Hydraulic pump for excavator, and excavator with same

A technology for excavators and hydraulic pumps, which is applied in the field of hydraulic pumps, and can solve problems such as affecting the efficient operation of hydraulic pumps and excessive vibration of drive shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

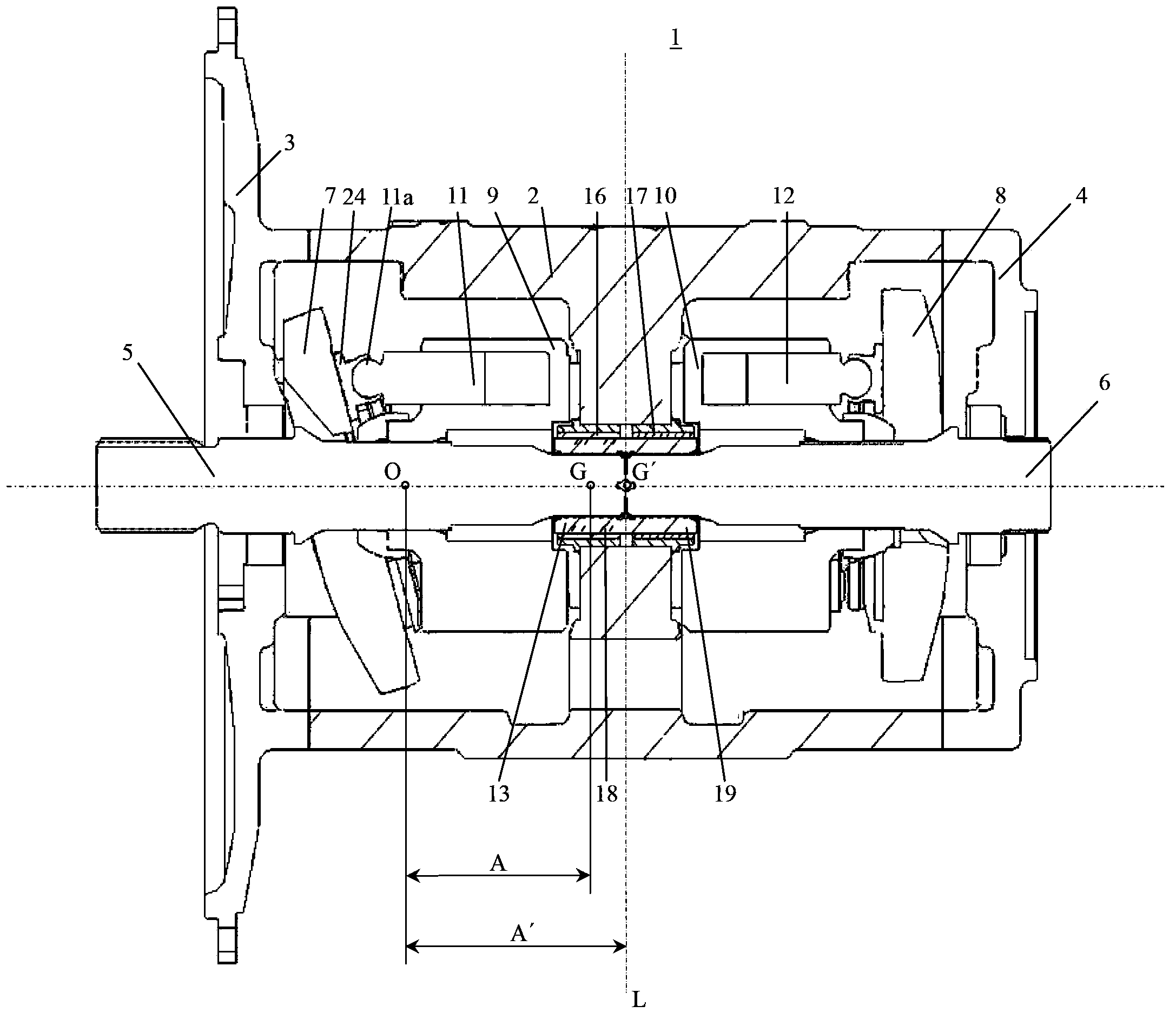

[0023] Illustrative embodiments of the present invention are described below with reference to the accompanying drawings. It should be noted that the same reference numerals in the drawings represent elements or components with the same function and / or structure.

