Full film type wall angle pipe hot water boiler

A hot water boiler and membrane wall technology, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of easy overheating at the bottom of the boiler shell, high boiler steel consumption, and reduced boiler output. Achieve the effect of avoiding low temperature corrosion and ash blocking, low maintenance cost and saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

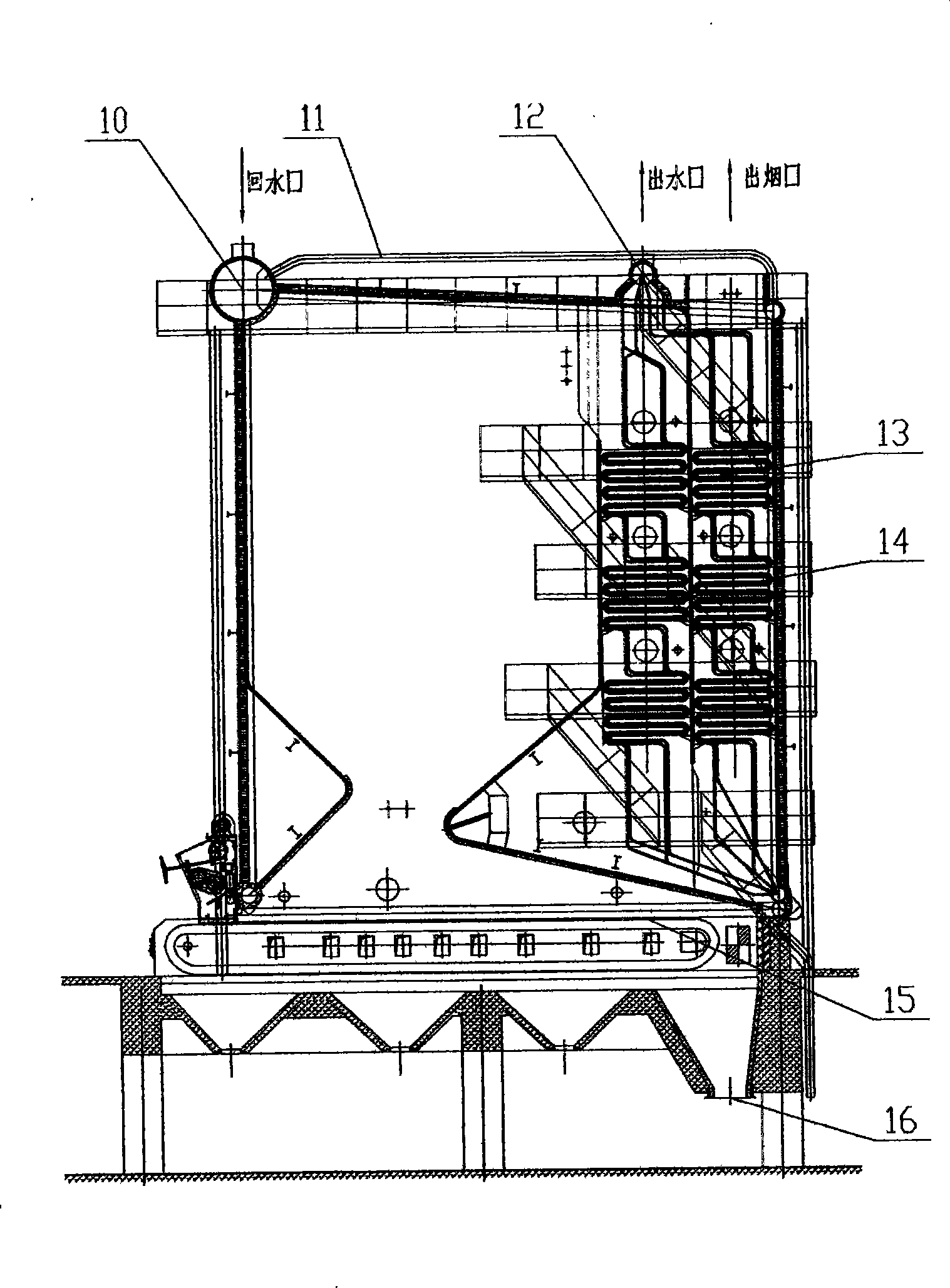

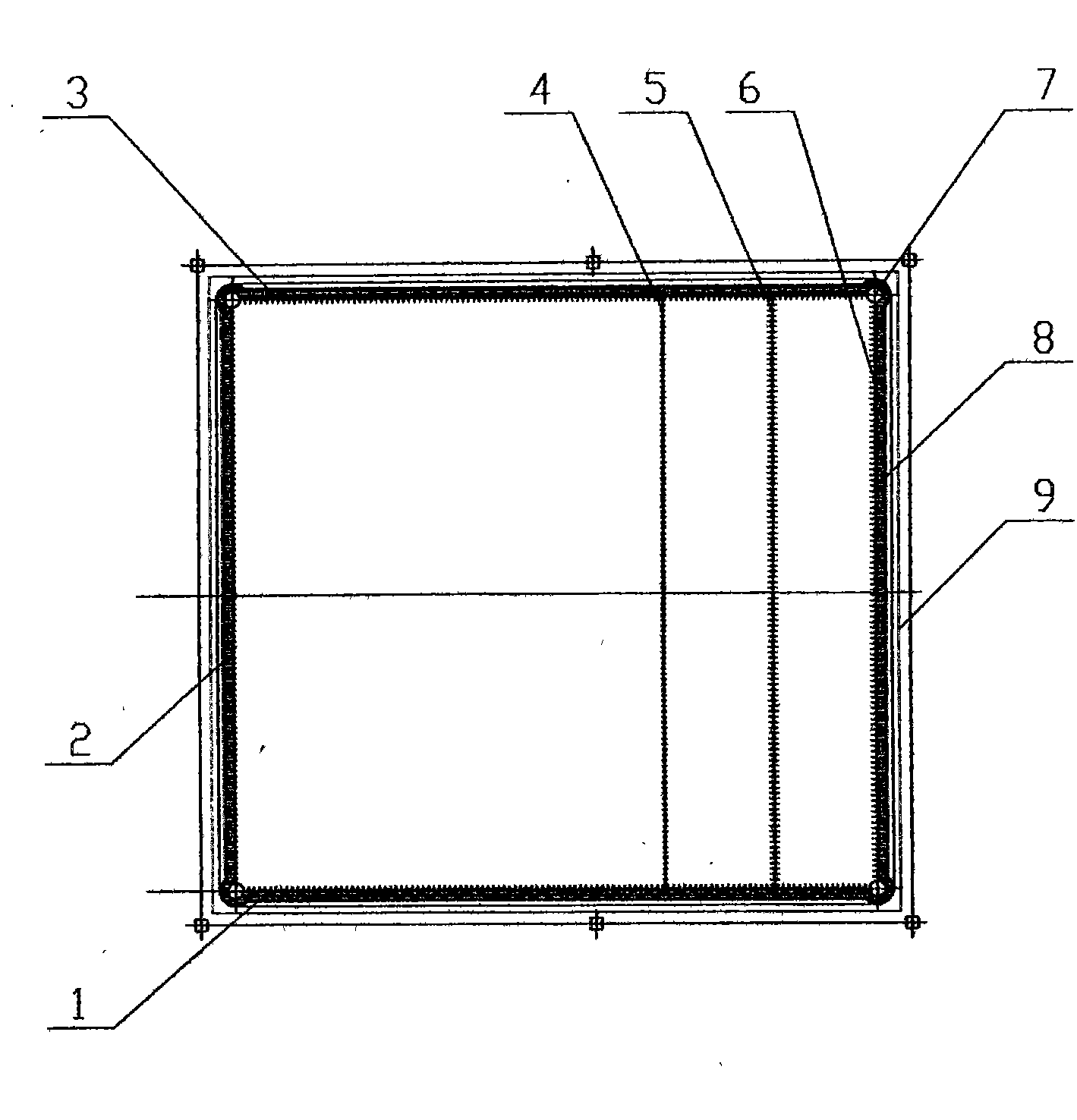

