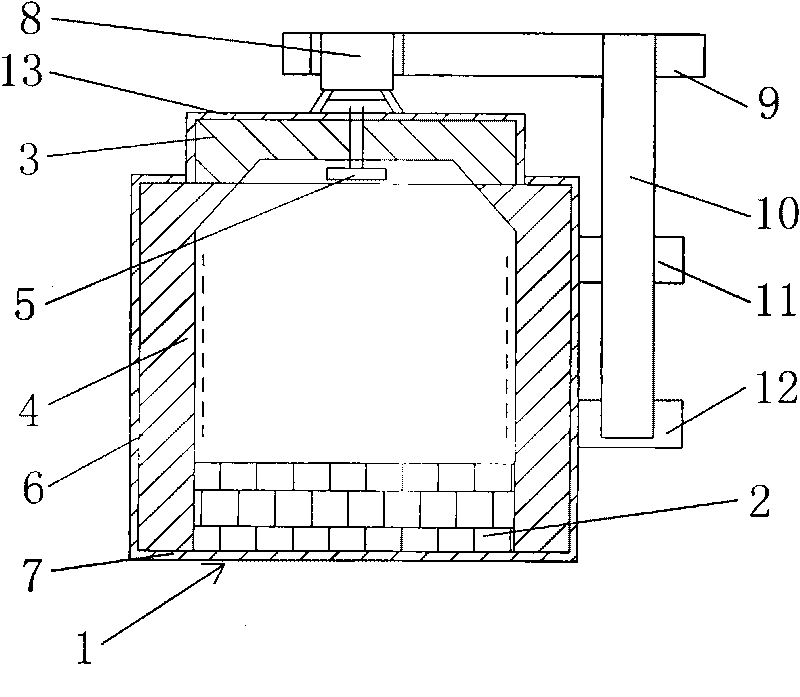

Embodiment 2

[0016] Embodiment two is basically the same as embodiment one in structure, and its difference is:

[0017] The furnace body 1 is fixedly arranged in a furnace shell 7 made of steel, and the outer wall of the furnace cover 3 is fixed with a furnace cover shell 13 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com