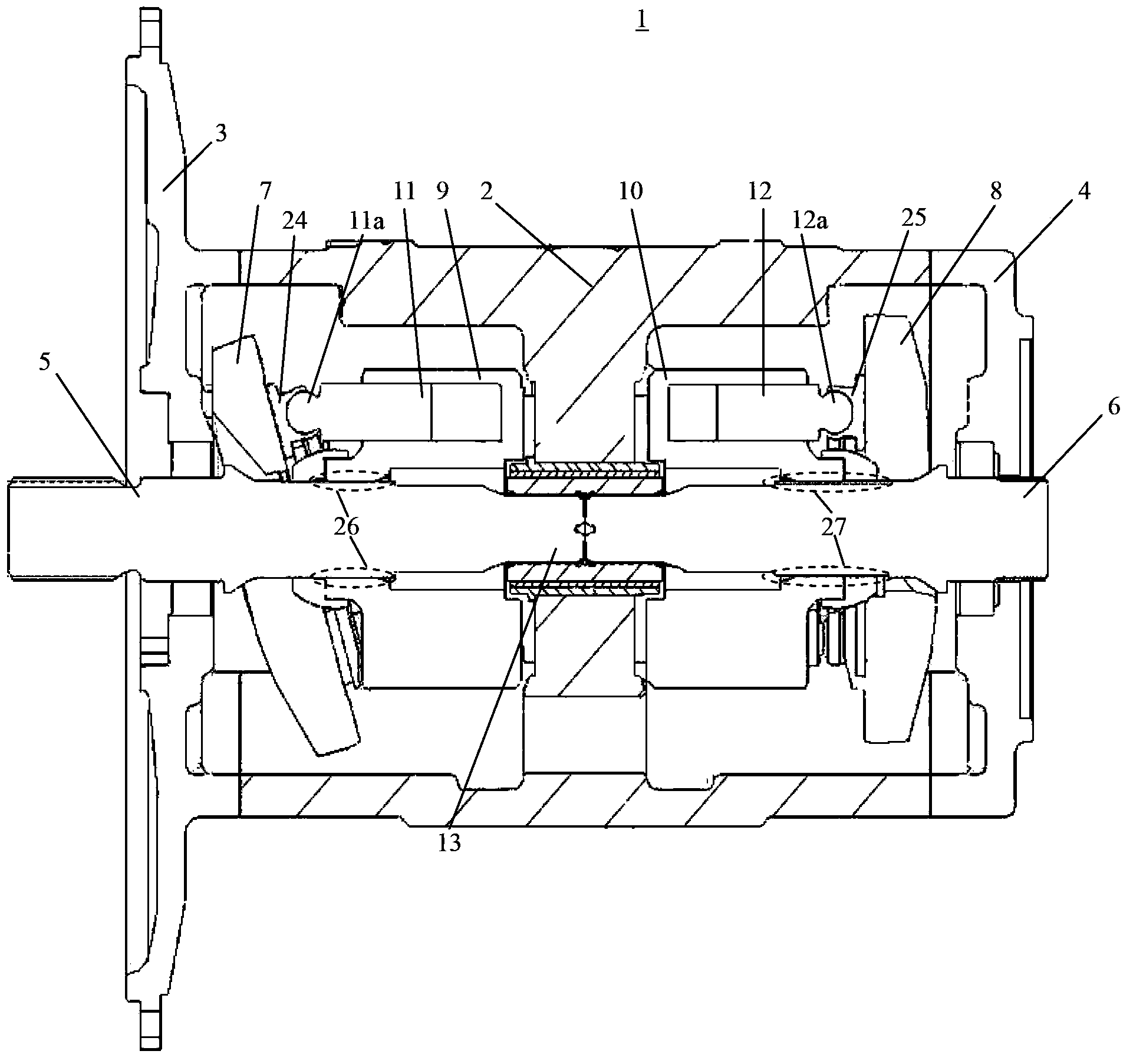

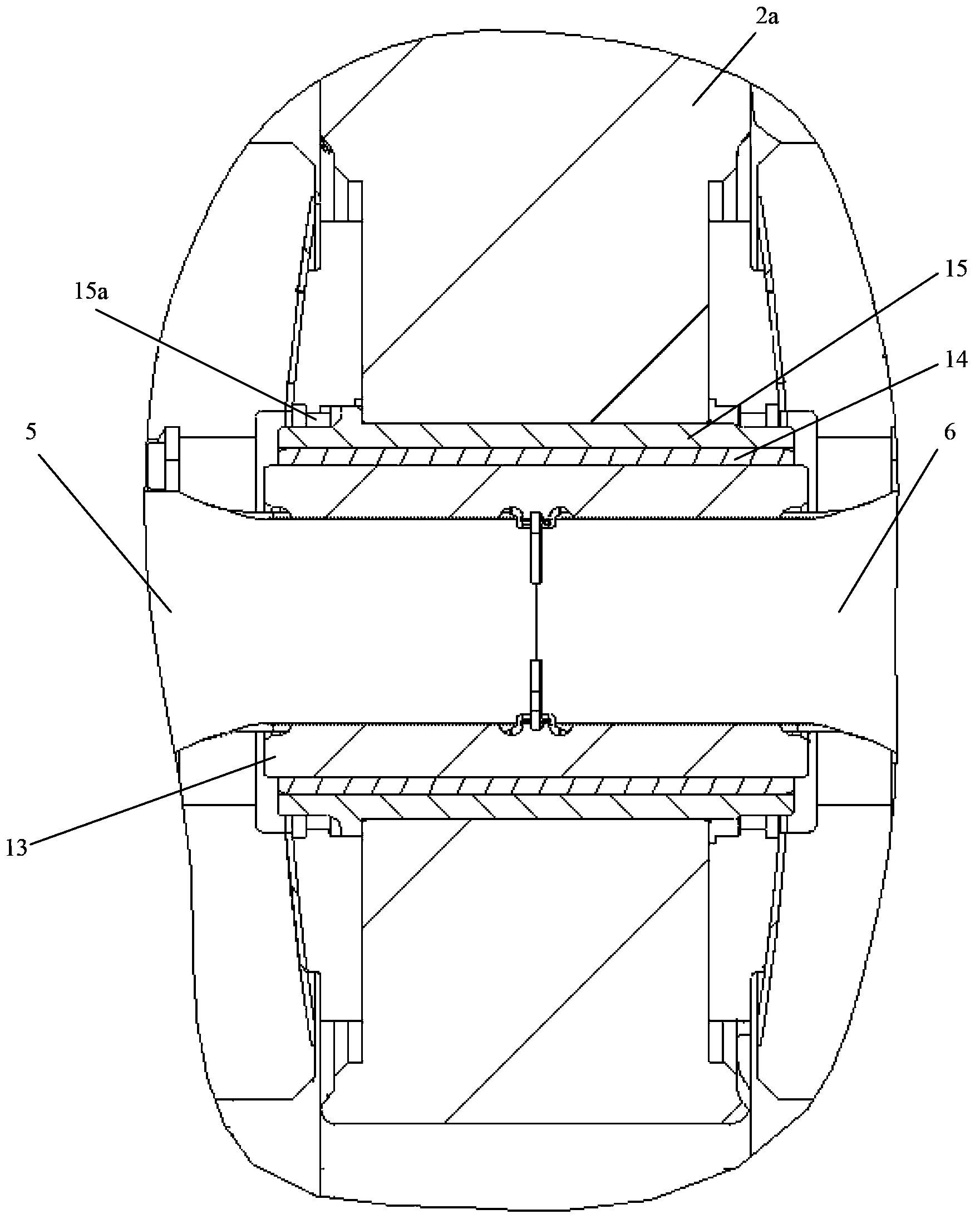

[0024] figure 1 A schematic axial sectional view of a hydraulic pump 1 according to an embodiment of the invention is shown. The hydraulic pump according to the invention can be used in harsh machinery such as excavators.

[0025] like figure 1 As shown, a hydraulic pump 1 comprises a housing 2 and end covers 3 , 4 mounted at both ends of said housing 2 . Two rotating shafts 5, 6; two rotary hydraulic cylinders 9, 10; and two swash plates 7, 8 for driving the rotary hydraulic cylinders are installed in the housing 2. The swash plates 7 and 8 are used to adjust the working strokes of the rotary hydraulic cylinders 9 and 10 respectively.

[0026] The two rotational shafts 5 , 6 are arranged coaxially and their op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com