A Gradient Tab with Nearly Equal Cross-sectional Area

A cross-sectional area, gradual change technology, applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve the problems of low connection strength, slow heat conduction, difficult sealing, etc., to enhance connection reliability, reduce heat storage, reduce The effect of sealing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

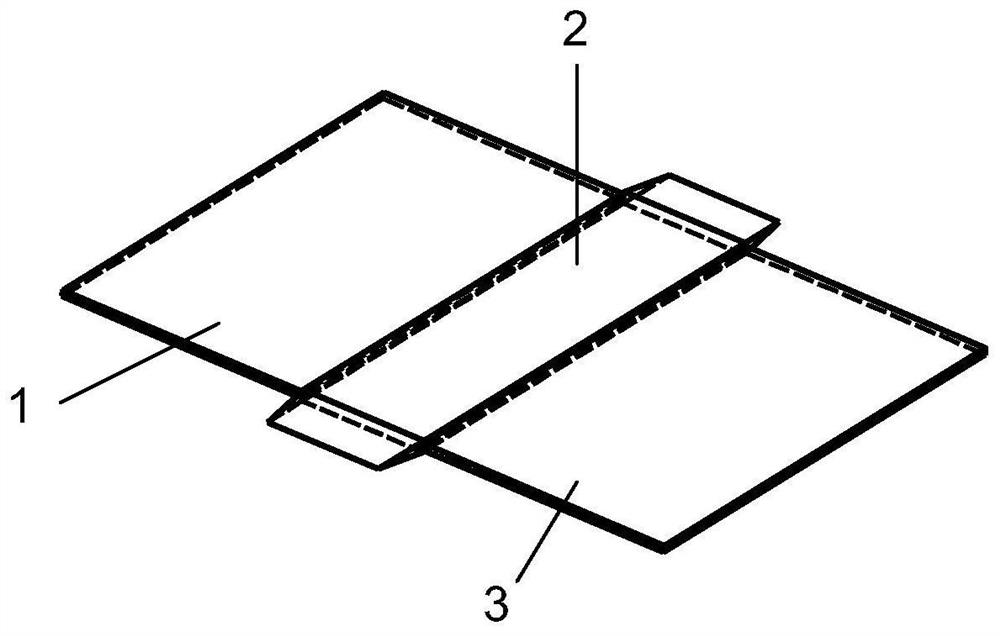

[0035] A near-equal cross-sectional area gradient tab suitable for soft-pack power batteries figure 2 As shown, the lug body adopts a nearly equal cross-section gradient method, the sealing area 2 of the lug body has a small thickness, and the lead-in and outlet ends 1 and 3 of the lug body are pole structures, which have strong machinability. Its specific design is as follows:

[0036] The sealing area 2 is covered with ear glue, the lead-in end 1 is cylindrical, with the smallest surface area, and then gradually changes to a near-equal cross-sectional area until the sealing area 2 is flat plate-shaped, with the largest surface area, and then the near-equal cross-sectional area gradually changes to the lead-out end 3 , the shape is symmetrical to that of the lead-in end 1.

[0037] The lug designed with this shape can effectively reduce the thickness of the tab sealing area 2 , thus allowing greater current density under the same sealing thickness. At the same time, the le...