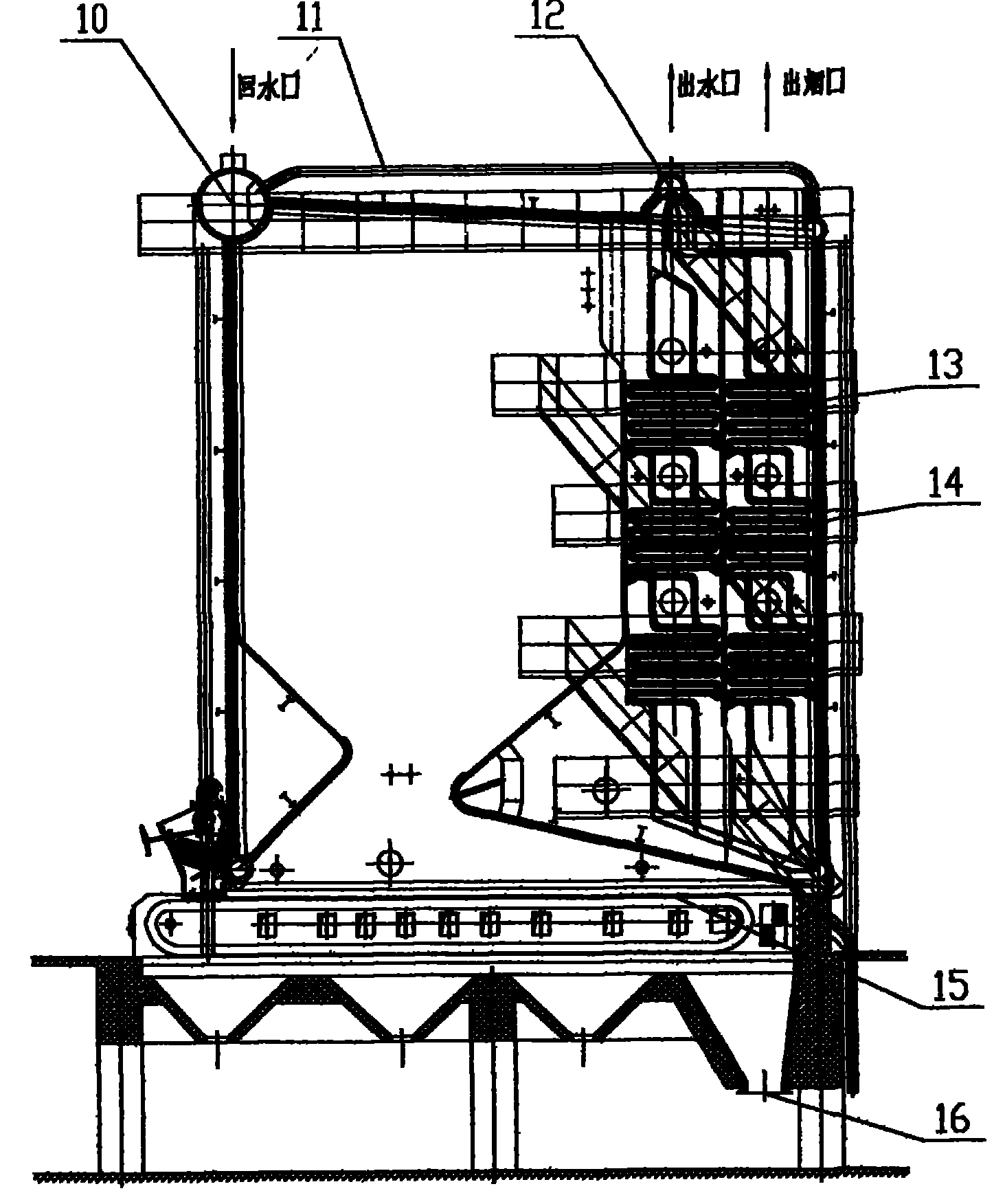

[0011] The full-membrane corner tube-type hot water boiler of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 , figure 2 , the full-membrane corner tube hot water boiler of the present invention adopts a full-membrane wall structure, that is, a closed water-cooled structure is formed around the boiler, and the right wall-type water-cooled wall is arranged around the boiler. 1. The front wall-type water-cooled wall Water-cooled wall 2, left wall-type water-cooled wall 3 and rear wall-type water-cooled wall 6, furnace wall 8 and guard plate 9 are set outside, corner tubes 7 are set at the four corners of the boiler to support the boiler, and the boiler drum 10 is arranged horizontally on the boiler On the top of the front wall, the outlet header 12 is arranged on the upper part of the shaft I serpentine tube economizer 13 and the shaft II serpentine tube economizer 14, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com