Embodiment 2

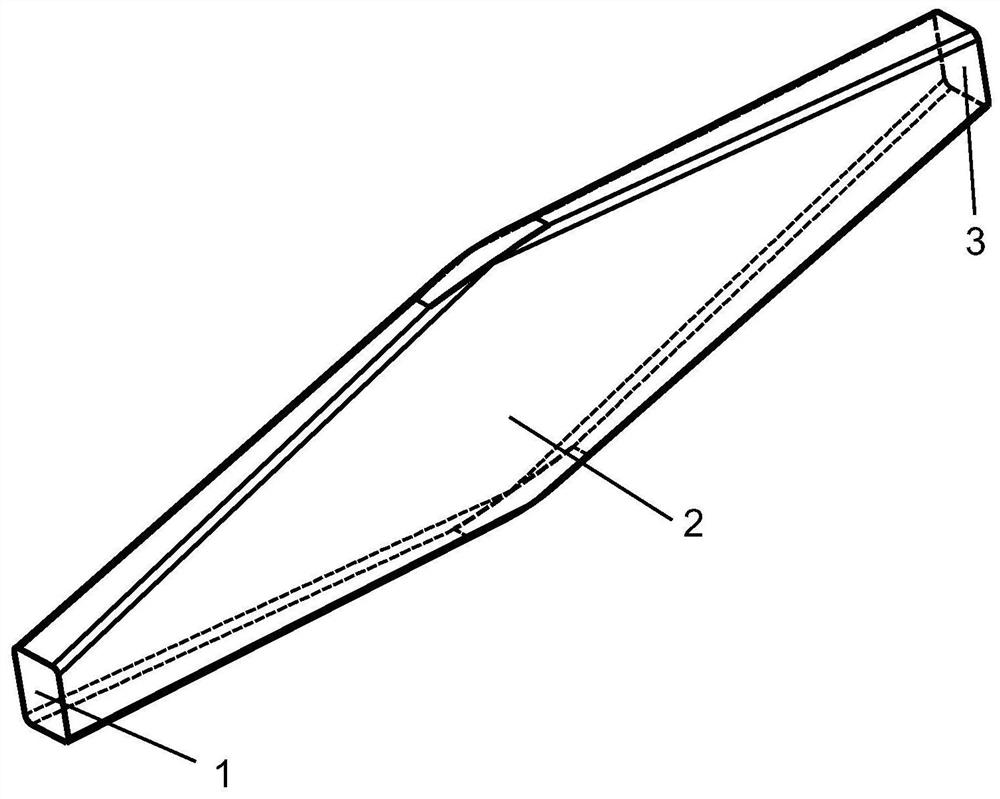

[0039] A near-equal-sectional-area gradient tab that is also suitable for soft-pack power batteries image 3 As shown, the lug body adopts a nearly equal cross-section gradual change method, the sealing area 2 of the lug body has a small surface area, and the surface areas at the inlet and outlet ends 1 and 3 are large. Its specific design is as follows:

[0040] The sealing area 2 is covered with tab glue, the leading-in end 1 is a flat plate with the largest surface area, and then gradually changes to a near-equal cross-sectional area until the sealing area 2 is cylindrical, with the smallest surface area, and then gradually changes to a near-equal cross-sectional area to lead-out At the end 3, the shape is symmetrical with that of the introduction end 1.

[0041] The lug designed with this shape can effectively reduce the surface area of the tab sealing area 2, increase the rate of good sealing products, and reduce the leakage rate of the battery cell. In addition, the ...

Embodiment example 3

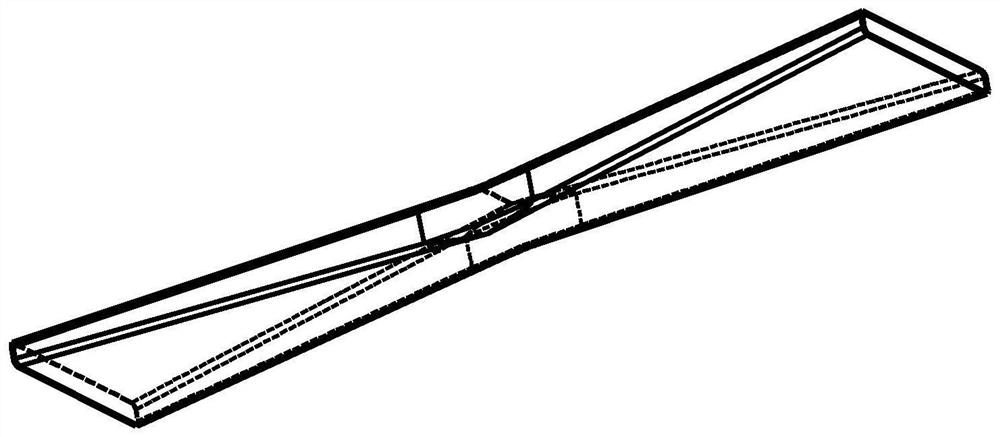

[0043] A near-equal-sectional-area gradient tab that is also suitable for soft-pack power batteries Figure 4 As shown, the lug body adopts a nearly equal cross-sectional area gradual change method, and the sealing area 2 of the lug body has a small surface area and a curved surface. Its specific design is as follows:

[0044] The sealing area 2 is covered with tab glue, and the lead-in end 1 is in the shape of a flat plate with the largest surface area, and then gradually changes to an equal cross-sectional area until the seal area 2 becomes an ellipse, and then changes to an equal cross-sectional area to lead-out end 3 , and the leading end 3 is symmetrical to the leading end 1.

[0045] The lug with this shape design provides a surface arc structure on the basis of Example 2, which can more effectively increase the sealing yield and reduce the proportion of battery cell leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com